Workbench

This is the introduction for a free series. Want to watch the whole thing? It is free to do so, you just need to log into the site, and you can enjoy this series and many other videos we think you will love.

Description

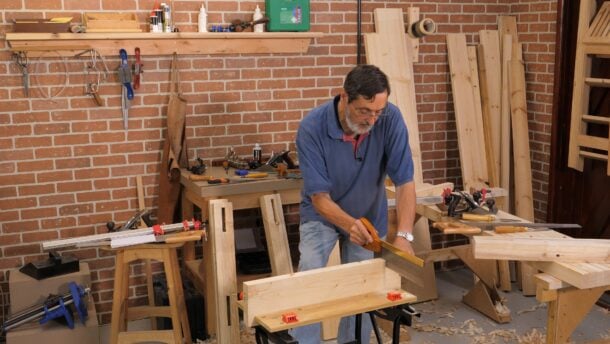

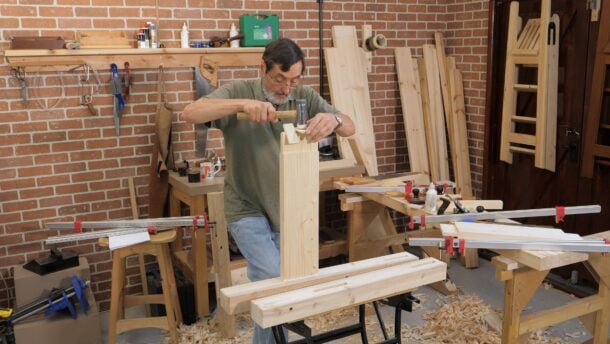

How do you make a workbench, when you don’t have a workbench to work from? In this series, Paul shows every step on how you can make your very own workbench.

Click here to view Frequently Asked Questions

Tools Used

- Square

- Knife

- Pencil

- Tape measure

- Combination gauge (or marking gauge plus mortise gauge)

- Tenon saw

- Handsaw

- Chisel set ½”, ¾” and 1” (12mm, 18mm and 25mm)

- Chisel hammer or mallet

- Smoothing plane

- Brace and bits (or screw gun and bits to suit)

- Router plane**

- Plough plane**

- Rabbet/filletster plane**

- Hammer (steel)*

- 10” steel rule*

- Jack plane*

- 10” rasp*

- 10” flat file*

- Winding sticks

*Optional

**Optional but highly recommended

Equipment Used

- A workbench or improvised support of some kind such as:

- Two saw trestles or…

- a portable, folding workbench or…

- a picnic table.

- Seven or so 36” (91cm) sash clamps (for frame clamping and clamping the laminated top)

- Some shorter sash clamps, bar clamps or G-clamps

Appreciate the content…So helpful to one starting out…or for that person wanting to build in another style to perhaps enable more efficient function.

I am just now making the bench from the old youtube videos and blog series. So while this is not quite timely for me I will say that this introduction video when you showed off details of the bench answered a lot of questions I had about some specifics of the older design bench.

Also, check out the drawing. That is something that hasn’t been available before and might still help you with some of the details.

Good luck with your bench build.

Joseph, I’m building from the plans. The leg dimension appears to be 1 and 1/2 inches too long. Perhaps the designer forgot to add the top plate into the figuring. As I was building, I stacked the parts on top of each other to make sure I’d done it right. It measured 39 1/2″. Easily corrected by taking off the measure on the legs to shorten. Thought you might want to change the plans. I so appreciate this site. I”ve learned a lot. Paul sure makes it look easy. No so for us amateurs .

Hello Chris, glad you’ve been enjoying the sight.

As far as I can see the measurements given are:

Legs 34 3/8″

Benchtop 2 3/8″

Bearer 1 1/4″

Which gives the 38″. Does that help?

I notice the cross-member between the legs has been increased from 4in to 6in wide compared with the earlier bench Paul made. Was that found to be a weakness in the old construction?

Hi Alan,

Paul says:

No, not really but the wider shoulders do increase the lateral stability. Probably an overkill but it looks great.

Kind Regards,

Izzy

I am also in the same boat and am well over half way on my build, cross referencing from the blog series, the YouTube videos and Paul’s book.

Don’t look at it as a problem, use it as an opportunity to figure things out for yourself – it’s part of the charm.

Admittedly, however, it would have made my life a lot easier, that said, I can use this new blog series if I wish to create a second workbench with the skills I have learned from the first.

Fantastic! I can’t wait to build this bench! Thank you Paul and Team!!! 🙂

Really looking forward to this Paul. My first ever introduction to you was on youtube watching you make your workbench in your garden. It was so inspiring.

I’ve just completed a green woodworking course making a Windsor Chair and I’m still hooked, more than ever.

Keep up the great work guys.

Rob

Hello Paul and Josep, I really liked this project and it seems a great success for you, in the flyswatter I gave my opinion but instead I liked this, The plans have improved and although I already have a bank done because I continue I’ve been with Paul for a long time since I released the series on DVD some years ago, we’ve been almost five years and I consider myself part of the team,

best regards

I am so HAPPY about this project!!!!!

I can’t wait for this series to begin!

Clamps aren’t mentioned in the required tools, does this mean there’s an alternative way to laminate the boards? We can see clamps in the video.

LOL obviously it’s a mistake… well spotted!

Hello Mathieu, thanks for pointing this out. I have added a list of needed equipment above. Best, Phil

Philip I wonder if the well board could be 3/4 ?

Hi Allen,

I passed your question on to Paul and he said:

Yes, no problem. It vibrates more, rattles more, but that’s not an issue, we can live with that.

Kind Regards,

Izzy

Thank you for this

Just want to say your videos and instruction is massively appreciated. We, me, us, the world! might not comment on everything, but rest assured folk are interested and are watching intently.

Thank you very much

Not that your videos where ever bad, but here lately they have seemed to be really professional looking. You all do wonderful work in everything that you do.

Looking forward to the rest of the series

I’m married with twins and one on the way,as well as finishing up a two year apprenticeship and coming up on my 4th year of college…and I’m not even 30 haha.

My life is constantly moving so quickly it’s hard to keep- Until I stumbled across your videos online. Your coarse sensor of humor reminds me of all the subtle jokes I overlooked growing up. Your precise words and reaffirming tone, along with guidance, make us all feel like we can accomplish what you teach. Most of all, you introduced so many of us to an art that was almost forgotten and in my case, a place to rest my mind and escape for a little while.

Thank you for sharing your knowledge, wisdom, talent, and sense of humor; that’s not abruptly followed up with a laugh track.

I hope all is well and that this and all the other comments make you feel as special/empowered as you’ve made us feel over the years.

Thank you so much Paul and team – you are the best!

Thank you so much for this new workbench series! I am looking forward to seeing more of the updated design and beginning my own workbench build. I hope you will comment a bit about the trade-offs of this single-top bench versus the double-top bench in your original YouTube series and about the 66″ length versus a somewhat longer bench if space in one’s workshop allows. In other comments over the years, you have said an ideal dimension would be 30-32″ wide and 72″ long for stability. So, I am curious about the tradeoff in using the current design’s smaller dimensions.

I second this comment. I was just about ready to build the larger bench when you notified us about this one. I am holding off building for now until I understand the insights of this design.

Consider this comment officially “third-ed” (it’s a word…) I’m excited to build this bench, but I’m interested to know what, if any, the tradeoffs are for a single sided bench, and a slightly shorter one, versus the youtube version with a central tool well. 🙂

Sorry but the background music was to loud. Hopefully the new viewers will not be put off by the unusually loud music. Paul’s other episodes aren’t overbearing with music as this one is!

As for the workbench; I’m excited to see Paul build this because it appears to be very simple lar of the exactly the same as the one we have seen him at for the past 5 years! I wish we could get his ever popular vise though?!

Thank you very much Paul!!

Not knowing where you are I don’t know whether this info is of any use to you but I recently found an original Record No 53 E with 10.5″ jaws for £28 on eBay.co.uk. It was in immaculate condition apart from some light surface rust and a bit of stray paint, all easily removed. It was in far better condition than my own which has suffered badly over the fifty-odd years I’ve had it due to rather adverse weather conditions where I live. However, it still performs just like Paul’s with a solidity which is difficult to find in more modern day equipment.

