My first piece of furniture – sidecar cot in walnut and ash.

Welcome! / Forums / General Woodworking Discussions / Projects / My first piece of furniture – sidecar cot in walnut and ash.

Tagged: ash, dovetails, drawboring, hand tools, mortice and tenon, poplar, sidecar cot, steambending, walnut, wedged tenons

- This topic has 10 replies, 8 voices, and was last updated 7 years, 4 months ago by

prbayliss.

-

AuthorPosts

-

28 February 2017 at 2:25 pm #309609

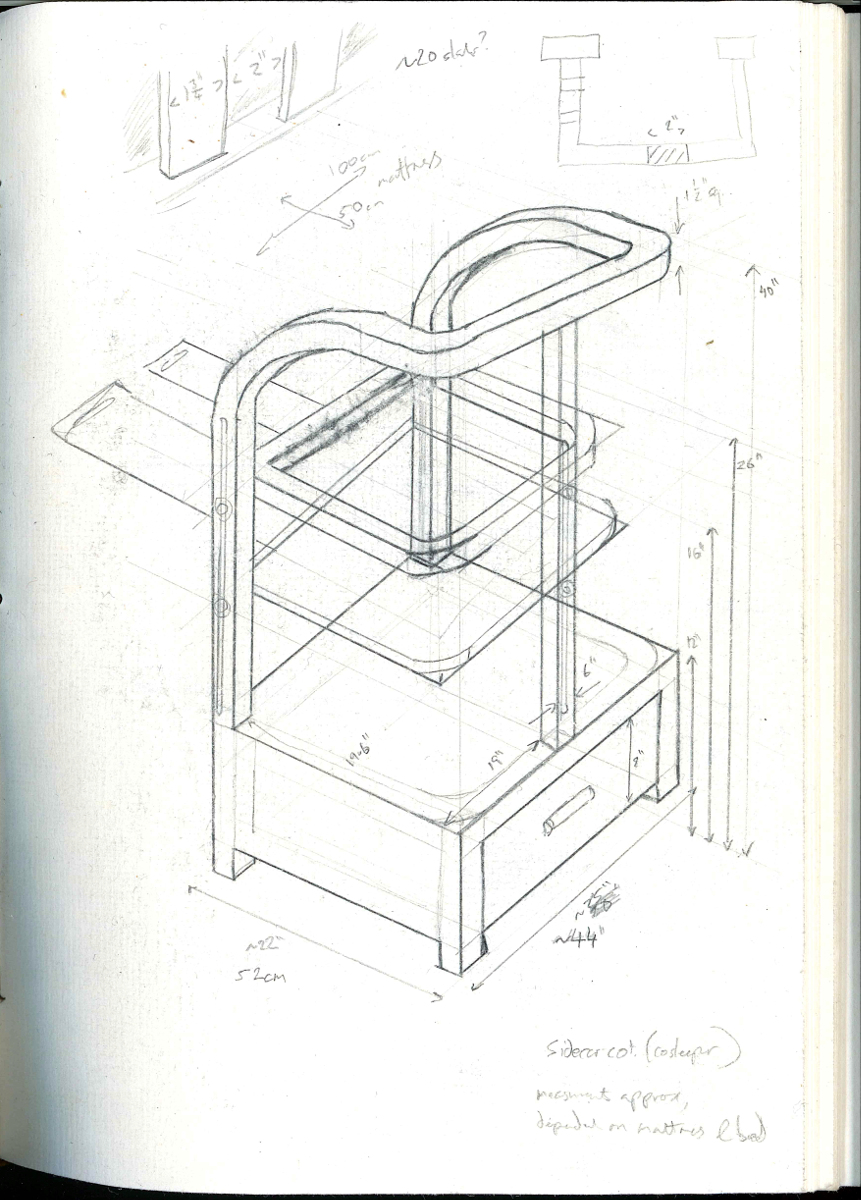

Started off with this idea and this rough-sawn timber:

Insert five months of learning how to do stuff, buying new tools, and at least two months spent learning how to be a bandsaw and a planer thicknesser, and you get this:

Steambent (kiln-dried because I couldn’t find air-dried) walnut for the frame, ash slats and panels, poplar for the drawer sides and slips. Hide glue all round. Fifty-seven hand-cut mortice and tenon joints (one of which wound up in the wrong place and I hadn’t learnt that you could just plug the mortice and recut it). Drawbored some of the frame, wedged tenons for other bits. Dovetailing (through and half-blind) for the drawer. And glue blocks in various places.

All I can see at the moment are the small errors all over the place, but as a first piece, I’m happy with it. Learnt a metric butt-load from Paul’s videos (and some tricks from other places), so just wanted to say thank you to him for making them and passing on the knowledge to everyone.

28 February 2017 at 4:55 pm #309631

28 February 2017 at 4:55 pm #309631That is remarkable for a first piece. How in the world did you attach the slats to the steam-bent side rails?

28 February 2017 at 6:55 pm #309638Mortice and tenon joints with curved tenon shoulders (and straight tenons at a tangent to the curve) Matt. And then lots of fettling to match the curves. The match isn’t perfect though.

Like that, only on the inside of the curved piece. It was fiddly, but it helped that the mortices are only three-sixteenths wide.

Unfortunately, final assembly introduced some twist into the piece and the fit wasn’t as perfect as that in the end (there’s a good 2mm of gap in the worst spot).

28 February 2017 at 7:08 pm #309639Wow, that’s a great job! I’d be interested to know what you’d do differently if you built it again? Also it’d be good to know more about how you did the steam bending?

Rob

28 February 2017 at 7:31 pm #309642I wouldn’t make it so darn complicated 😀

Or so big – the thing is just the wrong side of “this is too big to build in this shed” (I work in an 8’x6′ shed in the garden).And I stole the steambending-in-a-bag idea from here: https://www.youtube.com/watch?v=50uXPPt8-VI

More details on that here : http://www.stochasticgeometry.ie/2016/12/03/properly-bent/

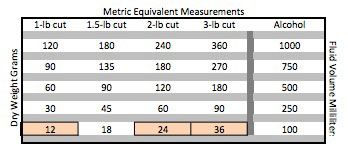

3 March 2017 at 5:09 pm #309769Thank you! The walnut pieces all had had four coats of shellac, sanded back after the second coat as per Paul’s description here; then the cot was assembled and the entire thing had three coats of Osmo thin wood wax. The drawer though just had three coats of shellac over both the walnut and the poplar sides. The shellac was made up as a two-pound cut — only it was a 24 gram cut because I’m a bit metric 😀

So 24g of button shellac from liberon and 80g of isopropyl alcohol (because kitchen digital scales and the tare button make this a lot easier to measure out).

-

AuthorPosts

- You must be logged in to reply to this topic.