Workbench Gallery

Welcome to the Workbench community gallery. You can watch Paul’s introduction to the project here.

Here is Paul’s example…

And now it’s over to you!

Workbench by Matthew Sams

SPF construction lumber, some of it recycled. LVOC oil finish. Along the way I learned how to clean, set up, and sharpen a wide variety of hand tools. Part of the enjoyment has been meeting people along the way and the satisfaction of bringing abandoned tools back into the light. First spatula is now on the kitchen counter…

Workbench by Steve Follis

All lumber was salvaged from shipping crates and pallets. The only cost is the new Eclipse vise, I guess I splurged there a bit.

Workbench by Chas Johnston

Workbench made to Paul’s plans. CLS C16 construction studs used with redwood wallboard. Finished with three coats of Danish oil. My first big project which along with Paul’s videos taught me how to plane properly.

Workbench by Greg Merritt

Built per the version in Paul’s book. Home center lumber and an Eclipse quick release vise.

Workbench by Smudgefish

Following along with Paul’s excellent design and instructions, my ‘forever bench’ is now complete! Been wanting to make it (procrastinating) for four years, since Mrs Smudgefish said I could have the plywood for Fathers day! Wish I had purchased the wood back then, but managed to source some through work. I should not have been surprised but was amazed at every stage just how well it came together. Added the drawer and tool well add on during the initial build, before dismantling and taking home to the garage. Many thanks to Paul and the team, looking forward to my next project.

Workbench by David Gill

Workbench made in july 2011 This was before Paul’s design was available

Workbench by david o’sullivan

pine[red deal] 3 coats danish oil (build from pauls books “working wood 1&2”

Workbench by Orestis

Pine/Spruce, tung oil finish

Workbench by Phill Abram

My new ‘lifetime bench’ for my new garage workshop. Timber from local builders merchant here in UK. Will add the drawer customisation next. It’s not perfect, but it’s mine and I made it! Thanks Paul for the design and the instruction.

Workbench by colin reynolds

yellow birch and laminated softwood 2×6. live edge aprons

Workbench Customisation by Paul M

I finally got around to putting a drawer into my workbench. The main part of the drawer front is the timber from the cut out in the apron (Oregon) and the border is made from offcuts of dark maple to flesh out what was lost during cut out process. The drawer itself is dovetailed pine with ply dividers, and the slides are 600 mm push to open slides. i chose this type of drawer slide in order to keep the face of the apron flat. Finished with shellac, and canuba and bees wax applied with steel wool. #woodworkingmasterclasses

Workbench by Gregor Wagner

I used regular pine. It took me actually a couple of month to complete, and I dodn’t stick to the plans 100%. But it is really sturdy, and fits my small garage. Thanks Paul.

Workbench by larry Goltz

Salted sycamore, from trees i cut and slabbed

Workbench by Zachary N Segovia

Going on about 4 years of use (as of upload, avg. ~10 – 15 hours / weekends) and plentiful wood projects, this humble Sellers workbench is still serving strong. All construction techniques were used from both workbench video series using constructions lumber and boiled linseed oil finish. Someday I intend to expand on this Sellers / English workbench to somehow make an even more personalized and efficient workspace. My many thanks to all at team Sellers.

Workbench by Rob Franz

All the tools used in building this SYP bench including my grandfather’s plough plane and #78 rabbet plane, and my father-in-law’s Disston saw. All others were purchased used and refurbished. Yes I used the cordless drill and screwdriver…and the barely pictured ‘53 ShopSmith, but only for the long rip cuts. Truly a case of the journey being far more important than the destination! Thank you for your fantastic and limitless help, Paul!!

Workbench by Tobias Bauer

my workbench (Paul Sellers’ design) in spruce – build with hand-tools only, seated in my only woodworking space: a small Loggia. (Drawer and sharpening holder have been added after this foto was taken.) I find it perfect in every way – thank you Paul + team!

Workbench by Lisa Burt

Paul’s ‘Hybrid Workbench’: Made the base from pine with mortise & tenon joinery, but loved the look and strength of the laminated plywood bench top so I combined them. Added a dovetailed Sapele & pine drawer (my very first!) The new 10″ Eclipse vise was worth every penny. I’m in love with my workbench. Couldn’t have done it without Paul!