Good hunting!

I am also building mine with the information of the first videos you did and the blog series, this is fantastic and it’s been quite a challenge for me because I am not experienced in carpentry and have limited tools but very excited with the task, I like to say that this master classes and YouTube videos has been a great success and I want to thank you for all your work and effort to help me and others to achieve the knowledge in a very practical way and specially the enfasis in the use of hand tools, because it has show me that you don’t need all this expensive tools that are in the market and still do almost anything you want with small budget, thank you very much, keep the track!

What type of wood, would you recommend for this project?

Any wood is great. Simple pine construction lumber will work great. I can attest to this as I’ve build his previous tank down one from 2×4 and 2×6’s

Agree with this. Paul has said “use the wood available to you” and he typically builds these benches from construction grade softwood lumber from the home supply stores: SPF, spruce, southern yellow pine, douglas fir in the U.S. I’ll be building my bench with spruce and southern yellow pine boards salvaged from 12′ pallets.

Chris Schwarz gave me the idea of Southern Yellow Pine construction lumber – it is hard and stable, and easy to work. He noted that wide and long pieces have the best chance of being good wood. I found a Home Despot nearby that had 16 foot 2 X 12’s that were very nice and I paid 55 cents a board foot. After 11 years of use, I would do it again.

did you let it dry out first or just use it off the shelf?

Love the idea of this one being more compact.

Can you adjust the mic a bit, it sounds a bit far or muffled. Maybe a more directional one is needed to perk it up. Love your content guys and keep up the good work. I’m also going to request the hand tool book for Christmas this year. Thanks for putting that together and offering it to everyone.

So excited to see this series – having just finished making the diamond sharpening plate holder and strop, and got all the equipment together, this will be my first ever PROPER woodworking project, and I can’t wait!

It was the ‘workbench in the garden’ series that first got me interested in woodworking and Paul Sellers, and since then have attended a couple of excellent classes too.

I am very happy to hear about the upcoming new workbench series.

Will patiently wait for them.

Thanks a lot Paul, Josef and Team.

PS. Will have to give credit and say that the videography is very high quality, nicely and artistically done.

Well done friends.

Thank you Paul & team for this wonderful new project.

I have a few questions regarding my first workbench build, which is 40″ tall, 23″ deep & 72″ long made with wild jack tree wood which is a native species. Specifications below.

Benchtop: 2 3/4″ X 10 1/2″ X 72″

Apron: 1 1/4 x 9″ x 72″

Wellboard: 3/4″ x 10″ x 72″

Legs: 2 3/4 x 3 3/4″ x 36 1/4″

Rails: 3″ x 2″ x 24″

Question 1: Is the top work space width sufficient for furniture making or should I add an inch or two?

Question 2: What should be the depth for housing dado for aprons given apron thickness is 1 1/4″ ?

Question 3: Are the rails of sufficient dimension? What tenon size should I choose 1/2″ or 3/4″?

It would be very helpful if Paul or someone knowledgeable would be kind to reply.

Sorry for the delayed response. It is hard for us to go though the details and advise whether it will work out for certain without trying it ourselves. Some aspects, such as the bench top, are personal choice.

For other aspects it is hard to say if there will be sufficient strength. The measurements we have given are a guideline of what has worked, which can be carefully adjusted depending on available wood size.

Otherwise we can’t really go into individual builds. Sorry not to be more helpful.

Phil

In the USA, a 4×6 (3 1/2” x 5 1/2” ) ripped lengthwise would just about get you to Paul’s specs, minus a kerf. Pick through until you find one with no pith.

Video looks and sounds great! Have been gradually gathering the tools and preparing a cellar workspace to build the previous workbench, so this is great timing. To echo comments above, I’d be interested in the evolution from the previous bench to this design as well.

Thanks so much for all the team do, David.

Your Youtube series on building a workbench using 2X4s for a “Robou” like top was thorough, inexpensive, educational, something a novice could accomplish. Why deviate from it?

Although I like the previous workbench video, I have been eagerly anticipating this smaller workbench video series and will build this one first. I am glad for the addition of another alternative to building a workbench.

OMG so excited! I am still building the bench from the youtube series but eagerly anticipating the new series. I like the idea of a fresh perspective. I was about to cut the ends of the benchtop to length, then work on the aprons.

Grandpa Paul and his trusty sidekick Philip have done it again!

Where do I begin? The positive, upbeat feeling of starting a new adventure in the clip made me smile the kind of grin you get when you have that first warm spring sunshine after a long dark winter.

Well done, gentlemen.

Very much looking forward to this video series as over the next few months I’ll hopefully be able to start on my own.

Having watched the original bench build (on youtube) multiple times, I’d love to know what Paul has changed from that design and why.

To see you doing this in a space more like my space is also incredibly refreshing.

Regards,

Darren

I have made my bench from the original youtube videos, but will look forward to viewing this series and perhaps it will show me some of my mistakes. My vice was difficult to instal and it is crooked, but it is working and I can use it, which is the main thing. I look forward to that section. I would recommend to those who think it is too difficult to give it a try. If I can do it so can you.

First traditional woodworking project ever was this about 3 years ago. It’s been the focal point of my passion (obsession?) but I started a new one that hopefully won’t have the same thousand mistakes. This video could not have been timed better. Many thanks, Paul.

I already made my workbench–most important project ever–used poplar since I can’t find any decent white wood in the US. BUT I’m still looking forward to this series!

Chris:

http://www.google.com/url?sa=t&rct=j&q=wood%20locator&source=web&cd=1&ved=0ahUKEwjGx4z3-Z7XAhVQ0GMKHVL0DQMQFggdMAA&url=http%3A%2F%2Fwww.woodfinder.com%2F&usg=AOvVaw1fZ_eaCjQWYchFNW25Ujpg

How does one determine the height of the bench? I’ve seen materials and videos that seem to contradict one another. I am 6’6″ and suggestions by Jim Tolpin’s videos seem very small to me. Another suggested to “try benches at different heights.” Every bench I’ve tried (mostly at local classes) is far too small. Any suggestions?

I am also 6’6″ and had this exact same dilemma and now have a tall workbench that is too tall for just about anyone else to work at but is perfect for me. This question is very loaded and I have come to the conclusion that everyone has different ergonomics so no one can really answer it except for you. I know some guys who swear by the crease in the wrist height, and usually they argue it so you can bear down hard on your hand planes when planning, but paul has shown this to be bad form. For me I made it a little higher at about my navel. I determined this one day by stacking blocks under a pair of saw horses with a board on top of the horses. I kept raising the height of the saw horses until I found a height that felt natural to me and where my hands wanted to be when working a plane or chisel. this was around 45 3/4″ for me so I built to 47″, and ended up cutting it down to 45″ at the end. Shorter friends of mine cannot even stand comfortably at my bench, but I have yet to experience a sore back, sore shoulders or wrists at my bench as a result. I would suggest you do as I did and experiment a little using what you have until you can find an approximate height you feel comfortable at , then adjust as necessary once the bench is constructed such that it fits your personal ergonomics.

I’m with Ken — you have to experiment. Height is kind of a meaningless measurement in this case, because maybe you’re tall overall, but you have relatively short leg lengths, while your upper body is very long (eg Micheal Phelps, the US swimmer) or maybe the reverse. Long arms vs short arms will also factor in. How’s your back? Some people don’t mind bending, some do. Vision — some people have hawkeyes and can see ultra-fine marking lines while standing perfectly upright, others need to wear reading glasses and have their faces inches away from the work. Some people will be adaptable, and can deal with a wide range of bench heights, others very particular.

All these factors and more will play into your preferred bench height, and nobody has a magic formula.

When I built my bench 40 years ago, i was almost 5’11” tall.

the plans called for a 33″ height, which seemed too short for me, so I settled on 35 1/2″ and have never regretted it. Part of the reason I settled that is that my home shop was small, and I didn’t want a bench higher than my table saw ( yeah, I know— gasp). The height was in fact the same height as the saw and I could rip material and use the bench as an out feed table of side support for large stock.

Now I’m almost two inches shorter and the bench still fits pretty well. I have made appliances over the years for certain tasks ( dovetails, saw sharpening) and a high vise that clamps into my face or tail vise for carving and such.

