Occasional Table episode 8

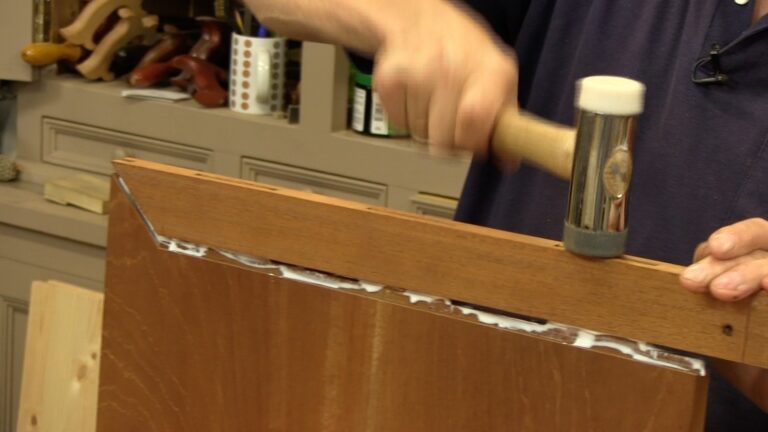

In this final episode, Paul does the final preparation for and glues up the breadboard end, including wedging the tenons. The table top is then ready for the final shaping including rounding the corners and surface planing. Once he has attached the table top to the base frame, we are at the end of another project.