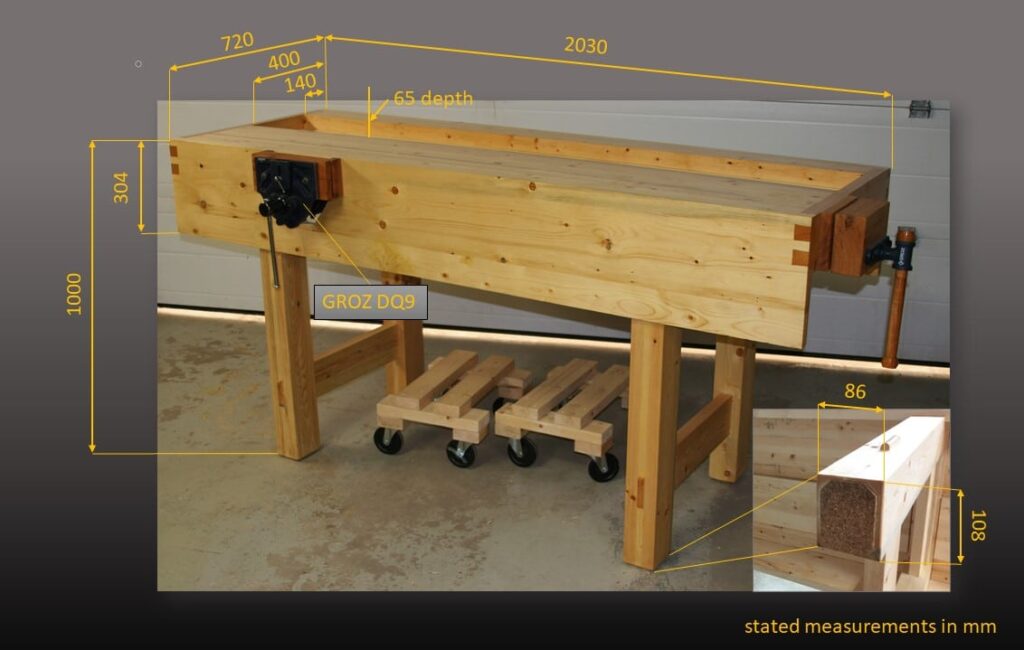

Workbench by Mark Eaden

Finished at last! The ‘white-wood’ is reclaimed scaffold boards (probably spruce), planed true and laminated. The front apron is (very) hard wood from three and a half feet of reclaimed kitchen worktop, ripped, spliced and re-laminated (you can probably see the join). New vice (could not find one used at any price!) with oak jaws, again reclaimed. Castors to raise the bench from the damp floor and wheel outside when the weather is fine… Only the long cuts used power tools, otherwise everything else using hand tools – thank you Paul, it has been great fun!

Workbench by Wouter Engels

40″ tall – Plywood workbench – handtools only. I really liked the look of the plywood workbench, so I decided to build it using my saw. It probably needed a lot more plyning than Paul’s but my sawing has improved a lot.

Workbench by John King

Here in New Zealand another Sellers bench is born from timber from part of my house and othe bits mostly found. This is the start of my retirement at 68. It’s not perfect but I feel very happy with the end result.

Workbench by Christian Kayser

I made the workbench from regular construction timber and pretty much exactly from the drawings. The jaw liners on the vice are made from oak scraps from the building site where I work.

Workbench by Jim

Paul’s design with dog holes

Workbench by James Taylor

workbench using Paul’s design and instruction

Workbench by robdavies

7 foot workbench. Made with Redwood and a simple shelf underneath. Top is 4 inches thick so it’s nice and heavy

Workbench by Suko Rahadi

Bangku kerja ini saya bangun dengan material kayu mahoni. Ukuran bangku 200 x 90 cm. Menggunakan sambungan sebisanya dan alat seadanya. Semua serba manual dengan hand tolls. Belum punya power tolls.😁

I built this work bench with mahogany wood material. Bench size 200 x 90 cm. Use whatever connections and tools you can. Everything is completely manual with hand tolls. Don’t have power tolls.

Workbench by Leslie

Oak aprons and top, cherry tool well, used up material that had been stored for years in our old dairy barn. I love this table over my Roubo.

Workbench by Ben Fricke

Work bench built with 2x4s and 2x12s from the hardware store. The legs are built from reclaimed lumber off a 1948 IH grain truck in my back yard.

Workbench by Anthony Kaye

Slightly modified workbench

Workbench by Philipp Klinkhardt

Workbench by Philipp K. Built with construction lumber. Drawer and additional well are on the way.

Workbench by Michael Nevin

Workbench Drawer by Bryan Donovan

Workbench drawer. I messed up the measurement for the half-blind dovetails so I had to go with through dovetails — and then I plowed grooves through the wrong. I just plugged the holes and pretended it’s supposed to be that way.

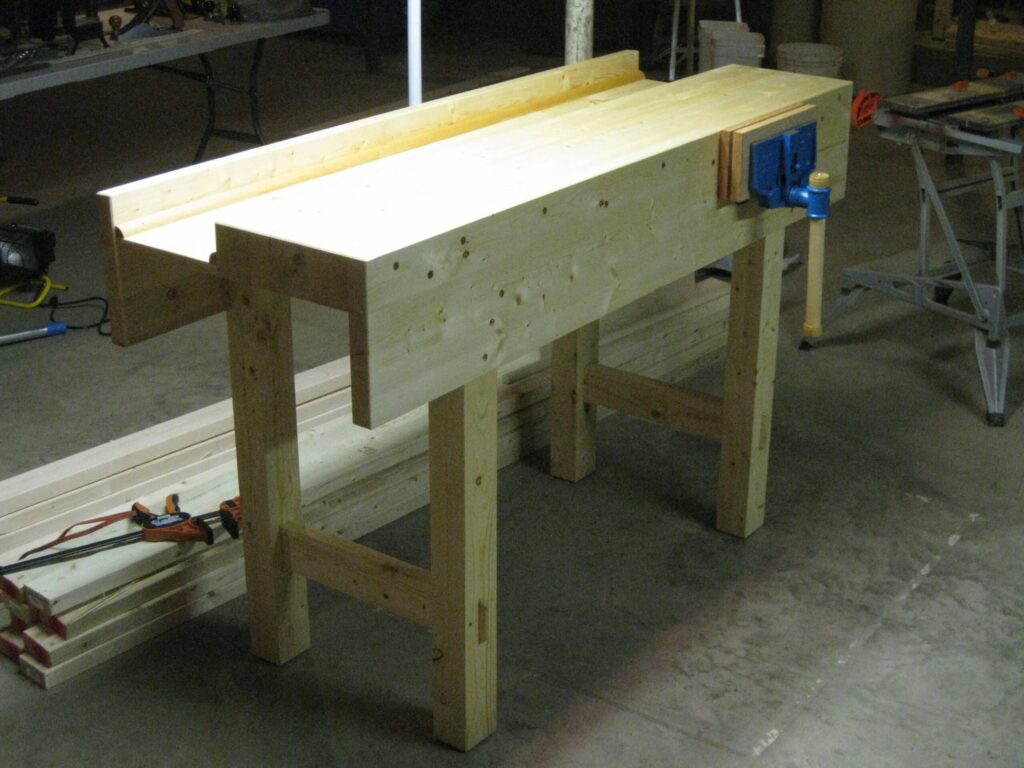

Workbench by Bryan Donovan

Workbench I made in June-July 2020. First project other than a dovetail box and a wall shelf.