But for my current 5’9″ , I am perfectly comfortable for face and edge planing on the 35 1/2″ height. That would translate as something in the 44″ range for a person 6’6″, I would think.

When I read that Paul considered a 38″ bench good for people my height range, I propped mine up and tried it, but went back to the old height. Maybe if I started at a taller height I could have gotten used to it.

Maybe the best approach is to start with a taller bench and then cut down as needed…………..

For Paul’s design, that might be true.

My bench was easy to increase, but cutting it down was a major rebuild, since the stretchers formed The feet and bench supports.

For assembly and fine work the bench can be really high, but I think the determining factor is planing, not because of ‘downward pressure’ as some folks say but because of control. When your underarm and upper arm are at less than 90 degrees I think you don’t have the fine control anymore you may need when you are doing some finer work with the plane. So I chose the height such that with typical stock on the bench my elbow is still a bit higher than it to get the right underarm/upper arm angle, that is my elbow is about 15 cm higher than my bench, which gives me a 99cm/39 inch height.

Paul did several posts on the issue.

Try this link and the other links on that page. I think he’s 6’4″ or something like that.

https://paulsellers.com/2012/10/the-long-and-short-of-bench-heights/

Sorry, I was thinking of another woodworking personality Paul’s around 5’11”.

The other fellow recommends shorter benches.

This is perfect, I’m half way through making a bench just like this adapted from the older youtube split top bench. The plans are great!

Oh yeeeaaaa….!!! Been waiting for this one Paul!

Can’t wait to start…

Thank you Paul!

Tassos Aristidou

I was at Oxford Wood Recycling today buying wood for the workbench, when I noticed someone else with Paul’s PDF cutlist also buying wood for a bench!

I’m sure this will be a popular build. 😀

Darren.

it will be long to wait for the next week

The timing of this couldn’t be better for me. Next week starts the migration of my shop from my basement in to a brand new shed. Building a new bench is the first step of that process. I had planned to modify the design from your old videos, but it appears these plans are almost identical to what I was going to do anyway.

I will also second the note from others regarding the improvements in your videos. It appears that over the years you (and the entire team) have improved your skills with filming.

Anyway, I’ve already drawn up plans for the You-Tube video series work-bench to suit my requirements and ordered the wood. As this new bench build has a greater tool requirement than than for the YT series work-bench (at least as far as “optional but highly recommended” tools is concerned) I’ll be sticking with the original work-bench together with the basic tools and my poor man’s router!

How much harder will it be without a plough plane? I have a rebate plane, and a router plane, but I lack a plough plane, unfortunately. Should I wait until I can afford one before making the bench? I still don’t have a workbench, and I was planning on making the one in the youtube series, but I procrastinated until I learned that this series would be coming soon, so I’m very excited to build this project! 🙂 I just don’t have a plough plane, and the equipment list says “optional but highly recommended” I suppose that means that it’s *possible* to do without, but much more difficult?

PS: do you think this would be a good “first project”? I’ve whittled some handles for my chisels but other than that, I really haven’t built anything. *sheepish expression*

Interestingly the original workbench video (on YouTube) did not have the slotted version of the well board. I followed this version for my first project about a year and a half ago and am very pleased with the results. I made a 5 foot version (for my available space) and a single work bench area like in the new version. While I do not think that the slotted version is necessary it is a reasonable addition.

I’d say start making with what you have. I don’t have a rebate plane, hell I don’t have a tenon or dovetail saw just a panel saw with 10 tpi. It’s amazing what you can do when you just start. It might be awkward at points but waiting for all the tools will only stop you enjoying woodworking today. Doesn’t have to be perfect, just good enough. I say this because I am a perfectionist and I let that stop me in the past, then I never did much of anything.

I don’t have a plough plane either but what I do have is an old cheapo circular saw which I think will cut the rebate and groove just fine.

Ian, that’s a great idea! I feel kinda silly for not thinking of it, actually. I don’t enjoy using a circular saw, and I’m not super experienced at it, but I can manage…and that means that I have one less excuse for not starting this project! Awesome! 🙂 Thank you. I almost didn’t ask the question at all, but I’m so very glad I did.

Thank you so much! That’s pretty much been one of my biggest issues (believing I have to have all the tools beforehand, and I must be absolutely perfect at using them…before I use them…yes, it is an odd problem to have, heh) with starting anything. I tell myself I’m not good enough, or I don’t have the right tools, or I need to watch more videos/do more research to ensure that I don’t screw up, etc, etc…and it just builds up bigger and bigger, y’know? So thank you for your wise words. I think it was exactly what I needed to hear at this moment. 🙂

I will use some offcuts and make a few practice cuts. Like you I don’t have a very big set of tools and to be honest I don’t have the money to buy some of these expensive ones. Even so I think that the circular saw will do just what we need. I am making some timber dogs too which should make up for my lack of large clamps. 🙂

Would this workbench work outside? I have a covered porch on the back of my shop and would like something I could to work outside on when the weather is good.

Hello Mark, you could store the bench outside but it will absorb atmospheric moisture and that can lead to distortion over long periods.

Hello,

I’m fairly new to this level of woodworking and have been working thru plans for building a workbench with an eye for this one. So this question is really to understand feature and function along with insight to my budding craft. What is the purpose or use of the wide apron?

Thank you,

John

Hello John,

Aprons help prevent racking, which is the bench twisting in use. So they make the bench much more solid.

Hi there Paul and team,

I see that at some point we will be also using bolts to secure the aprons to the legs and i wanted to buy those to be ready. What will the size (length and width) be of the bolts to be used? From the diagram i see that there is a mention of 1 1/8 (“to center of hole”). Can you please help me?

Thanks

Hello Tassos,

We used the following:

Bolts & nuts:

4 of ⅜” x 5” / 10 x 130mm

Lag screws

2 of ½” x 2 ½” / 12 x 65mm

4 of 5/16” x 2 ¾” / 8 x 70mm

Thanks Philip!

Also, I forgot to mention that you need washers for the bolts and for the 2 1/2″ lag screws and 2 of the 2 3/4″ lag screws. We will add it at the top of the page shortly.

Lovely! Thanks again Philip.

…and a SPANNER to tighten them! That wasn’t mentioned in the list. A broom to sweep-up afterwards…

Love this Series everyone, Paul’s original bench build is what set me on the path of handtool woodwork. What is the posting schedule going to be for this?

Whoops, I see now every 2 weeks! Thanks again!

When does episode 2 come out?

Nevermind…I missed the part where it said there will be an episode every two weeks.

Just looked at the cutting list–it looks like the wellboard design has been improved/fitted more precisely than when I built my bench a couple of years ago. Looks like it fits via a groove/dado now? If so, I like that improvement–great way to prevent the issue of sawdust filling crevices and things getting stuck in the cracks in my wellboard.

Hello,

Again a very interesting serie I will follow carefully!

I have learned a lot from you. Thank you to Paul Sellers and all the team for providing so much content of such quality! It’s really unbelievable!

My family is enjoying a lot little projects I’ve been able to build thanks to your lessons!

I have to replace my workbench which is not sturdy enough for handtools.

I’ve got one question : I am used to have the top protruding and I usually use it for clamping. WIth the apron in front it won’t be possible.

I’m thinking about solutions like :

– fitting the apron underneath the top instead of against the edge of the top

– adding a piece against the apron.

– adding some holes on the apron to let the head of the clamp coming underneath the top.

of course it will necessitate also to fit the vice differently.

but i don’t know if these ideas are really suitable or not.

Thanks.

Sorry for my English, It’s not my native language.

Hello,

Am I the only one concerned about clamping on the top of the workbench?

any idea to be able to do it with this plan?

thanks,

Ludo.

Paul has an alternative suggestion: put one clamp in the vise, and use this clamp (horizontally). Different designs of bench bring different ways of clamping and fastening; the bench really is a tool.

For what kind of operation do you want to clamp on the top of the bench? Let’s find answers for your situation.

Thanks for your answer.

I often clamp my sharpening board on the top of the bench.

Also I regularly clamp thin wooden pieces to plan thin boards on the bench. Thin boards tend to bend on their lenght if I only clamp them in the vise.

