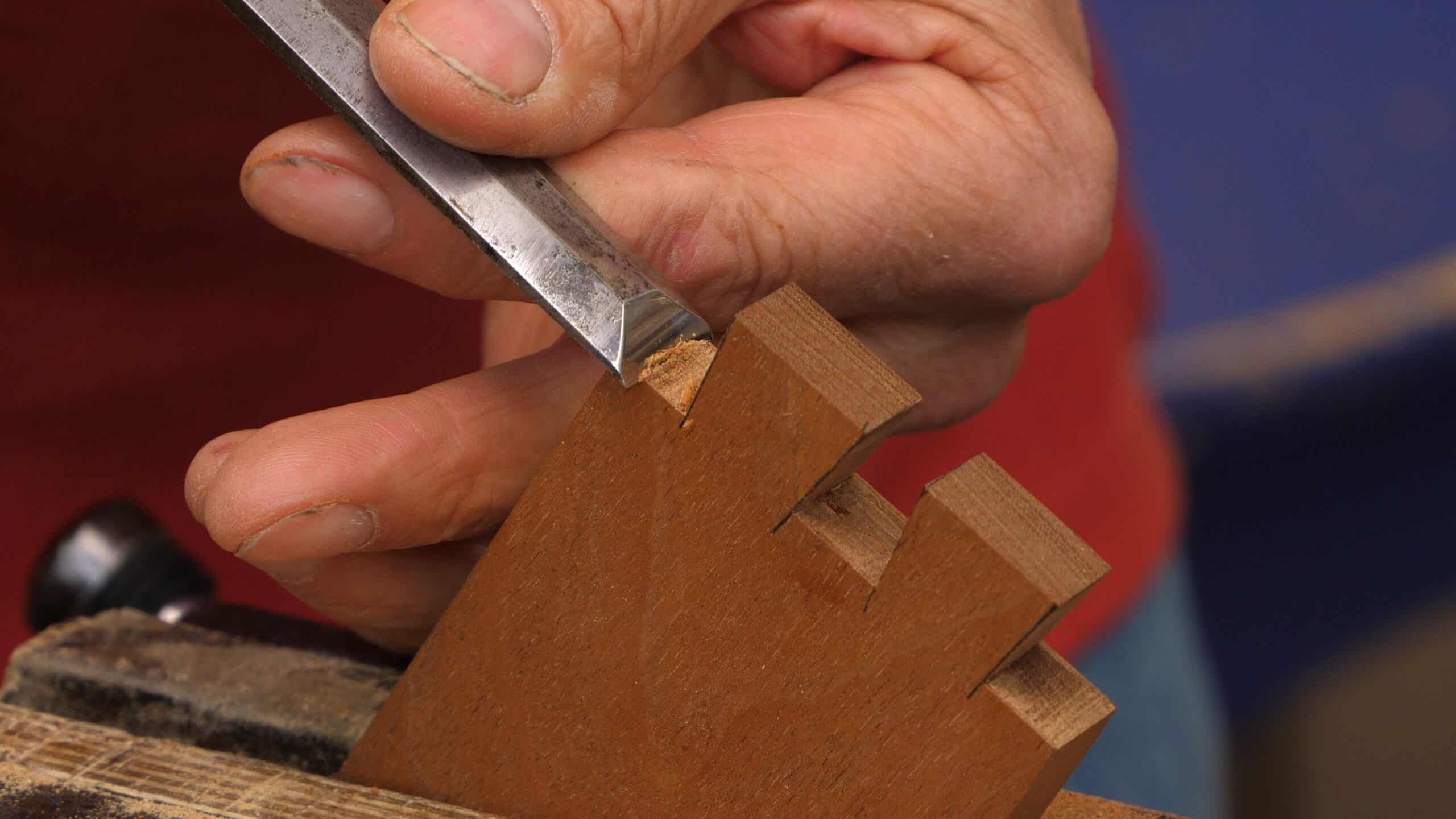

Half-Lap Dovetail

Posted 21 April 2017

This is a free video, want to watch it? Just log into the site, and you can enjoy this video and many more!

The half-lap dovetail is possibly the most common of all the dovetails used today. It is used for the front corners of drawers, and anywhere where you want to use a dovetail which is not visible from a certain viewpoint. Paul has developed a method which includes a small rebate, that helps in aligning the components to achieve the crisp definition of quality half lapped dovetails.

Paul, A verry clear video. Can’t wait to try it myself. I ordered Ashley Iles Chisels but they take a few weeks to arrive.

My biggest concern wih a dovetail is alway the size. How wide should a dovetail be, where schould i start, how many do i need.