Workbench by davisjm

Workbench made from construction grade lumber. Base is painted and the top is finished with boiled linseed oil.

Workbench by Jason Jenkins

Pine and Douglas fir with danish oil finish

Workbench by Nick van Beest

Small workbench (86 cm wide, 61 cm deep, 100 cm high, or 34″ x 24″ x 39.5″) for a small workshed (2.7 m x 1.8 m), inspired by the Paul Sellers bench… Used pine for the frame and the tool tray, beech for the top and apron, and oak jaws for the vice

Workbench by Victor Wang

72″ W x 28″ D x 38″ H. Has a 19″ work surface and 8″ tool well. The aprons are 13″ tall. Made entirely out of vertical grain Douglas Fir (except Sapele for the vise liners) . The top, legs, and rails, and tool well are made of laminated 2x4s. The aprons are laminated 2x6s and 2x2s. The 2x2s were added when I realized the aprons weren’t long enough to take the bolts. Finished with Tried and True Danish Oil. Made entirely with hand tools.

Workbench by novicejon

Fir legs and top, everything else is spruce and all the tools used to build it

Workbench by Pjotr Bos

My second project after the three-legged stool. Partly made out of recycled pinewood. Its in my living room attached to a wall and the legs rest on a plank screwed to the floor for more stability because of the flexing wooden floor.

Workbench by Jim Carr

My version of Paul’s work bench. Made from box store bought Southern yellow Pine. Raised a little to accommodate my height and used 5/4 material for the bottom of the well to give me a little bit deeper well. Otherwise copied Paul’s to the best of my ability. The trellis wedge stabilizers are absolutely amazing. Purchased the same vase as Paul’s online and finished it with Linseed oil. Love it. Thanks so much.

Workbench by Pantelis

Workbench by Dale Beatty

My workbench

Workbench by Alexander Okada

My first ever Workbench!

Workbench by Yves Gaudreau

Made from twisted white Birch cut here in Denholm Québec in 2003. Finished with “Tried & True Varnish oil”. None of the 8/4 by 8 feet long boards were straight enough to give 66 inches long boards. Even the boards for the aprons have been backed up with reclaimed yellow birch from some old kitchen cabinets. I laminated 24 to 34 inches long pieces to make the top and the well board. Great adventure, very pleased with the result. The hand planning of the top has been challenging with the grain changing direction every other board. But with the good advice from Paul on hand planing and sharpening (now I sharpen free hand 😀 ) have made the exercise possible for me. Thanks Paul!

Workbench by Dennis Droege

Ash workbench from a tree our arboricultural service removed. Record vises from Ebay.

Workbench by GreggE

Workbench built with all with framing lumber. Secondary usage: Quarantine home office 🙂

Workbench by mark leatherland

This is my workbench, there are many like it but this one is mine. Paul was right… I could do it and I’m very pleased with it and proud to have achieved this as a beginner with newly aquired hand tools. Bench height is 41″ which feels perfect for me. I’m 6’3. Vice is a 1930’s record 52 1/2 from ebay. Paid £82 – Still works perfectly. The benchtop and legs and wellboard are redwood pine, the aprons and rails white pine. Redwood was much nicer to plane

Workbench by David Fernhed

168 cm wide, 106 cm high. My first project with handtools. Constructionlumber from my house

Workbench by PaulM

I chose to use repurposed Oregan (Douglas Fir) for the majority of the build. in order to obtain the desired width dovetails and aprons, 19 mm Tasmaian Oak was added. this also provides a hard edge at the most vulnerable areas. The Well board is constructed from Cypress Pine floor boards that I already had. The finish is one coat of shellac and two of satin polyurethane.

Workbench by Michael George

Paul Sellers style workbench w/ flush mounted Milwaukee vise, Roubo style planing stop & holdfasts. Poplar benchtop w/ Walnut, Hickory & Red Oak. Douglas fir legframes. 62″L x 28 ¹/⁴”W x 38 ¹/²”H

Workbench by steven newman

Made almost 7 years ago, from wood found in the dumpsters. An old waterbed frame supplied most of the pine parts, Legvise is a 8/4 Sycamore slab, using a pipe clamp. A $10 Craftsman vise sits at the end, and an Oak Crochet at the other..Bench has evolved over the years…Added the cabinet and a shelf a few years ago. Seems to do just about every job I need it to do.

Workbench by Wim Leplae

Pine workbench with extra tail vise, dog holes and tool tray. Finished with anti-slip clear parquet oil.

Workbench by Don Nelson

Build from reclaimed Douglas Fir floor joists.

Workbench by Erwin van Dijk

Workbench by Stephen Tyrrell

My workbench, a hybrid version from both of the work bench series, mainly because I mucked up the first bench top but didn’t want to throw it away.Made entirely from radiata pine stud timber, which meant laminating the legs and the apron. Huge learning curve but enormous fun. This photo was taken about six months after I finished it. I have added the shelf for the shrpening plates (not visible from this angle), a storage shelf and casters.