The best solution I think about is to create holes (2 or 3) in the apron in order to be able to use small clamps.

Another solution (to be combined depending on the case) would be to have dog holes, but I’m not sure on the good way to do it.

Regarding the alternative proposed by Paul, now that I have improved the clamps with a piece of pine Inside it, I will be able to use it. But it will useful only for boards too wide to fit in the vise but also thick enough not to bend.

For the sharpening board, You can add a small strip of wood to the underside of your board that clamps in a vise like the one Paul includes with his diamond plate holder. He has a tutorial on the build that clearly shows how to fo that. I have found I don’t need that, and instead just glues some silicone shelf liner to the underside of my board and that allows me to sharpen anywhere on the bench. I use a solid silicone shelf liner, not the perforated kind Paul uses.

Planing thin boards is usually done against some sort of planing stop that requires no clamping. For small boards, you can make a simple appliance like this – https://youtu.be/__T5B7FqX54

It can be clamped in the vise if you want to keep it steadier, but it saves lots of clamping.

Larger pieces can be held with a thin board that likewise clamps in the vise or with other appliances that also do not require each board be clamped to the bench. Just google “planing stop” and “Doe’s foot” for some ideas.

Veritas makes several varieties of metal planing stops, but I don’t use them as I am averse to using metal stops near the planes I have spent hours tuning and sharpening.

I guess I’m a chicken.

Lastly, I have planed really thin boards by sticking them to the bench top with double faced carpet tape. It works well and you can usually plane several board with the same piece of tape.

Thanks Larry Geib for your help.

It gives me many ideas.

(sorry I cannot reply to your post, there are too many answers I think)

Or you can walk to the end of the bench and clamp where there’s no apron.

Hi,

Im trying to work out my timber so I can order it and get started. I was looking at the dimensions listed and when trying to find local (Australia) construction pine I am having to make do with what I have by changing the dimensions slightly. I have however ran into an issue with trying to find timber big enough for the well board. The dimensions call for 320mm Wide however in Australia the largest pine construction grade timber is 290mm! Are we expected to laminate the well board?

I am also thinking I will have to Laminate the legs as well because there are no rectangular sizes even close to the dimensions listed. I would either have to get 90 x 90mm legs or laminate in order to reach something similar.

Any help is much appreciated. I’m very new to this.

Hello Warwick,

You certainly can laminate the well board. I would expect that most people will. You can also laminate the legs, as long as you take into consideration where the mortise hole will be. 90 x 90mm sounds great.

Hope that helps.

Hello Paul and thank you for the wonderful share of this build.

I’m not quite sure though how this workbench stands compared to the 2012-2013 version?

Is this an improved design? A different build?

Thanks in advance.

Hello Alexandre,

Here are the main reasons:

1. This bench is smaller, it is shorter, only has one side, and is easier to move

2. This series is more thorough (we missed showing vise fitting last time)

3. This bench build includes full measurements (you can still adapt it but you have a solid starting point)

Best,

Phil

Can you post the make and model of the vise Paul will be using? It may take a few months before the episodes get to the vise, and during that time some good deals may come and go. I’d rather buy the vise early on sale than pay full price when the episode arrives.

I suspect Paul will say any number of vises will do, but I’ve found doing exactly what he does the exact way he does it works best the first time I do it. (After that I can modify it.) Thanks.

I believe he likes the 9 inch eclipse quick release vise (someone please correct me if I’m wrong). At the moment, it’s at an all time high on Amazon, so I’m keeping an eye on it. The lowest it’s been is $84, but it has averaged $110 over the years.

Although Paul mentions the 9″ in recent posts, the vises we had in class I think were the 10.5″ Lee Valle steel vise, and the 10″ Eclipse would be equivalent. I suspect Paul is saying the 9″ because it can be hard to install the heavier 10″, but my opinion is that the 10″ is worth the pain of installing and the extra cost.

My impression is that it is still early days for Paul testing the eclipse vises.

Hello Terrance (and others),

Paul does indeed use the 9″ Eclipse. He decided on this as the 9″ is easier for the majority of people to handle.

It’s been two weeks since Episode 1, isn’t Episode 2 due now?

It’ll take until February 2018 to see them all. Wood GROWS faster than this!

Better to watch old YouTube video, review the plans for this one, then freeze-frame through the Introduction to see how was made. Is anyone actually building this, in real-time?

I was also wondering if I should wait to have more episods before starting.

I’m wondering if gluing the top and leaving it for weeks before assembling is a good idea. It could maybe move, twist depending on the conditions.

At least you won’t need a Rebate Plane for the Well. If you make it now, it’ll shrink all it’s going to, before you get around to installing it next Spring.

I’m building it in real time as I was just about to start on the first version when I saw he would be doing another series. I’m not really in a hurry, but my goal is to keep up with the videos. I assumed the second video would be out a week after the first one, so I worked like crazy to get my top laminated in a week. It was a lot to do in a week though, since I’m a newbie, so I’m okay with stretching it out a little more.

That makes sense, the Bench Top could take a couple of weeks – especially as this is part-time for most people. But how can it span 9 Episodes? Why are they stretched-out over 18 weeks?

Episode 1: Bench Top

Episode 2: Leg Frame 1

Episode 3: Leg Frame 2

Episode 4: Well Board

Episode 5: Apron 1

Episode 6: Apron 2

Episode 7: Vice

Episode 8: Apply Finish

Hoping there may be an episode on fitting a drawer too… But like Erin I got the laminating done quickly assuming a weekly release of episodes, and now I’m sat twiddling my thumbs somewhat!

LOL – I’m half way through your original series that you did in the backyard! Good companion set to check my measurements and techniques with I am sure. Looking forward to this.

Is this design a portable (“knock down”) version? The doorway to my shop (which I cannot modify – this is a rental house) is just over 24″ wide, so if I built it inside my shop, it would probably be difficult to move out of the shop when the the time comes.

Hello Alan,

It is indeed disassemblable, as long as you make sure not to plug the two lag screws in the top of the back apron.

Thank you! Much appreciated!

Consider it stood up on one end, 45 degrees to doorway. Two legs through, rotate, other two legs through. You hum it…

Okay so this will be my first woodworking project outside of restoring a smoothing plane (which maybe counts?) and I’m a little perplexed by the lumber dimensions. I live in the US and so far as I know the 2 3/8 X 1 1/2 boards for the bench top laminations aren’t a standard size here. Should I just use 2 X 4’s and adjust the other dimensions accordingly?

The USA standard for 2&3’s is 1 1/2”x 2 1/2”

Functionally, there would be no difference.

Any box store or lumber yard will have them.

i just bought some spf 8’ commons kiln dried at the orange box store for $2.20 ea. If you pick though them you will find a few suitable pieces.

Lowe’s will have them as will any actual lumber company. I just needed a few, so I didn’t want to drive further for Douglas fir-larch ones, (#2 and better grade) which would be better suited for a bench top and only about 20¢ more.

That’s great news, thank you! So would the legs be the equivalent of 4 X 4’s?

Hello Karl, Paul used the equivalent of 3 X 4’s. 4 X 4’s would work, but you would have to figure in any changes to the joinery and sizing of components.

I very much appreciate this series being free. As s beginner it’s great that I can get my start this way.

I understand the difference between common and actual board sizes well enough but I was hoping for some clarification on the wood list to make certain I’m understanding it properly.

For the bench top, should I be looking to get eight six-foot 2x3s or should I go with 2x4s and plane them down to that 2 3/8?

The 2×3’s that Paul used were 2 3/8″ if that helps with clarification.. So I’d recommend 2×3’s.

How does this compare with Pauls’s effort of 5(?) years ago? I made that one, but am building another. Any suggestions? – dick

Here are the main differences:

1. This bench is smaller, it is shorter, only has one side, and is easier to move

2. This series is more thorough (we missed showing vise fitting last time)

3. This bench build includes full measurements (you can still adapt it but you have a solid starting point)

The placement of the lower stretchers is my question. A shelf or perhaps a cabinet underneath might be useful. If so, then would the 9 inch distance from the floor need to be reconsidered, say lowering it to 6 inches?

Is there a stability factor involved in the 9 inch measurement?

Thanks.

