Dovetail Boxes: Episode 1

Posted 2 January 2013

This is an episode in a free series. Want to watch it? It is free to do so, you just need to log into the site, and you can enjoy this video and many other videos we think you will love.

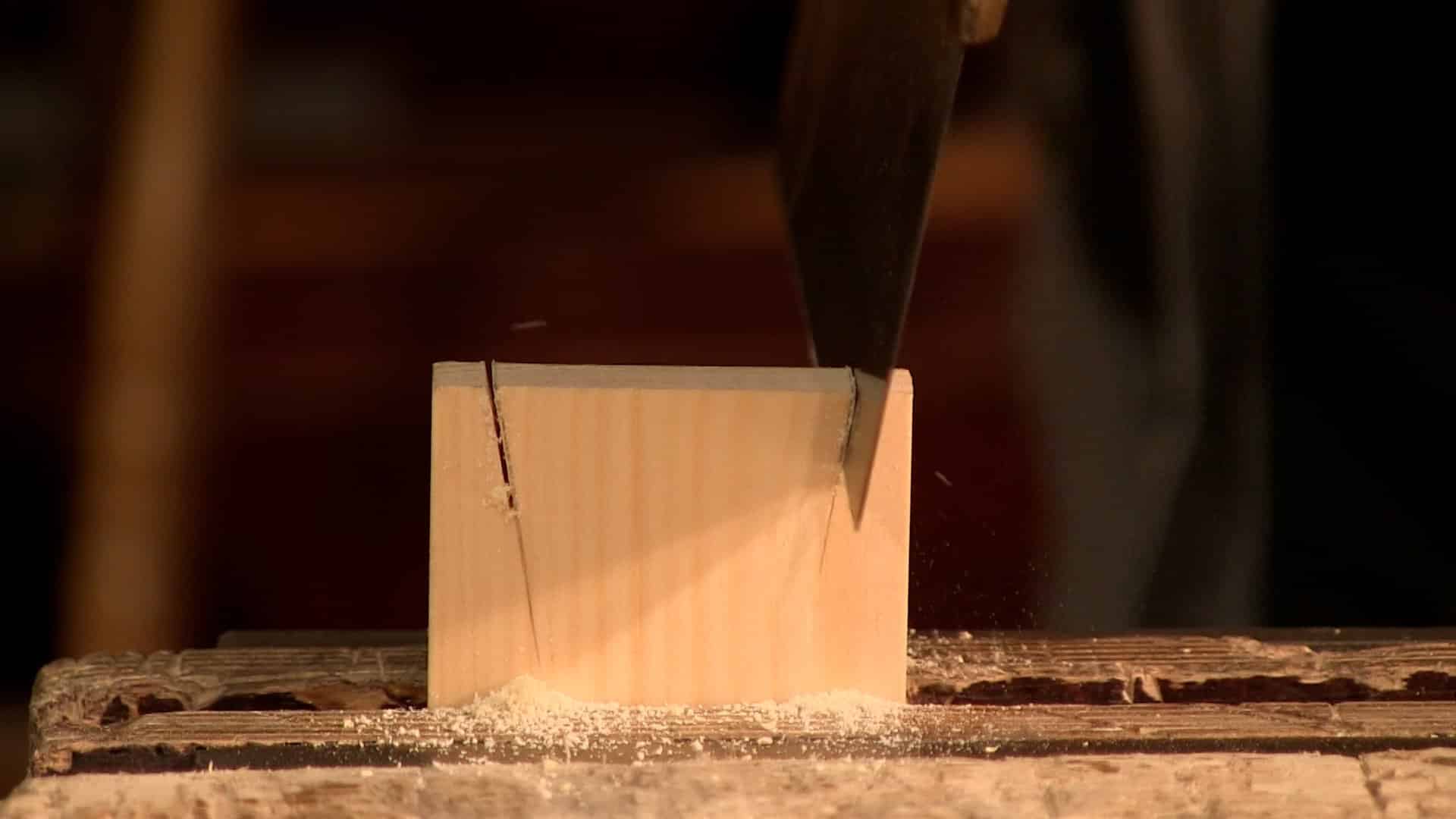

In this first episode, Paul shows how to prepare the wood and cut the tails for the dovetails. These steps will be repeated for other boxes in this series. Paul will show how the basics can be adapted to more complex projects.

Thanks guys, this is going to be a great project

Thanks for the new episode! Looks like some really interesting projects in this series – I love the beading and sliding lids.

However, I can’t help but feel like you should have at least included cutting the pins in this episode. I honestly thought there was a problem when I saw the video was nearly finished and Paul hadn’t finished one tail yet. It’s quite a change from the pace of the tote series and may be a frustrating week of cutting only tails for some people!