Workbench by Roland

The workbench is made from construction timber (38×89 mm). The dark parts are burned, brushed and finished with some leftover black floor oil. For the rest I used linseed oil. Making de bench was a great experience! Roland, The Netherlands

Workbench by David Vergona

SPF pine,9″ eclipse vice. Took 1 month to build using borrowed record #4, 2nd hand free saws, and irwin marples new chisels. Built the saw trestle first then this bench. Best thing i ever did. Its been just over a year since i did this and have been real woodworking since. Thanks Paul and crew.

Workbench by Brian Rosenberg

Finally got around to building my first workbench. Used left over lumber from a remodel over the summer months. It took about 3 weeks of nights and weekends. Based on Paul’s workbench with a few modifications. The major changes I made here in the legs because of the lumber I had on hand. I also increased the width of the top to 16”. Honesty glad I waited a few years to attempt as my skills have grown since watching Paul build that bench in his backyard. Thanks again.

Workbench by William F

I built this from the old old YouTube series! Due to two moves over 4000 miles, I finally completed it! Made of standard 2×4 SPF

Workbench by Ton van Schaik

Completely made of rough sawn pine beams (2 x 3”). There is one on the bench.

Workbench by gerard van Heel

Loved every minute of building. Glued up from my dad’s warped and crooked pine floorboards. Lot’s of handplaning. Thanks for all the input Paul Sellers!

Workbench by Wouter Naessens

My mostly finished workbench, 6ft 9 1/2 inches long, built from SLS construction wood. Inspired by both Paul’s and Richard Maguire’s takes on the english workbench. Still needs some BLO finish, planing stop board running down the middle and I intend to use holdfasts as I will need to work on bigger pieces, which I’m not too comfortable with holding in just the vice. So there will be a small number of holes in the worktops and the back apron as well.

Workbench by Raphaël P

What a journey!

Workbench by Dave Alvarez

My copy of Paul’s plywood workbench. Its identical to his plans with the exception of 1) a solid pine (2 x 4) top and 2) through, wedged dovetailed horizontal pieces on the leg frames, without his extensions on the ends. Othewise, all 3/4 birch plywood construction, with a 10″ Yost vice and casters.

Workbench by DAVID CROZIER

My first Paul Seller’s project. Really enjoyed making this.

Workbench by Mike

5′ 6″ long, 24″ wide (31 1/2″ with the tool tray) 36 3/4″ tall. Top and frame; douglas fir, well and aprons; southern yellow pine, tool tray; white pine. The H frames have been stained with vinegar and iron. Boiled linseed oil finish.

Workbench by Ivar

Made from pine. The material for the top I bought from a window factory. Really dense and one side without knots. It is in my garden shed, so there is a lot unrelated to woodworking. Will make shelves on the wall for tool storage.

Workbench by Simon Baker

My first woodworking project. Made using recycled wood from https://www.bwrp.org.uk/. Had to restore two hand planes before I could start and of course learn how to sharpen up! Still learning… but none of this would have been possible without Paul’s generosity.

Plywood Workbench by Justin Schafer

Workbench by Gleb Dmitriev

Workbench from construction grade pine. I added a tool rack to the back apron. It helps to keep everything in order and close at hand.

Workbench by Jonathan Brandon

Workbench by Christian Unmack

Pine finished with Osmo.

Workbench by BTC

European Redwood & CLS with Ash jaw liners. Record 53 Vice. Made many mistakes but a great learning experience and solid as a rock, ready to go make! Thanks so much Paul & Team!!

Workbench by Giacomo Zanon

I made it 🙂

Workbench by James Fisher

Largely made from lumber salvaged from discarded fixtures, which were covered in grey paint, from my employer. The wellboard is of ash from one of the fifteen trees cut down in my yard that were killed by the emerald ash borer beetle. You can see stacks of the lumber drying in the background of the photo.

Workbench by Rob Flores

Douglas fir studs with laminated 2×4 legs and 8″ rails. First bench, first time woodworking, first time using hand tools. Thank you Paul.

Workbench by Corné Gelderblom

plywood workbench

Workbench by Tim Gulliver

Reclaimed Australian Hardwoods, inc. Spotted Gum, Southern Silky Oak, Australian Red Mahogany and Merbau

Workbench by Tomlawrence

Reclaimed Pine workbench

Workbench by Dai Pritchard

Made out of 4×4 and 3×3 fence posts and some reclaimed construction timber. My first project! so nothing truly square. End product plays homage to Chesterfield Spire!

Workbench by Tom Heikkinen

Spruce top, Western red cedar legs w/ Douglas Fir stretchers. Aprons are laminated veneer lumber, tool tray is cedar.

Workbench by Shed

Paul style bench. Box store pine. Sturdiest thing I’ve built.

Workbench by Kevin moss

My new workbench

Workbench by Mark Ridley

Cherry / mystery hardwood / spruce striped bench – including a planing stop made from one of the cherry strips

Workbench by Karol

Made of spruce and as per the istructions, ended up with oversized and overweight apprentice piece. Took me twelve months 🙁 still very happy with the result…

Workbench by Scott Carro

I built this child sized workbench to teach woodworking to children. Made from Cedar and Pine.

Workbench by Rod Brink

Sellers work bench modified smaller with accessories

Workbench by jblakley89

Douglas fir with a 20″ top and 4×4 leg assemblies

Workbench by Daniel Willis

I used regular lumber yard SPF for my build. The legs were laminated of 2×4 to get square legs once planed to size. The aprons might be a bit narrower than Paul’s but they work. There’s a drawer that I finished just the other day. Hand cut dovetails in the drawer, loose fitting compared to others but they work. And they’ll get better with time. The drawer handle is big and beefy. I like it that way. Feels heavy and solid in the hand. It came from a piece of maple the tow truck driver left behind when he hauled away the container when we moved here last summer. Red leather for the vise jaws came from a cow hide I purchased while deployed. A port visit to Souda Bay and a little leather shop in a back alley. My strop is also made from that cow. The bench has the sharpening shelves on the left size but no tool well in the back. Yet, that may come. Until then, I’m going to have fun building boat parts at this bench. Thanks Paul and team.