I might add – I have watched Paul make all of his mortise and tenon joints on all of the projects and still learn, despite the repeated examples. Thanks.

You could indeed move the rail closer to the floor. The main reason for them being a little higher is that it is easier to sweep under the bench when there is a little more room.

Hope that helps.

This info may be too time-specific, so please feel free to delete when it no longer matters. Amazon has the 9″ Yost vise (which appears to be a dead ringer for the Eclipse Paul recommends elsewhere) on sale for ~$60US as of today December 3, 2017. Just bought one myself for my upcoming bench build.

Thank you Paul and Team 🙂 Greets

I am so thankful to have stumbled across this and can’t wait to start. As one who is very new to this, I have a couple questions that I was able to find partial answers to throughout the posts above.

Basically it comes down to this: have any of you prepared a detailed shopping or cultist? For example, the plans give the bench top’s final dimensions, but it would be really helpful for a newbie like me to have a few more details (like: are those 2x4s? How much longer should I start with them before cutting it down to 66″? If I’ll need to laminate the wallboard and apron, what size pieces would you recommend starting with?)

Perhaps this is asking for more hand-holding than this project/site is for, but I figured I’d give it a try.

So if anyone has a shopping list for the lumber that I could easily get at a big box store, I’d really appreciate it (and hopefully this bench will set me on the path to more and more projects in the future).

For those of you close to South West London/Croydon – I’d recommend Fulham Timber Merchants as a good source of timber. I’ve just bought the timber for my workbench from them. Seven lengths of 2×4, seven lengths of 2×6 and two lengths of 4×4 (all “lengths” are 2.4m, or 8 feet). Total price £153 for very good quality PAR “redwood”. And the chap at the yard couldn’t have been more helpful, sorting through a couple of dozen of each size to make sure I got the straightest, clearest of the lot.

I’m building my bench a bit bigger than the one Paul is showing – a bit of a “mash up” of this one and the original YouTube one. I’d imagine the timber as he has specified here would be well below £100.

Very nice people to do business with!

https://fulhamtimber.co.uk

P.S. They’re not actually in Fulham – they moved out long ago.

A little different from the stuff you do, but white oak is white oak, wood glue is wood glue, and clamps are clamps … https://www.youtube.com/watch?v=5K0idbEuNV8

I will be storing the bench in an unheated garage where the temp goes down to 0 celcius. Is there anything special I need to consider?

Wear a hat?

Switch to Fahrenheit. 32 sounds so much better than 0.

I had the same question as i’ll be working in an unheated shed too.

Paul, or others, how do you feel about putting locking wheels on a workbench. I have a small shop and cannot put my workbench permanently in the center of my shop to work around it and get full utilization of it. Do locking rollers work or are there other methods that would still give me a sturdy work surface and yet allow me to move it to the side when I need the center space for other machines, assembly, etc.

From the horse’s mouth:

https://paulsellers.com/2015/02/lift-off-add-some-sidekicks-for-greater-movability/

I plan to work in an unheated garage in the bay area of california. Will this bench survive the humidity fluctuations we see throughout the seasons?

Hello Alex,

This bench is certainly designed taking wood movement into consideration, so you should be fine. You may have some planing to do once the bench has settled to re-flatten it, but that is nearly always the case.

Has anyone else had their workbench in places with a high fluctuation in humidity? Would be interesting to know how you got on.

Thank you Philip! I look forward to my build. Is it fair to say the same for the tool cabinet? I hope to complete that as well. All the best!

Alex, I would say so, yes. Does depend a little on the type of wood used, and make sure to let your wood to acclimate in their for a while before planing. The top, bottom and sides all have the grain running in the same direction to allow the dovetailed pieces to expand and contract evenly and the floating panel framed doors do the same.

My bench is in my unconditioned garage in Colorado. Pretty drastic swings in temperature and humidity seasonally, from 20 percent to 80. No problem, structurally. The top needs a slight flattening again after two years, but it isn’t bad enough for me to bother to do it anytime soon.

Paul, Thank you for this workbench. I had started on your previous bench design but had to stop in the middle. I can, however, use the laminations for that one to make this bench which is actually a better design for the woodworking I do. I will now be able to complete this bench quickly and get to work. I am very excited to have this design to work to. Thank you so very much. – John

I completed the bench in 9 days, 8hours a day. Sadly using low-quality mexican Pine from Oaxaca because that is all I could find in Yucatan Mexico. Here are the pictures in this album https://photos.app.goo.gl/ElPHd7vVyE8AAH9x2

The pine may have been low grade but you have made an excellent job of building the bench – well done

Thanks

Well done, Carlos! Thanks for including a photo of your tools too – that’s an interesting historical part of a big project. Maybe tape a copy of that to the underside for the future. The only thing I didn’t see that your bench needs is the signature of its craftsman.

Will do, thanks the for advise

I wonder why the aprons are so deep. Most would store things below but perhaps this has an advantage?

Aprons help prevent racking, which is the bench twisting in use. So they make the bench much more solid.

I’m making this bench, but due to space constraints, it will be 60″ wide, rather than 66″. How should I best adapt the positioning of the legs to accommodate this change?

Shouldn’t be too critical. You could take an inch off either end, and 4 off the middle.

Just glued up my first frame yesterday. I opted to not use the haunch on the top rail. The diagram said it was optional. I’m wondering what if anything I should do about the one inch gap at the top between the legs where the haunch would have filled in.

Hello Rodney. Think there is a little bit of confusion about the haunch. Paul doesn’t use a haunch in his build, but removes the whole top 1″ of the tenon instead. This makes it flush with the top of the legs.

In your case, you could screw and/or glue a piece to the top of the rail that brings it flush to the top of the legs. Then the bearer can be screwed and glued into this. Or you could use long screws and screw and glue the spacer and bearer into the rail at the same time.

That make sense?

Perfect sense. I ended up attaching a piece to the top of the rail. It worked well. The four mortise and tenons for this project were the first four I’ve ever made. My first attempt was to follow the plan prescribed by Paul but my mortise for the top rail ended up too long so I decided to make the top rail mortise and tenon the full width of the rail extending the length towards the bottom of the leg. Thus I ended up with the inch gap.

I just installed the top pieces to the frames and did a final leveling and sanding. Its awesome! Love my new workbench. Thanks for getting back to me.

My timber availability is different species. Would it be more stable to use different species for the legs than the rest of the bench, or to laminate them from the same material?

Hi Keith,

Either will work fine. The leg frames are constrained enough in any direction they might expand or contract.

I could not find overall dimensions for this table in your video, website, or plans download. The tall and the short of it is, I need to adjust it for my awkward height! Can you help? (maybe add it to the plans) Thanks!

Hi Tod, the overall dimensions are on the last page of the drawing linked to above. We’re using a mean height of 5’10” and found that most people that height prefer a bench height of 38”. That being the case we suggest that you add or subtract inches according to your personal height. To be on the safe size you could make the bench an inch higher as well as work standing on a block and then work at the bench for a short while, see how it feels and cut it accordingly.

I wonder about some of the design decisions. Did Paul discuss where he places the vise in the not-yet-posted episodes? Why use the 9″ vise since they make a bigger one? I’m sure much of this is personal choice, but I don’t have enough experience to tell if I’d prefer one location or one size vise over another.

If I remember correctly the fitting and position of the vice is in one of his blogs. I remember Paul commenting that the selection of the vice is one of choice but that bigger vices become very unwieldy do to weight. I compared the 9′ Eclipse with the 10″ Eclipse in person at a local woodworking store and the weight difference was amazing – I went with the 9″ and have been happy with it.

The vise goes on whch ever side you ar comfy with. Rt or left handed. He also mentioned the 9 n was asier t install by your self.

I have the 10 in h on my outside bench and a 9’inch on my inside bench. The nine hasnt been a problm yet. I turned the big bench upside down when i put that vise on i built in the in side bench and did not have the luxury so was glad for the lighter weight.

A good project. My bench is 71″ long, just an inch longer than my old jerry built bench (this one doesn’t rock and roll!)