The production quality is top notch as ever. Very detailed views so you can really see what’s going on.

George.

laffs! (George)

I don’t know about you but, I’ll be busy enough trying to get my pieces of wood to the correct dimensions, then cutting the tails. I’ll probably just about be ready for the “tails episode” next week. (if all goes well.)

I think the home centers sell pine in 1/2″ thickness. if not, I’ll have to figure out how to get the 3/4″ down to that thickness. The only way I know of (via hand tools) is re-sawing. Either that or a whole lot of planing. 🙂

Hi Paul,

Do you ever gang saw the tails? Any thoughts about gang sawing them?

Paul,

I too would like your thoughts on “gang cutting” the tail boards. Do you recommend for or against it?

Is it just me? Or am I the only one at the end of the video’s saying to myself AHHHhhhh! I can’t wait till the next segment. These boxes are going to be very useful. Another Well done video, Thanks

AHHHhhh!!!!

I’m working an a set of Bed Steps, and hand cut some dovetails today. Now I wish I had seen this first! Oh well, I’ve learned something new today,

I’m looking forward to the rest of this series. Nice job Paul!!

Excellent first episode for this new series – should be a fun winter. And why is (was) working wood an avocation, not an occupation?

(Kelly) – the large home centers in my region stock poplar and oak in 1/4, 3/8 and 1/2 inch thickness, and varying widths from 2″ to 6″ in 2 , 3, or 4 foot lengths, perfect for the dovetail projects.

Yeah Mark, I bought some tonight. In fact, considering how often I mess things up, I bought enough to make 3 or 4 boxes! That way I’ve got some spare parts. 🙂

Thanks Paul. I learn something new every time I watch one of your videos, even though I own and have watched your DVD collection repeatedly. For example, I’d been sawing parallel to the surface thru the entire board with mixed results. Dropping the hand down and following the edge mark down after getting into the knifewall a bit should MAKE you saw in the correct plane since you’ve now established 3 points or guides on the cutting plane, if I’m understanding that correctly.

Question: What does pinching the plane end while planing the last pass on the edge accomplish? I’ve watched it twice now and understand your finger is a guide, but why do you need that?

For all who are going “Aaaahhhh”, I understand. I watched his entire DVD set in one sitting and after countless hours, I still wanted more. It is addicting.

HaHa, I love watching them too Jeff. Using the finger as a guide, helps keep the plane in the centre of the board and getting a square edge

Thanks Ken. Boards still too short? 😉

@george (and others)

I realise that the timing of the ending is a bit annoying but there was just no good place to stop! Paul was on a roll and we had about an hour of near continuous footage. The cliffhanger ending was not on purpose or to keep everyone in suspense 🙂

@jwinship,

Paul is away and it may take him longer than usual to see this and reply. @ken is right. Also it helps to keep your hand out of the way so that you can see better.

I am sure Paul will eventually get to answer this himself and perhaps give a fuller reasoning.

I love these projects ,they teach you (me) the skills you can use on almost any project from small to big pieces.

Jeff,it sure is addicting ,after seeing a video i can’t wait to do something in the shop,but as this is more than often in the evening this is impossible,so i put in another video or watch one from these classes and it starts al over again,love it.

I enjoy these kind of projects and have many to make, so seeing this using hand tools only is very enjoyable.

Thanks Paul and Joseph you Guy’s are nailing it. I am really enjoying this on line school, since logistic’s does not allow me to attend any live schools.

Steve

Did episode 2 get taken down? Could’ve sworn I saw notice in my in-box.

Must……have……more……coffee.

Episode 2 is up now. But it certainly wasn’t two days ago… Enjoy!

Paul referred to a chisel box with a fitted lid in the first video that he would get back to later. I would like to know how the lid is fitted to the box. An email with instructions will be enough for me. I was just wondering how he would had done it. Thank you, Gene

At 1:05 I can see 1/2″ wide rabbits sawn on the two short sides of the lid. I imagine they are marked and cut like half a tenon.

I like the larger video viewing window (box).

Makes sense to me. How about an incentive… If I am a paying member for 12 months I get a free down load of any series I chose…. Hey I gotta ask… I’m all about great deals… :-).

I was just kidding. Joseph has been good to me and I consider just being given the opportunity to learn these techniques worth more than I am paying now.

Keep them coming and I keep paying..

Hi @heath,

We had a temporary issue last night for a few hours. Sorry about that. It should be fixed now. If you want to get in touch in future about a technical issue please click ‘Contact Us’ on the main menu or hover over ‘Forums’ and then click ‘Site Technical Support’.

Excellent. Thanks Joseph.

Where i would reach for a piece of paper, Mr. Sellers takes notes on a piece of scrap wood. It’s all about the mindset.