Workbench by Gordon Tipene

Workbench in pine. Solid! Great project to learn basics. Thank you Paul.

Workbench by Benjamin Caton

Paul’s workbench design, made from $36 in reclaimed old pine lumber from old Portland homes.

Workbench by Einar Tveter

Used some X-mas holidays to build a new workbench of pine. A real “Paul Sellers” design. I am happy with it.

Workbench by Alex

After much contemplation I finally got it done. Benchtop is vertical grain doug fir. Wellboard is pine. The rest of the bench is kiln-dried construction grade douglas fir. I still need to add the jaw liners and apply a finish but its mostly done.

Workbench by floren

Workbench Customization – Drawer

Workbench by Giorgio

Workbench in fir finished with oil

Workbench by Chris Harglerode

Laminated 2×3 for top and aprons, 4×4 and 2×6 for the legs, laminated 1×6 for the well board, and 3/4 pine for drawers.

Workbench by Scott

Workbench out of pine and something else…

Workbench by Keith Oxby

I made the new workbench and followed the design fairly closely. Made of SPF 2x4s and some eastern white pine for the aprons. It took so long to prepare all of the lumber with a handplane, but once that was done the bench came together fairly quickly. I love it!

Workbench by Tim Reuter

Thank you, Paul Sellers, for all your instructions and guidance. Your: “You can do it.” was helping me lot. My bench was made as a hybrid design of your garden and indoor project including a few ideas along the way. The bench is made out of standard construction SPF, 2 by 4’s (top) and 2(1) by 6’s (laminated legs). Aprons, legs and top are glue together permanently using PL400 instead of wood glue to allow for a bit more flexibility. After assembly, the workbench felt somewhat odd standing on my concrete floor, so I glued disks of cork onto the legs which gives the bench a “softer” feel. Bench is finish with Tung Oil and 3 coats of varnish. For the front vise, I recycled my oak kitchen cutting board, which interestingly revealed after plaining a very smooth texture likely from being “soaked” for many years with fat and oils. For the end vice I laminated 1-inch red oak. Thank you, Paul, for sharing so many great lessons and plans! Tim Reuter, Canada

Workbench Drawer by btyreman

Workbench Drawer, made from redwood pine, the only part I changed was to use a double tenon instead of wedged tenon on the back piece, the bottom is made from solid sapele, it gets used a lot.

Workbench by Hassan M.

Here’s my workbench. I made it from pine, finished it with polyurethane. It’s really nice to finally have a solid workbench!

Workbench by Rick Wallin

Work Bench, eight foot long with tusked through tenon suspension and 2×12 for tool well.

Workbench by Urban Englund

My new Workbench made from spruce wood.

Workbench by David Sims

Poplar and Red Oak

Workbench by Nenad Jankovic

Recycled wood (oak for top and legs, pine for other parts)

Workbench by Mike Field

Here it is! Clear redwood with Boiled Linseed Oil as the finish. Just a few more customizations and its completely finished.

Workbench by Andrew Konopitski

KD Doug fir and white pine. Had to change the vice location because I bought a 10″ QR vice, but didn’t account for the size in the plans. Very happy with it so far. Been watching the videos for years. Thanks for all the instruction Paul and team

Workbench by V M

Small but study workbench made out of pine

Workbench by Paul Rowell

Just retired and have wanted to do woodworking for a long time…

Workbench Drawer by beach512

Workbench Drawer made of pine. All done with hand tools. Blind dovetails and housing dado with wedged through mortise like Paul showed in the 5 episode series.

Workbench by Øyvind Akselsen

The project was finsihed in norwegian sprouce, with elm for the vices

Workbench by David Boyle

My first ever joinery project! My late father in law who I never had the pleasure of meeting had been a keen woodworker. I had noticed a plane in his garage a couple of years ago and hadn’t known what it was. It turned out to be a rusty no4 record. In researching the plane and how to restore I happened upon Paul’s YouTube channel which is an invaluable resource. I restored the plane and built the bench to begin to learn its use and maintenance. I know my bench isn’t the finest example but it’s solid and heavy and feels fantastic to use. The vise is a heavy brute of a thing that I saved from our previous house, a Parkinson, also restored and working well. I really like the idea of continuing to use old and once forgotten tools and in a sense bringing them back to life. I sometimes think of the people that used them previously. Thanks for this amazing resource and the opportunity to think about the past and learn new and valuable skills

Workbench by Oscar Visser

Workbench, just for myself

Workbench by Steve

Made from pine from a local sawmill. Included my dad’s old Record 53 – also in picture is joiners mallet . dogs and winding sticks. Many mistakes but have learned a lot.

Workbenches by William Thompson

Used fir 2×4’s from Home Depot and an old twisted 4×4 for the legs. Made the 4 year old and 2 year old grandson’s bench from left over material.

Workbench by Michal Vrabel

I spent a lot of time, when I bought all tools, but thanks to the Paul I could do it and I built my first workbench. I used a Spruce, vice – YORK – HVRQ802 9“, finish – hard impregnating nature oil. Thank you for your help in this matter. Best regards, Michal from Slovakia.

Workbench by Mike Lee

Boxing grade pine with recycled treated pine legs

Workbench by Richard Burton

Workbench made pine 4×2’s. Took a long time to build but sure beats working on a wobbly black and decker workmate! Was a great learning experience and really enjoyed the build.