Although it started life as a Paul Sellers design I looked at other designs. I was caught by the idea that the front of the bench should have the legs and the worktop in the same plane so I retro fitted a front stretcher and added a couple of leg fillets to achieve this. This change also necessitated recessing the vice into the apron else the single frontal plane is lost again so the rear jaw of the vice is about 1mm behind the front of the apron. Plans to add a full width wooden tail vice are being considered. I have not drilled for dog holes at the moment but I can add these later if required.

Just a word about other bench designs. A number of American authors write and assume that you have available a full size table saw (with dado set capability), an industrial size thicknesser, a router table with all the cutters, a drill press and the facility to rip down 2″ x 12″ or 4″ x 8″ lengths of timber that may be 12foot or more long.

One author described his small workshop 15′ x 25′. I use one half of a small garage, a space about 8′ x 9′ (the other half of the garage doubles up as a print room and a photographic dark room).

The use of hand tools is what makes the Paul Sellers tutorials so useful. Most of us try to squeeze a quart into a pint pot, most of us have some hand tools. Thank you Paul for showing us what can be done with these simple resources.

I just completed my new work bench. In the end I hybridized Paul’s original youtube bench and this project. The PDF of the layout and dimensions were nice to refer to. I actually took my own sketch/drawing and compared to Paul’s to ensure I had not missed anything and it worked a treat.

Used dimensional SPF from the big box store( not the clearest around) but made it work. had to plane up quite a bit but with regular sharpening of my #4 and #5 1/2 managed to achieve a really nice flat top. It is amazing how much planed waste you end up with once you have finished all the rough planing.

Really happy with the end result having decided to wedge and glue the leg frames.

My favorite parts of the build were the rounded through tenons, the wedge system which is simple and solid, along with finishing the whole bench with shellac and finally 0000 wire wool with wax.

A big confidence building project……………

I built my bench but left out the well board. I thought it was to challenging for me and I don’t have one if those planes. So I made a couple changes to the plans but I’m extremely happy with the final product.

The only question I have is what would you recommend for the finish if anything.

I struggled with this one before settling on shellac. Diluted to around a 1 pound cut not exact,. I gave the legs and underside two coats to act more as a sealer, then applied several extra coats in the top and sill boards. when done a quick rub with very worn sand paper, 0000 steel wool and then used the steel wool to apply the wax. The finish is glass like but not high gloss. depend on what you would like. The shellac is easy to repair down the road if I have to re-flatten the top.

I also just finished my bench. I painted my legs, and I’m applying blo to the bench top.

What wood would you choose/recommend when you have the choice between yellow pine or ash?

John,

Obviously it really is a personal preference and depends on how you intend to use your bench. I think Paul was trying to show that cheap materials such as stud grade lumber can make a very functional and cost affective work bench and many of us have followed that lead.

From my stand point having used SPF lumber it was an odyssey to really see how nice a product I could make using cheap materials but also honing those other skills such as maintaining the sharpness of your tools to a achieve a great end product.

Like Paul says ” it’s not what you make but how you make it”….Good luck with your build.

I agree with Paul Bowes — it’s not what you make but how you make it. It won’t make a fundamental difference, and there is no right nor wrong choice.

The woods have significant differences, and while both will make fine workbenches, you might make a choice based on their working characteristics. Ash is a ring-porous hardwood, significant difference in hardness between early and late wood, and has that grainy, coarse texture like oak. Pine is a softwood, so a big difference in working feel, probably everyone knows how pine works. If you have a lot of wood to remove, the ash will take a lot more effort, assuming all other factors are equal. Neither wood is known for moving too much. Southern yellow pine has a reputation for smelling nice when working on it, ash not so much.

You might look at your stock and choose based on factors like quality of stock – are both perfectly clear and free of knots or defects? Was the cost to you for both the same, and the opportunity costs identical? What about grain — are both 100% quartersawn perfection, or does one look more cooperative than the other? Are they both dried and acclimated to your shop?

Lots more that could be considered, but in the end it is trending more towards paralysis by analysis than wisdom to delve into the minutiae …..it’s a workbench; the end result will depend far more on you than on the wood from which you build it.

Hello all, thank you for your kind comments. We’re glad so many of you have been enjoying and following along with this project. We love seeing your progress and completed projects in the forums and gallery. There will be a number of follow up posts on common questions and additional features, so keep an eye out for those.

Thanks again,

Phil and the Woodworking Masterclasses Team

I have not been able to find the construction of the wellboard. Can someone direct me to the episode where it is laminated up and the sides are lipped?

The laminating of the wellboard isn’t shown if I recall correctly, but it follows the same process as that of the aprons shown in Episode 2. The final measurements of the wellboard are shown in the downloadable guide linked in the Introduction Episode. I used two pieces of board glued together.

Putting the sides on the wellboard starts at 18 minutes into Episode 7:

https://woodworkingmasterclasses.com/videos/workbench-introduction/workbench-episode-7/

Thanks, NICHOLAS !

please excuse the basic question. I have seen Paul mention the portability of this bench and ability to disassemble for transport. My question is, when he’s gluing up the top to the front apron, how do you keep the squeeze-out from gluing the top to the legs underneath? Thanks.

Be careful? 😉

Seriously, the possibility is only at two small spots but put packing tape, blue tape, or even a sheet of newspaper where there might be squeezout.

Greaseproof paper from the kitchen cupboard works well for this when using PVA glue. With epoxy (not needed for workbench), sellotape or brown parcel tape would be safer ie less likely to stick.

TAIL VISE QUESTION

Hi everyone. I am done with the bench. The distance from one end to the the legs is 9 inches. How do you install a tail vise here. I have an old record 7 inch one? Any help would be appreciated. I believe the record 7 inches is around 11 inches long.

thanks

Hello Hassan, as you see in later episodes, the vice is fitted inside the legs from the end, not outside.

Thanks, Phil

I’ve started making my workbench at last, I’m using old roof joists and timbers that were skip bound. I’ve had to laminate my legs using 4×2’s and some of my other timbers are different dimensions to Pauls but I’m changing the sizes on the plan to suit the timber I have. It’s taken me two days so far and I’m not quite up to video three but I’m loving it and determined to do as good a job as I can, it’s great watching it take shape. I’m using two of the saw horses which I made from this site, also a scrub plane converted from a No#4, two Ebay saws which I’ve been able to sharpen as a rip and crosscut pattern, a rusty Stanley No#4 and No#5 which I have been able to clean up and sharpen so they sing as they glide along and it’s all thanks to Paul and team and the brilliant way you teach, film and edit the videos. What a fantastic job you are doing! Thank you!

Hi Paul and Joseph. It’s my first time making work bench and doing good joints. I find it difficult and lose my confidence making furniture and other stuff as well. Comment me back please

@LEE1987TH you might try starting a new discussion / thread in the projects forum, posting some photos, and asking for specific help. I’ll bet a number of people try to help.

Great suggestion Ed. We aim to answer specific questions on the content of individual videos in these comment sections.

General questions can be put up on the forums (a very supportive and helpful community of people) or otherwise emailed in to us through the comments form. There is a lot of useful info available in the FAQ tab about the workbench.

Hope that helps and all the best with your project. It can b overwhelming and daunting when first learning woodworking. The only way through is practice and perseverance, but you’re in good company.

Best, Phil

I about 95% finished with my workbench; a combination of the one in Paul’s book “Working Wood 1& 2 and Paul’s youtube videos. I was quite a long way into the build when I discovered the current series on woodworking master classes.

I attempted to make the wooden plugs to cover the countersunk lag screw heads but there are areas of the wood block where the grain runs perpendicular to the downward stroke of the chisel. In those areas large chunks of wood break away from the block instead of the fibers getting sliced. My chisels are very sharp and the slicing works well where the grain direction is parallel to the direction of the chisel.

Has anyone run into this problem and what is the workaround?

Thank you,

Hi Ed,

Paul says:

The best way to learn this is to do it. It’s a technique that would take 3 pages to describe but as you’re in the process of learning this is a good time to start and you will soon learn which direction to slice the wood as you make the plugs. Believe me, you can do it.

Kind Regards,

Izzy

Hi Izzy,

Thank you for the encouragement.

A related side story: When I first started learning how to hand plane I practiced on a 2X4. By the time I finished I had an enormous pile of shavings on the floor and a 3/4 inch thick 3/4 x 4 .

