Rocking Chair: Episode 3

Posted 19 October 2016

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

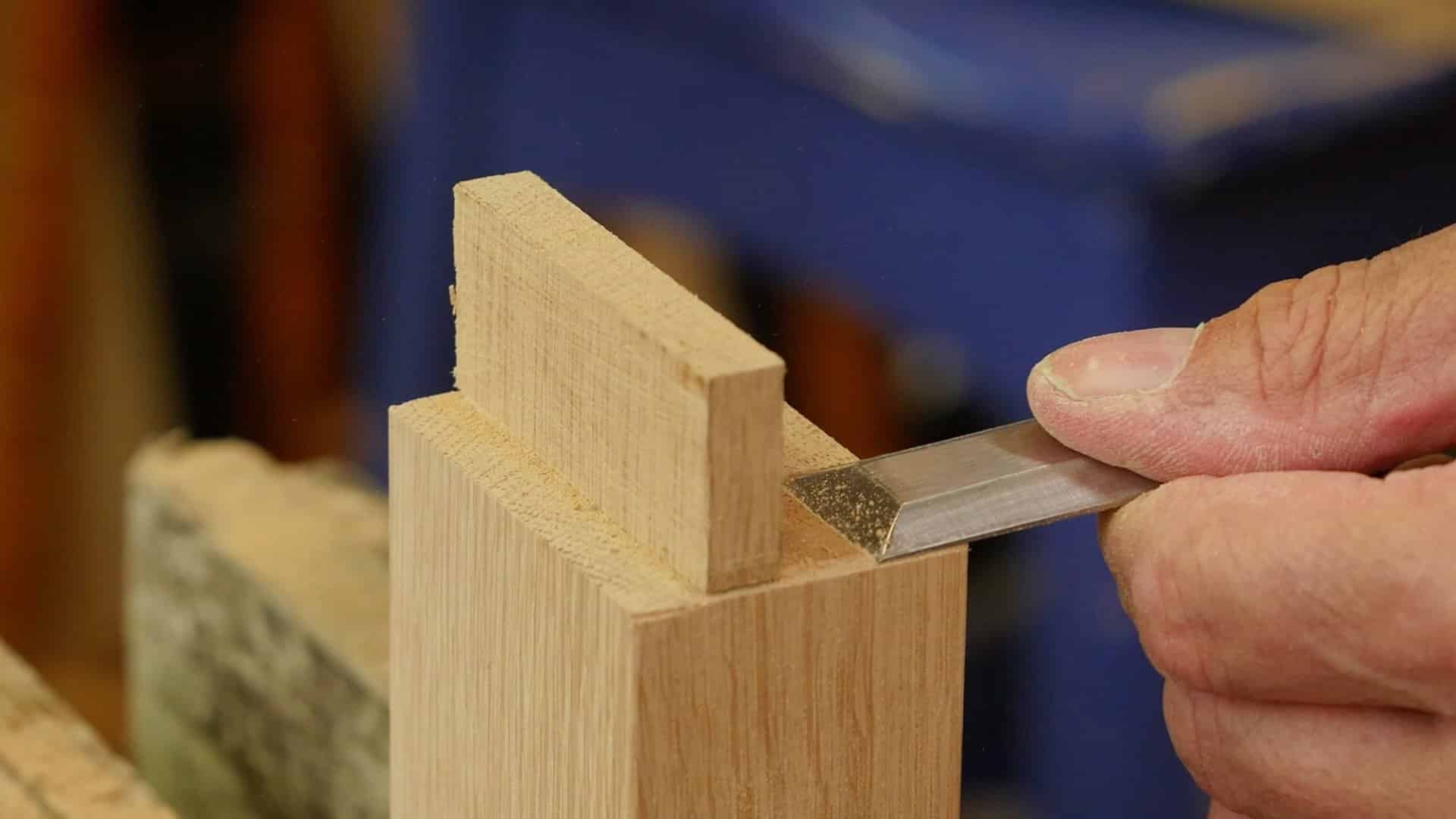

The first step with the back frame, is to layout and cut the back legs to the correct shape. This prepares them for the layout and cutting of the mortises for the back and side rails. With the mortises cut, Paul moves onto laying out and cutting all the tenons for the back frame, paying particular attention to the offset tenon on the back support rail.