Workbench by jrmacias

My take on the workbench…

Workbench by Gregory Chambers

Reclaimed tobacco barn poplar from western North Carolina. Tung oil finish.

Workbench by Andrea Mazzini

My first woodworking project had to be Paul’s workbench. Built from spruce, hand tools only, and a 9″ Record vise.

Workbench by Augusto Campos

AugCampos Workbench, wood spruce and osb

Workbench by zjonak

Yet another workbench

Workbench by Reagan Herman

My new workbench

Workbench by Jonathan Ard

Pine from Lowe’s. Made mine a little less wide and deep to better fit my space.

Workbench by Mr Teroo

Workbench by Stephen Marchesani

Started with roughsawn old lumber infested with powder post beetles. Took 3+ months of nights and weekends. I have never been prouder of a singular achievement. Only used the tools on the bench. Thank you, Mr. Sellers.

Workbench by Zdenko Tudor

Spruce

Workbench by Charlie V.

Paul’s workbench plus a set of drawers

Workbench by Sandy

Basic Workbench of Pine and a Wilton Quick Release

Workbench by Jac Norton

Mini work bench. Leg frames in Jarrah (recycled house frame), benchtop in Tasmanian Oak (found in dumpster at worksite) apron in Redgum.

Workbench by Andy Karmy

Here’s my version of Paul’s latest design. I stayed true to the design, used as much salvage fir as I could for the top from an old storage shed. The bench turned out great and I had a fun time following along the videos.

Workbench by Paul Bowes

My new Workbench made from 2×4 and 2×6 stud grade lumber. Not the clearest but with some work it planed up well. Glued the leg frames and wedges as I do not intend to break it down. Finished with shellac mainly as a sealer as I am in a high humidity area and wanted to help make the wood stable. Rubbed with very worn 240 sand paper, and finished with 0000wire wool and wax.

Workbench by Stephen Hillier

Built mainly from Scandanavian redwood this bench is 71″ long. It started life as an unadulterated Paul Sellers design but then changed a little. I was pursuaded by other designs I saw that having the legs in the same plane as the worktop was an advantage. I added a front stretcher (it has no structural use) and some fillets to fit to the front of the legs. The shelf underneath is what remains of my old workbench recessed and fitted over the side stretchers which does add some strength. I have used a 9″ Axminster vice recessed into the front apron. I have yet to fit a liner to the front jaw on the vice. Plans include fitting a full width twin screw tail vice. On top of the bench are a couple of mallets and a small round hand plane that I have made..

Workbench by Mikael Arvola

Made from cheap Home Depot douglas fir 2x4s, with the exception of the vise that’s cherry. The legs on the end with the vise are a bit further from the end for clearance (14″), and the well is only 9.5″ wide, but otherwise pretty much exactly like the older YouTube videos.

Workbench by Greg Marshall

The top, aprons, and wellboard are southern yellow pine that I had in rough sawn 10/4 stock. The rest is kiln dried construction lumber from Home Depot. I’m quite tall, so the benchtop stands 41″ high and is 4.5″ thick. The joinery in the leg frames is far from perfect. This is my first piece of “furniture” and the first thing I have made larger than a dovetailed box. When I get the face vise mounted, I’ll be done. I am so excited! I love this bench, warts and all! I can’t wait to start using it!

Workbench by Glenn Kuffel

I’m a retired Sailor. My first workbench. Never used a hand plane or chisel before. Thank you Paul and team!!

Workbench by Rodney Worthington

My lifetime bench. Pine, maple wellboard, treated pine legs(not my first choice).

Workbench by Emmanuel Olive

Small workbench in oak with walnut dowels.

Workbench by charmston

Another workbench that works…

Workbench by Raleigh Holtam

Workbench built under the instruction of Paul’s original “garden” workbench videos. Yellow pine construction.

Workbench by David Berry

Pine, roughly 72″ x 26″ x 37″ (I’m 5’6″). Lower is milk paint, with Boiled Linseed Oil overall. Followed the “Working Wood” workbench, which is very similar to the new videos. Most of the tools are restored from old — Stanley planes and Disston Saws (the one closest to the vice was found in an antique store for $3, freshly sharpened — I haven’t restored it but used it throughout the bench build.

Workbench by ejorg17

Just finished the workbench based on Paul’s design! 5 feet long by 27 inches wide by 38 inches tall, made from western spruce with Veritas quick-release vise with plywood liner.

Workbench Ian Hemphill

Thank you Paul! I still can’t believe I actually made this with hand tools – it is an outstanding working space and solid as a rock. Standard construction SPF 2 by 4’s. The vise is a Yost 9” from Amazon.ca and I managed to get it on sale at less than half price ($90 Canadian). Excellent value and a great vise. Now I’ve got sharp tools and a great bench – onward to learning more joinery. Thank you so much.

Workbench by Paul Rowe

Made from rough sawn pine, hand planed and adapted to suit workspace 60″x29″ with dovetailed draws for storage.

Workbench by Bill Hall

Used 2X4’s from the local big box store. Bench is 33”w X 78”l X 39”h. Finished with a walnut stain and several coats of shellac. Added quick release vise. Inspired from Paul’s 11 part YouTube video series from 4 years ago. Can’t say enough about how great of an experience it was to hand chop the mortise holes as well as using a hand plane. You really do get a feel for how will respond and when to plane in a different direction depending on the resistance you feel. I wish I took that into consideration more before I glued everything up as a group….at least I think it may have helped some.