Well, I’ve gotten a lot better by watching for the details in Paul’s methods and by doing (and doing some more). Most of the practice has been on the workbench and it has been a great experience. I feel pretty good about my planning (oh, and sharpening) skills now and hope to keep getting better at it.

When making the plugs, I think where the grain runs in a direction where it wants to come off in chunks I should pare with the chisel at an angle to the grain instead of perpendicular.

I tried this a couple of times and it seemed to work better but then, I had to put my tools aside to go see my kids on the other side of the country.

Back at it soon!

Thanks once again.

Cheers,

Ed

Hello Paul,

I will soon be staring the workbench, following your videos. Of necessity I am making the bench only 4 feet long so to improve stability I am beefing up the legs etc. The legs will be laminated from two 5 1/2″ x 2 3/4″ sections which will make the legs 5 1/2″ square in total.

My question is. Should I cut out the mortices in the legs before laminating, to save myself having to chop them out later or will, in you experience, having mortices through and in line with the glue joint weaken the legs due to racking forces? In which case, is it better to chop out the mortices through the non laminated faces later on? also, the bolts for the aprons would tend to pass through the glue joint as well which may cause a problem.

Sorry if this is confusing, I just need to know which face to cut the mortice through really.

Best regards,

Bob

Hello Bob,

due to space constraints my bench is also roughly 4’2″ long.

So I went the same way: beefing up everything to gain weight. The legs are also laminated. The glued area in each leg is so large and the mortices are relatively small and the loss of structural stability imho isn’t more than theoretical. Same thing applies to the bolts.

I laminated the legs first and made the mortices afterwards. Today I’d chop the mortices first, because marking the mortices accurately is much easier than chopping them accurately. Chopping before the lamination means that you have 4 faces to start from instead of 2 in the case of chopping after the lamination.

To minimise toppling tendencies, I built my bench with 10° longitudinal splayed legs. So the legs end under the end of the bench. And: I put the wedges on the “outside” of the legs.

Hope that helps,

E.

Thanks E. Useful information, especially the wedges. Stability shouldnt be a problem though as I can fix the bench to a wall with a couple of simple “L” brackets onto the rear apron.

Hello, do you have drawings of the workbench in Sketchup format?

paul – I have access to pine beams 3″x4″ that I could have for free. they would be perfect for leg material. The log sat at the lumber yard for a while, but they were never kiln dried. they were delivered and stored indoors for a couple months now. They are reading 10-13% on my general moisture meter. would you consider these usable for bench legs? If not, how dry must they be/any tips on getting them there/how close to final dimension should I chop them to as I wait?

General-Tools-MMD7NP-Moisture-Meter

thats the one im using, and it states it could be off by +/-3%, so even if it is as accurate as can be it may be as high as 16% in spots i suppose.

Hi Keith,

Paul says:

If that is a true reading, I would be surprised that the moisture content is so low after such a short period. Generally we allow 1 year per inch of thickness to dry down to that level. Sometimes the reading you get on the surface is not what’s inside. The only way to get a true reading is to cut the wood in two near the centre and measure it there. Alternatively you could weigh it and wait a month to see if there is any change. If the weight has lessened then it’s still drying.

It really doesn’t matter, you can leave the legs that size and they’ll work perfectly well. No point making work.

Kind Regards,

Izzy

i did saw it right in half, it was saying 13% inside and as low as 10% outside. I wasnt opposed to buying other material just wondering about using this free source, although I could always use them down the line on another bench. if anything it has me questioning the accuracy of my moisture reader. thanks for the fast reply.

I am taking down a large cedar deck on my home. Would any portions of this workbench be acceptable for reusing any solid portions of cedar? 2X6, 6X6, 2X12, & 1X4 sizes may be available once demolition is complete.

Hi Joe,

Paul says:

You don’t tell me what kind of cedar this is, but if it’s a true cedar then it is most likely that it will be too soft, especially for the bench top, whereas the leg frames could be made from softer wood.

Kind Regards,

Izzy

The only cedar I have worked with is Western Red Cedar which I think would be too soft for a workbench. Make some garden furniture with it instead. Some care may be needed: 6×6 structural cedar posts very likely have boxed heart (pith in the centre) which may twist and crack once ripped unless the pith is cut-out or kept encased. Small cracks and checks are aesthetically acceptable for outdoor furniture but avoid badly cracked pieces.

Thanks. I thought it might be too soft as well

Hi Paul

I’m going to be starting on making a workbench in the next couple of weeks and was wondering if there is any specific reason to go for the new version rather than the old build? I’m quite new to joinery having spent the last few years tinkering with making tables and the like for greenhouses and the allotment, I decided to take it a bit more seriously. I have enough room for the older version (looking at between 3 and 4ft wide by 6 1/2 to 7 foot long), and would like it to be double sided as I have the space and it won’t be against a wall. I don’t see PDF plans for the old one on the site but can largely figure out what is what from the video and the pencil drawings in an old blog post. I’ve already made the sawhorses and they are doing great, and I’m just finishing the shooting board before building the trestles to help with the bench build.

Best

David

Hi David,

Paul says:

If you’re talking about the smaller version pine one, then it’s more of a practical size for people doing woodwork at home. It’s the size I use all the time and it works great. If you’re talking about the plywood one, that was just an alternative for people who can downsize their plywood using machinery yet still want a robust bench.

Kind Regards,

Izzy

Thanks Izzy, Paul and Larry, it’s the pine one and I’m looking at making it around 3′ x 6′.

Pail still has the drawings and measurements up for his monster center well bench here:

https://paulsellers.com/2012/06/making-the-workbench-7/

It seems huge , at 3’x8’. You’d need a pretty large shop to work around it. Maybe for 2 people.

I wouldn’t make a bench any wider than I could reach across, of course the bench I have worked at for a very long time Is only 20” deep including the rear tool well, so I’m habituated to it.

We are going to pretend I typed Paul, OK? LOL

An “edit” link had started showing up on fresh posts. Very handy in such situations, but that functionality seems to have disappeared.

im using construction grade 2×10 for my apron boards. should I be concerned about some checking in the middle of them? they dont go the whole way through, but since theyre right in the middle its hard to tell how deep. the boards have no pith but are closer to the center of the tree than not. Theyre very nice board, only a few knots, tighter grain than most and very straight. but there are the small checks? I suppose I could cut them out and laminate pieces out of what I have but I worry about twist so try not to rip any more than I need to. they run about 12″ long and are about in the center of the board. I hate to buy any more lumber, these are really nice otherwise.

I have 3 2×10 to work from, I was planning on using 1 and a half to make each apron but the cracks, of course dont allow me to cut around them easily.

I think checks in construction grade 10 inch boards (so that’s more like 9 1/4 in the US) are fairly common..? I know my rails and aprons have them – my bench has been going very strong for over a year now and the checks haven’t affected anything. I wonder if epoxying them would do anything valuable?

have they grown any larger or stayed stable?

yeah Id say theyre common. i dug through a pile of 30 to find the three best I could and two of them have one small crack. There is a lumber yard here with premium spruce that is nearly s4s and clear, but they only have 2×4 in that grade, and I chose to try to avoid laminating 4 pieces together to make each apron

Hi Keith,

Paul says: It doesn’t matter, the checking is unlikely to progress any further.

Kind Regards,

Izzy

Thanks Paul’s I will just turn the checks to the inside of the bench

I noticed in one of Paul’s blog posts regarding workbenches that he had a sketch of his bench with a leg vise. Has anyone tried that? Im preparing to build my bench and I have a Yost 18” vise screw assembly and am planning on building it with a leg vise. Any thoughts?

Peter,

I and many others went through this exact thought process while building the joiner’s bench. How can you decide with so many vise options to choose from?!

What I will tell you is that I ultimately opted to move away from a leg vise for two considerations:

First, the all-important apron on Paul’s bench is not traditionally designed to be permanently mounted to the leg frame. The knock-down aspect to this bench is a terrific feature, and a leg vise would complicate that (but it could be done).

Second, the legs on this bench are stout, for sure, but you typically see leg vises on larger French/German style benches that have STOUT legs. Again, this could be navigated to achieve your leg vise, but another consideration to factor in.

