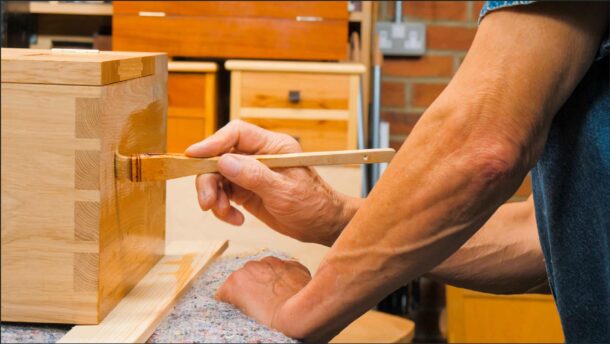

Traveling Joiner’s Toolbox

Posted 26 November 2020

This is the introductory page for a paid video series. Want to watch more of this project? Select the best option below to get started.

When does a piece of work become an heirloom piece?– when it is carefully crafted, with a long term use in mind! This toolbox will last many lifetimes even if it were to be abused by the day to day rigours of daily toting and stowing of your prized hand tools. This is a cabinet course all in one! In this one project, we have door making with raised and faceted panels, mortise and tenons and grooves, carcass construction with dovetails, and then too, drawer making as well. This will be your lifetime toolbox for you to work away from the bench and then too at the bench! Enjoy!

Paul, I’m eager to see this series. While I have a vintage Gerstner toolbox, I’ve been wanting to make my own. This will be fun!

Can’t wait for this one. Thanks for all you do.

Hi Paul what type of wood would you suggest I use for this tool box?

Hi John,

Paul says:

I have a pine one, oak one and mahogany one. I’ve made them in walnut and cherry, they are all good. You can use almost any wood you like.

Izzy

The wood looks like oak, also I think it would make a good choice due to its strength.

I was thinking cherry perhaps would look good …

I am looking forward to this one. It looks challenging but the end product looks really lovely.

Looking forward to this project

“It will last 200 years if you live that long”… Paul, I certainly wish you to live that long! 🙂

Looking forward to this project. I love making tool boxes and I have several grandchildren who need one of these.

Can’t wait to get started on this project.

I had just started getting wood for a tool box but like your much more. I will stop building and start watching. I get so much more from your teaching than I get from discovering my mistakes— thanks so much

Looking forward to another great project!

I’m thinking of making two of these as presents for my twin nephews (they just turned 11). Can I ask how much this one made of oak weighs? Obviously they will soon be growing into whatever the weight is, over the next few years, but I might substitute alder or pine if it is really heavy. Anyhow, thanks for offering this project, it looks like a great one to learn on.

Hi,

Paul says:

I’m not too sure, we don’t have big enough scales here. But you can work it out using the cut list if you like.

Izzy

Hi,

Will you provide links to where you got the hardware from?

Thanks

Darren.

Looking forward to seeing this project. My toolbox will be stationary as I only work on my bench these days.

just started on my box, made the main carcass deeper to suit.

Thank you Paul and Team

I would go for ash.

Paul I have waiting for this project for 8 years. I have seen many versions of this box in boat building shops and wood working schools and home shops. Looking forward to it.

Been waiting for this one.

Been waiting for this one.

I’m with all the others, on this one Paul. It looks like a great project.

I may convince the Mrs too keep this one indoors.

If I’m not careful she may Nick it to be used for some thing else.

Regards Larry.

Quick question: I’ve got some sapele boards that I’ve been saving for something. Is there any reason why I couldn’t use it for this project? A little brittle maybe?

Hi John,

Paul says:

No, it’s great for a toolbox like this, not too brittle. Great wood.

Izzy

What a great project!

Looking at the cutting list to see what timber I will need, I see that the metric width of the rear back panel is the same as the stiles and rails (all 83mm) whereas it should be much wider (211mm?) as shown in the drawing and imperial list.

Thanks.

Hi,

Thanks for pointing that out. We will get that fixed soon!

So excited for this! Been watching it come together. Going to put a space heater in the shop and spend my nights warm and happy in the working 🙂

I am really looking forward to this one. I am also interested to to know which tools you select when you travel, and why.

Thank you for these videos. They are a special treat to me.

cant wait to start this project. I’m just wondering what lock do you use ?

Hi Martin,

Paul says:

I found what is called a barrel lock. These are easy to fit it and cost somewhere around £12 second-hand.

Kind Regards,

Izzy

just finished dry fit of dovetailed case. Working with stringy bark. The hardest wood i have ever used and very unforgiving for dovetai fit.

Really enjoying the challenge

Is it necessary to “upgrade” before getting a copy of the cutting list and links to the hardware?

I would like to have all that prepped before settling down to watch the series and build the toolbox

Hi Mark,

The plans and videos for premium projects are only available with a premium membership.

Kind Regards,

Izzy

Paul thanks once again for the beautiful project . I really hope you will share the project of the new rocker too…

Musing on design a bit – 3/4″ stock, in dense wood (oak or other) will make a heavy box. I would think weight matters for a travel box. At approx 20″ x 9″ x 14″, would 5/8″ stock not be more than strong enough? Thoughts?

Hi,

Paul says:

Yes, that’s obvious to everyone, but who is going to plane ⅛” off stock sized materials at ¾” just to save on something so minimally changed? Please try to remember that these changes can be chosen on an individual level to suit. Also it’s important to remember that many in my audience have access to store bought materials that seem always milled to 19mm or ¾” but do not have any machines. It’s a lot of work to plane this material down by hand.

Izzy

Quite a weight, true that…..

I think that those old-time-carpenters ate all their greens, besides, they probably had a horse and cart.

Then there were apprentices……………

As an ex-apprentice, I can tell you a thing or two about hauling tool-boxes about!

And people helped each other. I never moved my day box by myself.

And when quality ply became available, the construction of those boxes became a lot lighter while remaining as durable.

It looks like an interesting project. I have a suggestion about the drawer slides. I recently built a big toolchest for placement under a bench, and it has two-way drawers that are accessible from either side of the bench . The fact that the drawers are two-way is only somewhat relevant here, but what is relevant is how I made the slides. I made them beveled as you would cut French cleats for hanging cabinets on walls. This method keeps the drawers from cocking in the carcass, and I believe that for the two-way design, that it adds a measure of bracing to keep the drawers and carcass aligned since there is no back panel to stiffen the carcass.

I’ve just ordered up three dimensioned American White Oak planks for this project this morning from McGregors here in Belfast.

2 x 19x194x2440 and 1 x 19x220x2140 should cover it with a bit extra to spare.

Total cost £135 inc VAT.

My question is how does this price compare to what others are paying for similar wood elsewhere in the UK?

@DAVID CROZIER American White Oak is pricey over there. Did you get it Plain, Rift or Quarter sawn as that does change the price a bit.

It’s rift I think.

Paul

I have completed the project and really enjoyed it. is there a gallery location yet?

Phil

Hi Phil,

There isn’t a specific category for this project, however you can upload into ‘other’ and it will be featured.

Izzy

Hi Mr. Paul,

This is such a cool project that I can’t wait to do. I hope it is as fun as all the other projects.

Thanks for a super fun project,

Parker

It is so beatiful – I watched trailer many times already and still enjoying looking at this toolbox.

Are the dimensions of this toolbox published somewhere? Thanks in advance.