Workbench by Zeppos

Workbench 230cm wide, 73cm deep, 99cm high

Workbench by André

Workbench: made from dimensional SPF, 65cm x 150cm, 97cm high. Finish: two coats of shellac, wax. Eclipse 9″ QR vise with red oak pads. — This was my first big project. It took me two months of weekends to make. Hand planing round corners of knotty two-by-fours was painful but valuable experience. I had to sharpen my plane every half an hour. Squaring the aprons was time consuming: I had to rebuilt them three times because they kept twisting overnight. I can safely say I learned a lot while building this bench by using hand tools only. Despite all mistakes and imperfections, I’m happy now. — When you make your project, remember: Never give up.

Workbench by Kurt Schultz

8’ x 3’ bench made of 2 x 4 Euro spruce that needed much trueing. Built to spec (Paul’s bench videos). Top is finished with English walnut stain and spar varnish, well and legs finished with grey satin paint and waxed. Took me about 40 hours to build. Outfitted with a quick release front vice – Massey Patent No. 17 and a bench stop (both were yard sale freebies) End vice is a paid for new Wilton QR vice. At over a 100years old, the Massey outperforms the Wilton in both form and function. Bench lifts installed on legs to mobilize as needed.

Workbench by tcurtis

My first real woodworking workbench, made from box store Douglas Fir. This has been a great learning experience.

Workbench by david k

Mabe with all materials found around my farm. No glue is used. I did connect the top with all thread and nuts. The entire project can be taken apart and moved very easily. All the wood came from the local lumberyard. It is either number to Pine or in some cases pressure-treated yellow Pine.

Workbench by Leland Purvis

Douglas Fir, Pacific Northwest. Mostly salvaged/reclaimed wood from a 100 year old barn. (Some hidden nails and screws ravaged my plane irons, though!) Passed on the lams for the top and went with a solid beam. 6’6” x 30” x 38”. End vise is a new Eclipse. Face vise is a Record 52 1/2, off of ebay.

Workbench by rickyli647

Joinery bench made out of construction grade pine. 2′ wide and 4′ long, with a tool slot at the back. top glued up in two slabs, however, the wood is not dry enough, warped a bit, result in a gap along the center line. used bowtie to stop the gap from getting bigger. bench top is 39 inches high, bring the work piece closer to the eyes for joinery. may eventually replace the front vise with a moxon vise.

Workbench by Kyle P.

I followed the video/blog series to make my workbench out of the infamous “white wood,” which I bought at two different times and got two different woods (i think spruce and doug fir). I got a good workout planing down the rounded edges throughout the project. My well board ended up short in width, but that ended up being a perfect slot for my chisels/saws/etc. I took the picture after working on a couple projects, so it’s a little dinged up. Great learning experience!

Workbench by HR

4ft Workbench Southern Yellow Pine

Workbench by Vic Lewis

This is my first project and my take on Paul’s European workbench, made from construction timber bought from the local B&Q store. Next to make is some of Paul’s accessories ie shooting board and little jigs.

Workbench by Donley

My first big build. 2×4 pine. 5 foot length with each bench being 13 inches wide. The well is 12 inches and the aprons are 10 inches.

Workbench by Arthur Coates

7′ 9″ pine bench with a coat of amber shellac

Workbench by baladd

2×4 studs fir thanks for great instructions

Workbench by rajavikrama

Workbench using White Sal – 2 feet by 6 feet – Spray Painted

Workbench by btyreman

Workbench after 6 months use, it has been rock solid! made with redwood pine.

Workbench by kenhamilton

My workbench when it was a baby… Just 2×4 studs…… strong sturdy.. It now has a vise.

Workbench by civilenginerd

Made from Home Depot 2×4’s coat of boiled linseed oil. Vise jaws made from ash

Workbench by tobiasbilger

I simply built the bench Paul Sellers showed in the videos. For the tabletop i used spruce/fir 8cm by 8cm. The aprons and wellboard are same wood but 4cm by 8cm. The bench is 220cm long. For the legs i used 10cm by 10cm spruce/fir. The bench is also mobile as Paul’s is, just 12 screws hold it together. My working height is 103 cm as I am 183cm tall.

Workbench by paulhuss

Made from Spruce. Note if you want to use Holdfast you better choose Hardwood for the Benchtop.

Workbench by dusty32309

Drawers and shelves added

Workbench by christo826

3′ x 7′ Work Bench finished with BLO This was right of passage for my Woodworking Future, The Beginning!

Workbench by texaspartsman

My son wanted a workbench for Christmas – Santa was more than happy to build one.

Workbench by Nick Puiia

6′ bench built from yellow pine reclaimed from an 1880’s textile mile

Workbench by Christopher Guest

63 1/2” long, 29” wide, 38” high. My first hand-planing, real woodwork project, following Paul’s blog and youtube videos. Started with rough-sawn unspecified softwood timber. Learned so much along the way, mistakes and all: it took weeks, but now finally having a solid base is really something. As well as Stanley #4’s used old wooden jack and trying planes bought on eBay in a job lot of a carpenter’s tools, with the names of previous owners stamped on them. Another very lucky purchase was the Record 52 1/2 vice which I restored. Sapele linings for the vice jaws, oak wedges for the leg frame housings: an introduction to the qualities of different woods.

Workbench by greitzera

Pine Workbench with Record Vise

Workbench by moody2585

My very first project. 5ft version made entirely with hand tools! Used cls 2×4’s and an old Paramo No.51 vice, with beechwood jaws. how easy Paul sellers makes this look in his videos only serves as a testament to true master of his craft , an inspiration to all us would-be wood workers. thanks for all the great lessons, can’t wait to get started on the next project!

Workbench by Augusto Campos

AugCampos Workbench 02

Workbench by gregglendy

Workbench made from pine. Finished with dye, shellac, and an oil based glaze.