I’ll end but telling what I ultimately went with, and that is a twin-screw Moxon-style vise. Specifically, I used the Veritas end vise hardware to create a face vise that has monstrous jaw capacity and tremendous clamping pressure. I absolutely love it! And, while I won’t spend another man’s money, I might add that you’re halfway there already with your Yost assembly 🙂 just my two cents.

One consideration with a leg vise is that you need to add in a parallel guide of some sort at the bottom of the vise to ensure good clamping. My very first bench (not a Sellers bench) had a leg vise using a Veritas tail vise screw. It worked well, but the adjusting the pin on the parallel guide got old after a while, and I went in a different direction when I built my second bench (a Nicholson style). There are workarounds, but they must typically be built in when designing the bench.

Another issue to consider is that most benches with leg vises have the leg flush with the apron. I don’t believe this is a big deal, but one aspect of a leg vise is that you can clamp long boards easily, and clamping pressure may be reduced when the leg is recessed a bit from the apron. But I haven’t tried it, so I am really just speculating here.

Nothing wrong with leg vises. They work really well, and look great when a massively thick chop is built. Plus they can be inexpensive to build. But, like anything, there are compromises that go with it.

Thanks for your input Matt and George, good advice all around. My second choice, since I’ve already invested in my single screw hardware, would be the Nicholson (I think) face vice, as shown off by Thomas Fidgen (don’t blame me for the artistic use of focus) https://youtu.be/iYldStIreQI. I like the unlimited depth in this style, and it seems to lend itself well to the aprons. I’m sure I’ll add a tail vice down the road.

Thanks again!

I’m gathering material to start my workbench. I have a 6″ jointer that I bought at an estate sale about a year ago and a 10″ table saw that I’ve had since I was a teenager (I’m 68 now). My original intention was to use these power tools to simplify building the workbench but then while I was watching a re-run of ‘Karate Kid’ for the umpteenth time I changed my mind. You know the story; ‘wax on’, ‘wax off’, ‘sand the floor’, ‘paint the house – side side’… It wasn’t about getting cheap labor it was about teaching the student skills and methods. I could probably knock out a workbench in a few days using my power tools but just having a workbench is not the goal. Winding up with a workbench is a plus but it is more important to learn some basic skills like sharpening and using a hand plane, sharpening and using chisels, using winding sticks, and making basic woodworking joints. So I’m still going to build a workbench but I am going to do it by hand.

I’ve recently had to move and having my workbench disassembled gave me the urge to paint it. I’ve been using it unfinished since I built it but now I’ll have to temporarily have it on a covered area outside. I’m wondering what kind of finish/paint will give it the best chance outdoors.

Hi,

Paul says: I would just use any outdoor paint, be that water based or oil based. The same stuff you might paint your front door with.

Kind Regards,

Izzy

I am about to start on making this bench. Instead of the solid wood top, could you use 3 pieces of 3/4 mdf laminated together for the top? I only ask because I have extra from another project.

Hi James,

Paul says:

You could use MDF, it’s certainly dense and solid enough, what the longevity offers I don’t know but it’s easy enough to replace!

Kind Regards,

Izzy

Any recommendations on what wood to get from the home store for these plans? What did Paul use and what stock prep had to happen?

I’m new but need a workbench to learn basics I feel other than tool sharpening. I’m looking at the cut list and, adding an eighth to all to plane down, I’m having difficulty seeing what actual sized 2x or 4x dimensional lumber would even work. Unless the intention is to need to rip everything down to thickness but then it seems not designed for cheap construction grade material.

For the legs as example even considering laminating two together, I’m not sure of anything that would work well. 2-3/4 by 3-3/4 being the final, so somewhere near 2-7/8 by 3-7/8 or even 3×4. Two 2×4 in the US would be 3×3-1/2, a quarter inch to plane down on one side and too short on the other side. Three would be 4-1/2×3, a lot of prep on one side at least. A 4×4 would be 3-1/2×3-1/2, too little on one side and a bit to rip down on the other. I thought it was designed for cheap dimensional lumber in mind but unless I’m missing something it seems maybe not?

It also seems like a workbench would be a novice item since it’s needed to get started. Ignoring all the skills used here, I’m wondering about that too since stock prep isn’t discussed.

I’m sure I’m misunderstanding a bunch of things. Any help here?

Hi Ben,

I see you questions have been answered below but please let me know fi you have any outstanding questions and we’d be happy to help.

Our sister site, Common Woodworking, focuses on beginner woodworking. I think you might find this useful and in particular this blog post on working without a workbench

Kind Regards,

Izzy

My twopenneth would be. Don’t get too hung up on the details. Adjust the build to suit the wood you have at hand, the space you have available, the funds you have available etc.. Look at a few other designs as well. There is a good article by Chris Schwarz on popular woodworking detailing what you really want a workbench to do, that does not focus on any particular designs.

https://www.popularwoodworking.com/techniques/10-rules-for-workbenches/

I’m not sure a novice should be redesigning a plan as their first step? I thought about this very thing but this thought occurred to me. Once you change one dimension so much else is affected I’d think. Shrug.

It’s not about redesigning the workbench from scratch, it’s about understanding what is available, and what your requirements are. As a simple example, if you have a plan for a dovetail box that calls for 10cm high sides, and you happen to have some nice 8cm width wood, then you have a choice. Use the wood at 8cm and get on with the making a nice box, rip and joint and glue to make 10cm boards, go out and buy some 10cm boards.

A factor for that choice is what the box will be used for, and where it will be used. If, for example, it will be used to store something that is 9cm high, then your choices have reduced. Another factor is whether or not you have enough of that nice wood to be able to make 10cm wide boards.

I made my workbench from the video and blogs of 2012 (the workbench built in the garden).

I have used recycled wood with various dimensions while Paul used 4X2 (UK sized).

I didn’t bother to make the legs exactly the same. The left ones are about 140 X 57 mm and the right ones are about 135 X 57. So I made the right dadoes in the apron about 5mm wider on the right side (anyway, the wedge would take care of such a small difference).

I ended with a 70 mm thick top and used 30 mm thick bearers, so I cut the legs to be (38″ – ( top + bearer thickness)).

I have used 85 X 30 mm lumber from an old picnic bench for the rails and aprons.

When making the two leg-frames (2 legs, 2rails and a bearer) I Just made sure they were of equal depth (front to back) and height.

My workbench is rock solid.

(about 1.5 m long X 0.6 m total depth)

I patterned my workbench after the English Joiner style, rather than the ones in the videos here and on Paul’s Youtube channel. It’s about the same size as yours Benoit, and I also made my legs out of recycled wood. I only had to buy 3 × 3m long 4cm by 30cm planks from the local Obi store. The height is based roughly so that the top is roughly where my hand hangs when I am standing, and the length is based on halving those 3m planks.

Hi,

I am about to start building my workbench! I watched the videos and read through the information on here and am already quite excited. I have two questions, though:

1. Why are the wedges faced downwards? As I understand it, I would not be able to put much pressure on them to force them into place. If I were to flip them upside down (with the wide end down), could I not drive them in from below and would be able to tighten them easier?

2. I am starting in the basement of our apartment building but hopefully I will be able to move to a larger workspace at some point so I am concerned with dismantling the bench. As I understand that is possible by unscrewing all the screws, but would not the bench top and front apron be rather awkward to handle as they are glued together? Could I screw the front apron similarly as the back one or would that not suffice to keep the edges to the bench top flush?

Thank you so much for all the amazing content!

Hi,

Paul says:

The wedges self tighten with the vibrations of daily working above, on the bench. It works.

It is not too awkward as long as you remove the vise. Even so, a second person resolves all issues.

Izzy

Hi Clemens, the wedge direction means that they will self-tighten by gravity as the bench shifts and/or shrinks over time. If the apron recess is cut accurately to size, you won’t need to drive the end of the wedge to tighten it.

Ah, that makes sense! Thank you!

As long as one leaves at least a minimal space between the top of the wedges and the underside of the workbench-top/tool-well, if necessary, one can apply pressure on top of the wedges with a prybar or a strong screw-driver.

So if you don’t expect the wedges to shrink under compression when installing them (which would drive them lower and create the said space) cut a few mm at the top of them. Although that was not needed with my pine wedges.