Well, well, well. I got my boards all cut to size. Had some pieces of 1×3 pine left over from making my wife a trellis. Exactly enough to cut out the four sides with 1/2 inch left for squaring and kerfs. Here in the states a 1×3 is actually 3/4″ x 2 1/2″, so I did use my table saw to rip it to 2″ and resaw that to 1/2″. But after that, it’s all hand tools. Planed everything flat and square, cut everything to length and cleaned up the cuts with the plane. Amazing. I’ve watched so many hours of Paul’s videos in the last couple of months. Great to put it to use. Every time I skip over something he says to do, I regret it instantly, then do it next time and, yup, he was right.

So I have four straight, square, perfectly matched boards. Now, let’s see if I can pull off a few dovetails.

I found that if I saw dovetails in both boards, just as he marked both boards together, my dovetails turned out much more square to the ends. Is there a reason you didn’t do that?

It’s not really a good habit to gang up dovetails even though some things seem to make sense. In your case you say that you put the two boards together to saw them and it worked best for you because you got greater accuracy. You don’t say how many times this worked well for you. Was it luck or good management? In many cases ganging them up together can result in both dovetails being out of square or misaligned or both and thereby the two dovetails end up being different sizes. Also, the very practice we need when we begin dovetailing is denied by introducing something we never really do in practice. You can end up doing half as much practice as others when we advocate more practice for the establishing of skill when perhaps you want less? repetition makes the task less monotonous to the degree that I often if not mostly cut my dovetails freehand and without any measuring at all.

Thank You WWMC Team!

Don’t know how many hours of video I’ve watched of Mr. Sellers marking, cutting, planing and gluing. The interesting thing is I haven’t ever seen him use anything but the #4 smooth plane. It all looks so effortless, until you try it.

Used a smoothing plane on the stock of wood and now have ordered a Jack plane for removing large quantity of wood. Getting it down to 3/4 inch. Am making the first box and then will go to the sliding lid box.

The videos are superb, though I have made dovetail boxes before, the quality and finish in these are heavenly. Pauls explanation of everything is quality time.

Glad you like the videos. It’s also worth having a look at the video on adapting a blade to use as a scrub, as that helps remove material very quickly: https://woodworkingmasterclasses.com/2014/05/scrub-plane/

I’d like to practice my dovetails, so I’ve been looking around my home for things that need boxes. One of the things that desperately needs a box is rather large and would require interior measurements of 19×13 in. with a heights of 7 in. Is this too large for this type of construction? Could I plough a groove around the bottom and insert a plywood bottom into the groove instead of attaching it to the bottom? Thanks

Erin,

Those dimensions are not too large at all.

Keep in mind that you’ll need to add 2x the thickness of your stock to the length of the sides and ends to finish out at the required inside dimensions (but you already knew that).

In addition, with through dovetails the groove will produce 4 holes on each corner that will need to have a sliver of wood carved to fit if you want a clean appearance. Paul shows this in one of the box videos, but I can’t remember which.

Best,

Craig

At 19×13, yes, I’d put the bottom in a groove to allow for movement and would avoid simply gluing it rigidly to the bottom of the box sides. If the bottom would be satisfactory to you if placed in just two grooves rather than four, then you can run the grooves in the tail boards only and place them so that they land in the gaps where the pins go. Then, when you assemble the pin boards, they will cover the grooves.

Thanks @Craig and @ed. I hadn’t thought about a gap showing, so I’ll be sure to plan with that in mind. I think running the groove on all four sides will be my best option since this box will hold my children’s marble run. At some point, I’m guessing it’ll become a car or boat.

@ERINWEED you made me curious, so I looked for ways to hide the grooves. One clever idea is described here, although briefly:

http://www.theunpluggedwoodshop.com/a-cabinetmakers-toolchest-part-five.html

Between the text and the video, it may be clear.

I’ve never tried this, but I don’t see why, as another alternative, you couldn’t arrange the groove to come out between the pins so that the tail hides that groove. Now, you’ll have a groove coming out of your tail, but just do a half-lap dovetail like you’d do on a drawer and that will hide the tail groove. Hope I got that right. The only problem I see is that it might make the bottom waste a lot of space because the groove will need to be pretty high up. Guess you could do half-tails?

Look around and you’ll find a bunch of ways!

While I know this is an older video I still cracked a smile as Paul reached for a piece of scrap wood upon which to notate measurements.

I learned the same thing from my Grandfather 55 years ago. My son & grandson have learned the same.

Thank you Paul.

Would it be possible in 1/4” stock?

Hi Sergey,

Paul says:

You can make it out of any size you want, just go for it.

Kind Regards,

Izzy