Linen Cupboard: Episode 2

Posted 30 September 2020

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

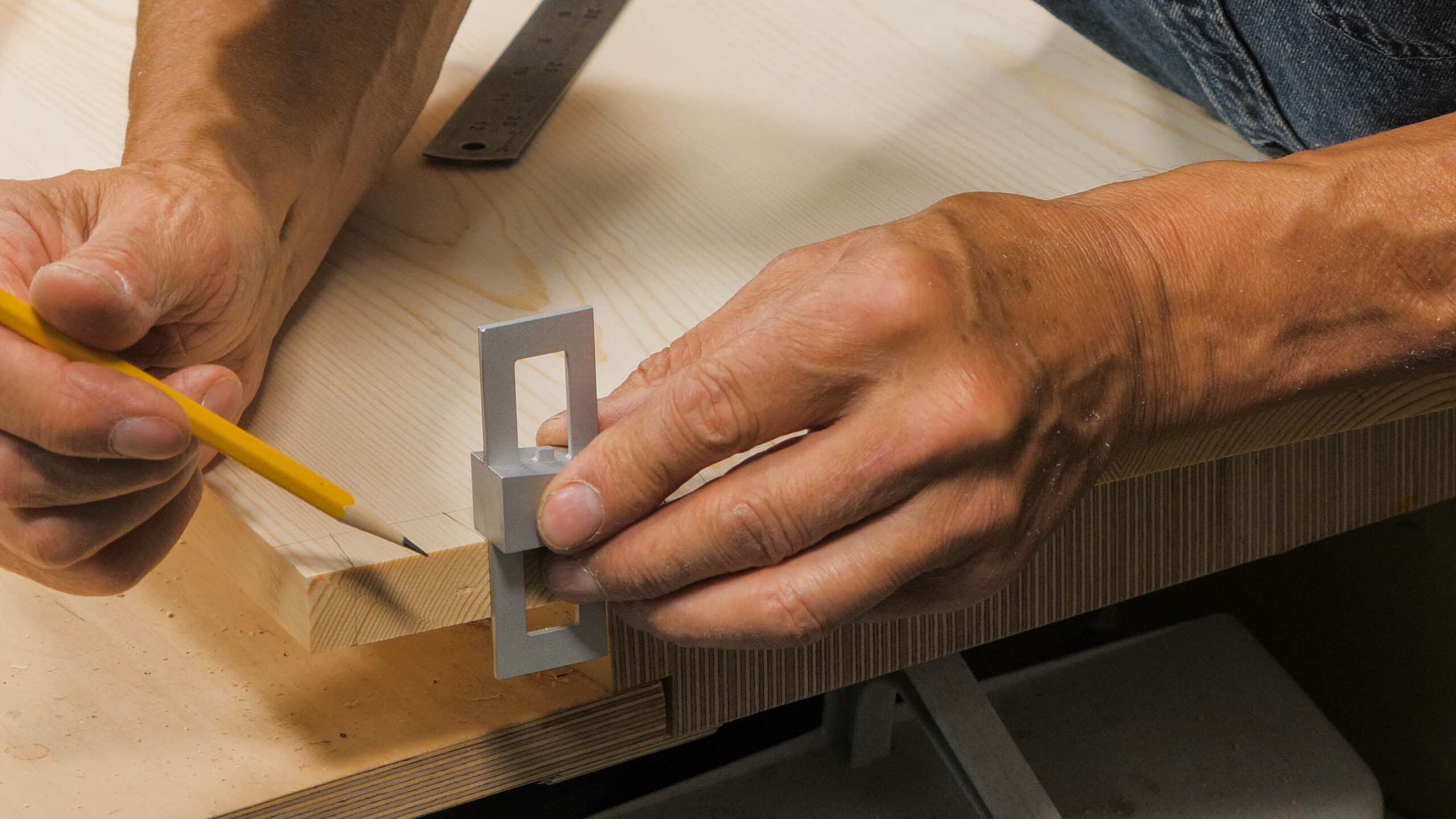

The importance of accuracy should never be underestimated and, with hand tools, we must work at coordinating our effort with intent. Paul wanted to focus on what he does to minimise the risks in his joinery and this video is half-dedicated to this important section. We do hope that you will enjoy the efforts Paul put into this. Paul takes you on to the first steps for laying out your dovetails in detail and the theme of accuracy is woven throughout because accurate dovetails remain the signature of fine box making no matter the size of the box.

Nice to see you are back on a larger project again.

Thank you

Thank you so much. I am and have learned so much from listening to and especially watching you work.

What can you tell us about the new dovetail gauge?? Where can we get one? I’ve made the wooden one from your video. But can always use another.

Hi @LARRYC and @DOUGLASALAN89

Paul says:

I wanted to design a dovetail template based on my wooden one but from anodised aluminium. I have one made from titanium but it’s 50 times heavier than anything I anticipated. A friend of mine has a milling machine and the equipment to make these for me so I ordered half a dozen and have been testing this one out for a month now to see how it feels. I have thought about producing them for sale and feel like it would be a great dovetail template for anyone to own. Watch this space!

Kind Regards,

Izzy

I’ve been a member for a handful or two of years and I see an underlying theme in all Pauls videos, be they YouTube, free or paid that I don’t see demonstrated ANYWHERE else. In this video it was verily shouted (at least to me). I understand this video is about accuracy but what was shouted is the respect and affection held for the materials and tools by the gentleness and mastery in-which they are handled. This is something I have not witnessed of anyone else.

Full respect and thanks to Paul.

I agree with Doug K could not have said it better.

I’m in agreement with Doug K also. and Larry C had a good question also. I would like one of those new dovetail gauges as well.

Thanks Paul. I appreciate that you are taking the time in this project to go over the dimensioning of the wood. There are a lot of lessons in there for us. It also helps me feel normal when I encounter these and know you see it as well. I especially liked when the wood was too wide that you first scribed and deepened on half before putting pressuring and doing the second half of the width. I have had a few wider projects and tried to put the knife line all the way across and it’s been difficult. It never occurred to me to do it the way you just showed up.

I enjoyed the comments about wood sizing and stock prepartation. I really appreciated your comment about not getting worried about flattening the wide panels because the dovetailing will take care of the cupping. Thanks Paul

An interesting thought – the aluminium dovetail template. The basic design never changes.

I recall that the late Jim Kingshott, who made some of the first instructional woodworking videos in VHS during the 1980s, used an identical template made of 1/4 inch-thick clear Perspex.

It’s advantage was that, when it was placed on the work, previous marks were visible and assisted aligning the template. There was no chance of forgetting to turn it round and marking the wrong slope!

It was one of the first times that I saw ‘super-glue’ – a new-fangled novelty in those days – used to assemble the two parts.

I have made a couple of sets of marking gauges out of aluminium profile. I also got my hands on a Lion Tool Company marking gauge as well (nice piece of kit). The profile ones have a large enough lip that you can mark both the face and the end at the same time.

What a marvelous layout method. Love it.