Wow, those are the fastest mortise and tenons ever! 🙂 It’s actually nice to see Paul (even at fast speed) just get to work and cut all those joints. Sometimes I need to see that to remind myself that it can be done. Excellent series.

Glad to see Paul also forgets about his beverage on the workbench while he’s in the zone. Can’t even count the number of beers that have gone flat, tea that’s gone cold, or coffee full of sawdust and wood chips…

I really enjoy these time lapse style videos where we get to truly see the entire process. Wonderful stuff, guys!

Haha! I can’t remember the last time I took a second sip of hot coffee while in the shop. By the time I get back to it, it’s long gone cold

yup

The template he uses for the legs, it kind of looks like plywood. Does anyone know if that is true?

Without looking at it and out of my box I would say it is not important. I would not use softwood, but ANY wood will do as long as it is even. So it could really be used as template. In case of doubts shavings with the No 4 helps.

Paul often uses plywood or foam core.

Best

wow wow wow , this is a fantastic project so many complex aspects broken down into bite sized pieces, with the fear removed Thank you

Really enjoying this project, and the production efforts, the music and the time lapse. I for one love the format and style you have created.

Awesome, and thanks to all involved from Greg doing the drawings to all involved in making this come to life for us all.

BrianJ

Who does the guitar music, it’s great!

Hi Mark,

A musician called Henry Horrell who was local to us in North Wales.

I’m really enjoying the series! Thanks to everyone involved in producing these segments!

Why not make a story stick or 2? Seems a perfect application for them.

Great job, Mr. Sellers. I really love your way of woodworking. On watching this project (as the previous ones, too) , I suppose you choose White Oak as the main wood to be worked. Actually, it’s one of the most appropriate woods when joining and sawing (also one of my favourite woods, together with Red Oak, Slavonian White Oak, Beech, Ash, Walnut and Cherry as hardwoods. All kind of Fir and Pine as softwoods). Maybe, is there a particular and appropriate wood for such kind a project? That is, shall we always be careful when choosing woods ?

Hello Guiliano,

Paul is going to discuss options in the upcoming Rocking Chair Q&A 1

In the video he measures 31 1/4″, but the drawing shows 31 3/4″. I assume that is a typo in the drawing. Also unless I’m measuring incorrectly, the piece of stock he is using is longer than the 45″ shown in the cut list. I’m going to err on the side of caution and start with a 47″ length of 8/4.

Hello Dusty. You are correct, it should be 31 1/4″. We will correct the drawings asap.

As for the rear legs, Paul is using a piece that is longer than the 45″ stated, but only as he has a longer piece which is cut to length later. 45″ is sufficient for the length required.

Thanks for the questions.

Phil

Thanks, Dusty. I have been stalled, trying to figure that out. Does Paul’s son monitor these discussions?

@dicksters Do feel free to email through the contact tab. Happy to help.

Thanks, Phillip. I’ve finished the front assembly and now approach the back, where my issues lie. If I can’t figure it out, I’ll email you as suggested. Really appreciate the help.

thank you for the lesson.

Hi, I was just wondering about the dimensions of the bottom part of the back leg, on the drawing the dimension given from the knee to the bottom is 11 3/4″ or 298.5mm but on the video no3 paul mentions 14 1/2″ or 367.5mm I was wondering which is correct? I note that the 14 1/2″ would make the front and back legs more even.

Thanks paul, really enjoy this project

Cheers Julian

Hello Julian,

The final measurement is actually 12 ¾” and will be corrected on the drawing. This is also discussed in the soon to be released Rocking Chair Q&A 1.

Many thanks, Phil

Wow – I’m not a contrarian, but my several tests suggest 141/2! What am I doing wrong?

@dicksters Have you seen Rocking Chair Q&A 1? Paul discusses it there. If you have any further questions after that, do feel free to email us through the contact tab at the top or ask here and I will get back to you.

