How would you make this?

Welcome! / Forums / General Woodworking Discussions / Woodworking Methods and Techniques / How would you make this?

- This topic has 11 replies, 6 voices, and was last updated 7 years, 9 months ago by

mxbroome1.

-

AuthorPosts

-

How would you fabricate the item in the attached drawing? The grain is running along the length. Six of these will be glued up into a hexagonal tube, so this is a bit like coopering. The issue is that the piece is small. If something like a donkey ear is made to get the 60 degree angles, I’m afraid the part will wobble in the donkey ear since it sits on that narrow 1″ foot. Clearly, one of the angled faces can be sawn and then trimmed in a donkey ear while you have your long stock, which solves the wobbling, but then you will cut the part off and have to trim and true the second edge, and now the part is small. Clamp a block in the donkey ear so that part is supported on its 1″ base and along the 4″ side maybe?

16 June 2016 at 5:49 am #137856

16 June 2016 at 5:49 am #137856A donkey’s ear would be a good solution. But before I read it I was thinking of sawing the angles close to the lines and planing to the lines. The challenge comes in planing a piece that size. Perhaps you could double-sided tape the piece to your bench top so it just overhangs the front of your bench, plane to the lines, then flip around and plane the other side. You may be able to do the angled end this way as well.

Good luck!

16 June 2016 at 9:41 am #137858

16 June 2016 at 9:41 am #137858Could you not trim both edges in the donkey’s ear before cutting to length? Otherwise making a miniature one to purpose is the only thing I can think of. All the best.

[quote quote=137858]Could you not trim both edges in the donkey’s ear before cutting to length? Otherwise making a miniature one to purpose is the only thing I can think of. All the best.

[/quote]

[quote quote=137858]Could you not trim both edges in the donkey’s ear before cutting to length? Otherwise making a miniature one to purpose is the only thing I can think of. All the best.

[/quote]

Cutting to (near) length I think will make it easier because it shortens the lever arm that is racking the piece when the plane applies pressure. Four inches isn’t terribly short. I’d agree with you if these guys were only an inch long!

Matt….maybe clamp the plane in the vice and move the piece over the plane…?

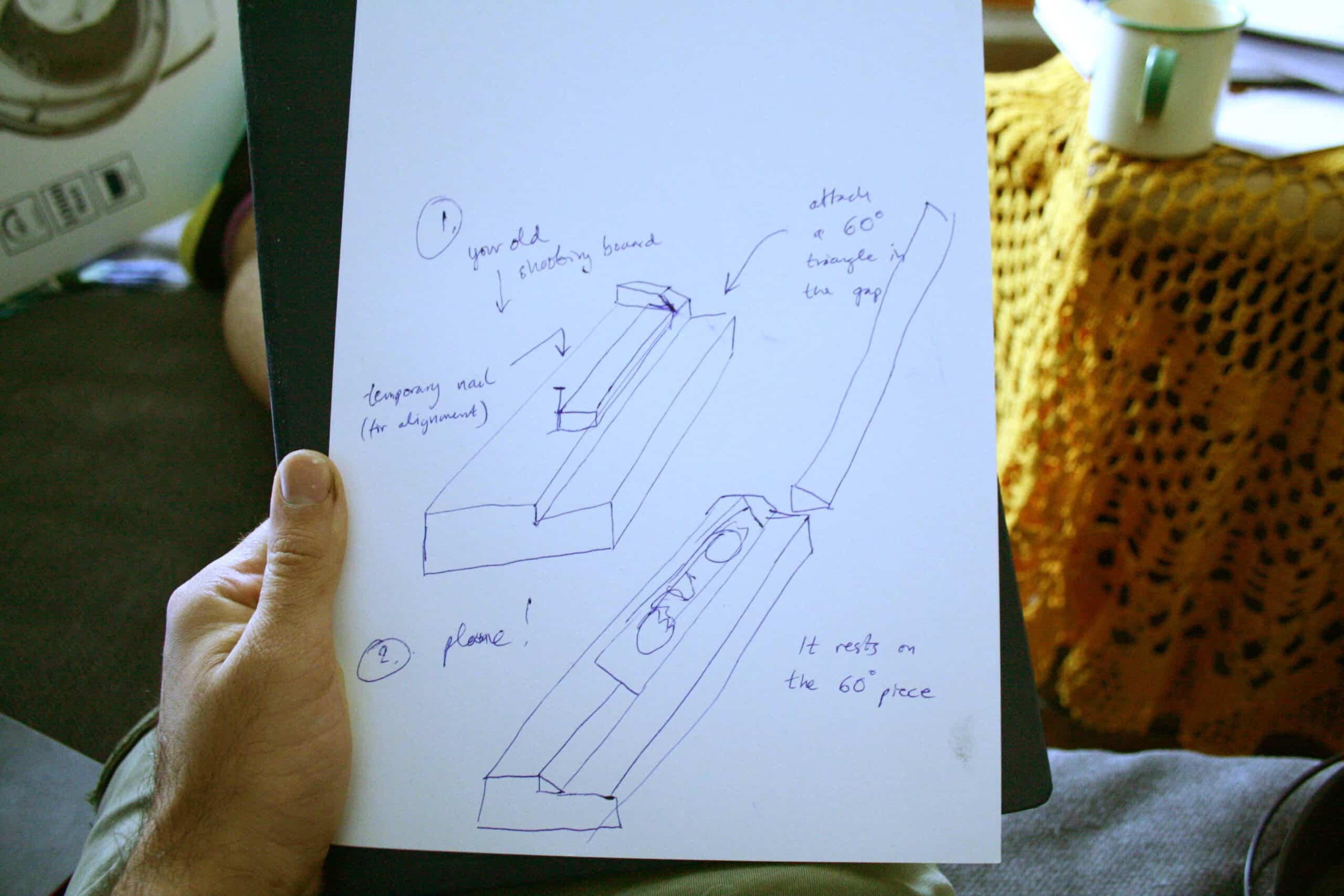

I made something similar with a 45 grade angle along the grain on two sides of a piece. The piece was 5 inches long. I used the shooting board and added a small triangular support all along the step-down of the shooting board.

Like this:

Then i put a bit of tape on the blade of my plane so it didnt eat away on the triangular support.

When first making the triangular support (60 degrees in your case ) i just sawed it carefully.

-

This reply was modified 7 years, 10 months ago by

laxmodin.

-

This reply was modified 7 years, 10 months ago by

laxmodin.

Attachments:

You must be logged in to view attached files.@laxmodin, thanks for the idea. Two questions. 1) Is the nail holding the piece being worked tight to the shooting board fence or is it on the back side of the piece being worked, keeping it from being pressed back away from the plane? 2) When you do this, doesn’t your shooting board fence get trimmed down to the angle of the plane? So, you’ll need a new fence to go back to 90 degrees?

#1. I put the nail there to make sure i held the stock square to the fence. Since the stock was so short, it became wobbly for me without a guide. Was i even more careful than i had to be, i would nail or tape a small temporary board in place.

#2. I made a fence with a Tapered 45 degree edge for the plane to run over. Took me no time with a saw and two guidelines.

-

This reply was modified 7 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.