Workbench by markdennehy

Slightly tweaked version of Paul’s bench, built to fit inside an 8×6 shed. Horrible quality scabby whitewood pine, Record 53A face vice, Veritas inset end vice, Gramacy holdfasts and Record 169 planing stop holder.

Workbench by Matthew Chapman

Sellers style workbench in pine. Matthew Chapman.

Workbench by jmeir248

Douglas Fir, Left Handed. Added a leg vise after this pic was taken

Workbench by Dave Robbie

Common construction grade wood found at Lowes. Followed plans from Paul’s Working Wood 1&2 Artisan Course book. Eclipse vise.

Workbench by Todd Corbin

My grandson asked if we could build a work bench just for him. Made from spruce construction grade lumber. The plane he is holding is his. It is a Sargent number three size. He loves it. Thank you Paul another generation you are inspiring.

Workbench by timvogen

I made a 4’x8′ bench at my work. Came out really nice. Used all reclaimed 2x doug fir material just collecting dust at work. The wood has been laying around for years so it should be real stable. Finished with leftover spar varnish. Jorgensen 10″ vise.

Workbench by Vincent Loschiavo

6’x25″x39″ – Douglas Fir – Other than milling off the rounded corners of the 2x4s with a table saw, the entire project was built by hand based on Paul Sellers’ fine tutelage (book, blog posts, and videos). This was my first project built with hand tools and I have a great sense of accomplishment. I may finish with danish oil, but I think it looks (and works) great! The vise is the 9″ quick release steel vise from lee valley, made in the Czech republic. The vise jaws are lined with 11″ x 3/4 maple.

Workbench by timvogan

i used 2×3 doug fir for the top laminates and a 2×12 of the apron.

Workbench by rtexacwby

Combination workbench, assembly table and table saw out feed.

Workbench by MIsha

A shorter version.

Workbench by valeriodangelo

Fir heavy duty workbench

Workbench by manuel42

My first real woodworking project with hand tools. Far from perfect, but I’m happy. It took me about 10 days.

Workbench by mmoreno610

60″ x 28″ x 37″ high, Legs, main top & well are white pine, aprons are douglas fir. Added the wheels for mobility.

Workbench by texaspartsman

Made out of pine from Home Depot. It is rock solid and has improved my wookwooking. It is a great design. It is not completely finished. I plan to add a shelf to the bottom and drawers on the side.

Workbench by Nick Stokes

2×6 Bench

Workbench by Brett Dowden

My first woodworking project and my first bench. Made from Douglas Fir 2×4’s with Red Oak for the vise jaws.

Workbench by Orestes Valella

New workbech, 60″x 24″x 38″ high made from poplar.

Workbench by Aaron C.

My Paul Seller’s work bench right after completing the initial build. Used 2 x 4’s from one of the big box store’s and finished with several coats of danish oil. This was my first real woodworking project since high school (20+ years ago). All hand tools except a drill/driver for pilot holes. Completing it was a huge confidence builder!

Workbench by W

Maple, 47″ long to fit my apartment. I tried using construction pine but got so frustrated I almost quit. Paul’s three-day project took me five months and hundreds of hours of trial and error, but I’m excited about what I’ve got now. On to the next project!

Workbench by David R.

white and blue workbench (5′, 53ED vise, milk-paint, shellac, wax)

Workbench by j.calnan

Salvaged 2×4″s from 1890 red fur,36″x80″ 37 1/4 hieght

Workbench by Nathan Warren

made of “pine” from The Home Depot, 6′ long, exactly 35″ tall and 20″ of workable top space

Workbench by under2x

2×4 doug fir workbench with Milwaukee vise

Workbench by NikonD80

Spruce top with reclaimed timber for the legs and Mahogany vise jaws.

Workbench by Pat Haslam

My first proper project. Made with standard pine from the timber yard using a very wobbly B&D Workmate and a metal working vice bolted to an even more wobbly bench! Old Record vices cost £90 in total, the wood about £120 and fixings/glue £30. Very happy with it, really fun build.

Workbench by Ian Lambert

Douglas Fir/Oak. Paul’s Utube build inspired me to get on with laminating the top.Thanks Paul.Unlike Paul I have always wanted an end vice and dog holes. Time will tell if I like them!

Workbench by Mick Mercer

My work bench

Workbench by Jay

Small bench based on Paul’s design and instructions. 50 in long. Woodriver vise. 3 coats Danish oil.

Workbench by nljsellers

I finally finished it, and have a great sense of satisfaction from getting there, Made loads of mistakes but learned a lot

Workbench by harshdoug

Built entirely out of “mystery” wood 2×4’s from the big box store

Workbench by Srecko Hajdinjak

Whole bench made by 2’x3′ construction pine; of course with “a little help” from my teacher Mr. Paul’s blueprint!

Workbench by Andy Cleland

6 Feet long, 39″ high

Workbench by Richard Fulcher

Pine workbench (5ft x 2.5ft) with second hand Record quick release vice.

Workbench by Mark Seay

This my version of Paul’s workbench. It is constructed of home center 2x4s and the vises are padde with oak. The top is 30×61 and the height is 38 inches which, so far, I find quite comfortable. I also added flip up casters for mobility.

Workbench by Spencer Schwab

Workbench per Paul’s design – 6′ by 2′ with a 37 1/2″ bench height – My trusty companion Beau

Workbench by Gareth Mann

Pine wood bench

Workbench by Brandon Avakian

Paul Sellers Workbench – 5′ Long Version

Workbench by david o’sullivan

pine[red deal] 3 coats danish oil (build from pauls books “working wood 1&2”

Thank you to everyone who has sent a picture in!

If you would like to submit a picture to the gallery, please use the submissions form.