Your input is wonderful, Philip, but I’m dimwitted and don’t know how to find Q&A 1. I’ll bet you can tell me…

You can access it through the project information page, where there is a list of the episodes including the Q&A:

https://woodworkingmasterclasses.com/videos/rocking-chair-info-page/

I’m looking at the drawings and the width between the front legs and back legs, which don’t match – I would expect them both to be either 19.5” or 17”. The cutting list shows different lengths also. Paul doesn’t mention which measurement he uses in the video. Am I missing something here – if these distances are different, the frame won’t be square, but Paul seems to line them up for square and cut them square.

The back legs are indeed closer together than the front and the frame is not square as is common with chairs. What is unique about this design is that the mortises and tenons are still kept square and back and front are matched by bevelling the frames. Made possible by the use of flat stock. Paul does highlight this point and its also in the descriptions. Follow the videos and you will see how its done.

Oops, ignore all that — I’m in the midst of the latest project and was thinking something else 🙂

Hi Tom,

Paul says:

The front frame is wider than the back frame, hence the two dimensions.

Kind Regards,

Izzy

Very enjoyable. Out of curiosity, during the time lapsed stuff are you also still talking what you are doing? How much do faster can you work when not narrating?

Thanks Julian for your mention of the differences in the drawing and in the video. I corrected my drawings. I consider the video as correct.

Paul, I am enjoying the rocking chair series. I am in a hand tools interest group in my guild and we make community projects and personal work practicing your style of using hand tools. Reflecting back on the last year, this group has changed the way I approach woodworking THANK YOU!!!

Paul, I saw on your blog that you are doing the fast forward portion to show that you are not using any power tools between the shots. I would like to see the entire version as I really enjoy watching a Master at work. Every thing you make seems easy, but it really is not at least for me. I’m trying to learn as much as can by watching you. When you are going on fast forward, you believe to be removing the boring portion of your show. But for me, you are preventing me from learning even more, Given that you have the footage anyway, maybe you can have both version available on your site. I simply love watching a Master at work. I can only dream about reaching your level of expertise. Please, continue to provide us great project.

I love this project! I am building along with the videos – I am about about one episode behind in the build.

Questions on drawings:

1. Page 3 – on the location of the “knee line” on the back leg. On the drawing it shows 31-3/4″ from the top end of leg to the knee line. However in the video Paul says and measures 31-1/4″. When I do the math it is 2″ from knee line to Lower Rail (+2-5/8″) + 23″ between rails + Top Support Rail (+2-5/8″) + 1-1/4″ (which is from top mortise which with a 1/4″ shoulder would be 1″ from top of rail to top of leg) = 31-1/4″. Can you clarify which is correct? 31-3/4″ or 31-1/4″

The 23″ between rails (or 23-1/2″ between mortises) is not on the drawing.

2. page 3 – What is the radius of the arc on bottom of Top Rear Seat Rail?

3. Page 1 – What is the radius of the arc on bottom of Top Side Rail?

4. page 3 – Cut list says the slats are 9/16″ (14mm) square. Note at the top of page reads 1/2″ (12mm) square slats

Comment – part of the “confusion” in reading the drawings is that some measurements are to top/bottom of mortises and other measurements are shown to the top/bottom of rails…

My apologies for the long comment.

Hi All, these last few questions and many others are going to be addressed in the soon to be released Rocking Chair Q&A 1. Thanks for your patience.

I don’t build everything Paul presents in these series. I get just as much pleasure watching him work – at any speed. The love and craftsmanship is palpable. And when I do actually work on my own projects, its like he is standing right next to me, guiding me, working on ‘Acura’ and precision.

I’ve never had a better gift.

Thanks Paul.

I am using white oak. The hardest white oak I have had to date. My Stanley’s dull quickly and the tools are pretty good ones but old. I have some really old wooden skewed rabbit planes and those work the best on the wood I have. And that old steel does not dull as quickly as the newer blades. I finish with the Stanleys.