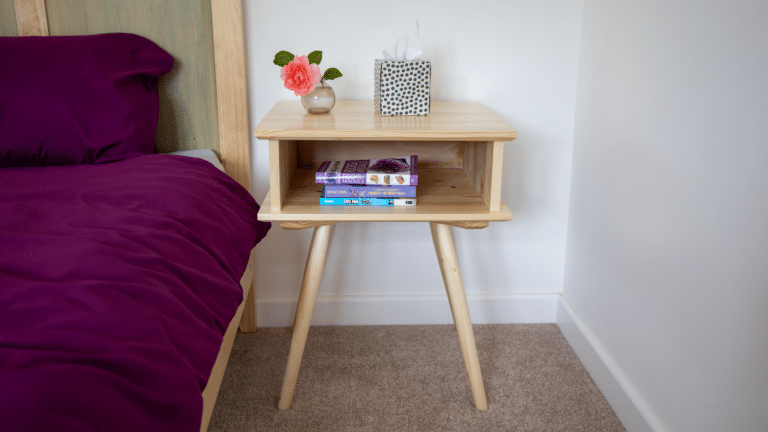

Sellers home Bedside Table: Episode 2

With the rough boards planed and laminated into panels, we clean up the surfaces and prepare them for the joinery. Paul has a stopped and stepped housing dado to form each corner. This makes for a perfectly fitting joint, even if we have a slight variance in the thickness of the inset piece due to…