Even the books i have don’t give me a clear awnser on this matter. Can you advise me?

Regards,

Jan Willem Kooi

Generally speaking its just a style thing, although you do of course need a minimum number to make the joint strong. I generally wouldn’t make a tail bigger than an inch so my rough guide would be 2 tails for a 3 inch drawer, 2 or 3 for a 4 inch drawer, 3 or 4 for a 5 inch drawer and so on.

Material width ÷ 3* half the material thickness= number of tails (round it to whatever please you or whatever is more appropriate, for exemple if there is a dado for a drawer bottom or where the lid will be sawn off)

You now can divide your work accordingly: the number of pins always is one more than the tails. How big you make them depends on the style you’re looking for. Very thin pins look a bit more elegant, but slightly brighter ones are much more rustic and traditional. In my school book, they propose a ration of 1:2. For exemple, if the material is 20mm thick, you draw a video line at 10mm from the edge of the tail board. If you calculated that you need 4 tails (random.number) , you than know that there are 5 pins. Since the size ratio of tails to pins is 2:1, you can separate the board width in 2*4+5= 13 equal parts (method of you choice, compass or ruler layed diagonally work fine). You than use these points to reference your dovetail layout guide or beveled gauge, knowing that a tail uses two parts while a pin only one.

You can otherwise use a compass, but not not gonna go into the details, there are plenty videos out there.

Jan Willem,

This isn’t a science i don’t think. Paull addresses it here: https://paulsellers.com/2012/03/questions-answered-dovetail-sizing/ and more recently here: https://paulsellers.com/2014/09/on-dovetails-and-sizing-just-some-thoughts-i-have/

Groetjes,

Mic

Superb precision …….thank you Paul …….John

wow, that work had me at the edge of my seat almost as if I were doing it. beautiful job

Awesome. I haven’t made half-laps yet but soon will when I make my first drawers for my shop cabinets. Loved the video. Thanks Paul.

Thank you WWMC team!

HI Paul and the team ,thanks for a great video ,have just seen where i have been going wrong

thanks again .take care .

Absolutely marvelous.Thanks Paul.

What a pleasure it is to watch you work! As I have said before your craftsmanship makes me want to do better. Thanks again Paul, your the best.

I always enjoy watching you work. It reminds me to be patient with the wood and the results will tell the story. Great video.

Just finishing a trestle table and used dovetail joints on the supporting skirt. This has been very useful and nicely detailed. I really value your demonstrations – once again, very warm thanks, this is a great kindness.

Dave

Nice work…

Could you tell me what kind of wood you used in this video?

Seeing the grain direction is important to chisel out the wastes.

Thank you, Paul.

Sapele also called sapele mahogany (also spelt sapelli, sapeli)

To the video team…… love the fantastic close ups. Thumbs up!!

Great demo Paul. Thanks for sharing.

Beautiful.

I gasped when the grain started splitting on the dovetail. Then cool as can be Paul flips it around and approaches from the other direction.

Hi Paul – How can I find that same router plane or at least that router cutter, or one of comparable size and shape, to fit my Stanley 71?

Thanks!

Well that was a quick search, and I will answer my own question. This is the Veritas Router plane. A very nice tool.

Paul,

Will the Veritas blade fit in a stanley 71 router plane?

-JP

Yes. Their web page says, “Our high-carbon steel router plane blades fit our Veritas Router Plane, as well as Stanley #71 router planes (with the height-adjustment nut inverted).” See http://www.leevalley.com/US/wood/page.aspx?p=52609. I’m not affiliated with them in any way.

A Reminder for the Group,

Even with the rebate/rabbet on the inside of the drawer front, I find it difficult to balance the tailboard to trace the tails on the pin board. There is a technique that Paul has demonstrated in his YouTube video “How to make a Dovetail Joint – The Three Joints” that helps you avoid the balancing act of holding the tailboard on the pinboard for marking out. I wanted to remind everyone because its so effective at allowing you to concentrate on tracing the tails instead of worrying about holding it “just so”. The technique takes advantage of gravity to help keep the board in place. I’ll describe the steps here, but watching the video will make it very plain. Paul demonstrates the technique in the video at about 17:35.

STEPS: Lay a bench plane on the benchtop, on its side, just behind the front vise. Then, place the pin board (drawer front) in the vise with the face toward your belly so that the pinboard to be marked is at the same height of the bench plane’s side (which is facing skyward). Secure the board in the vise at this height and slide the bench plane back a distance about the length of the tailboard (drawer side). What you are striving to do is place the tailboard (drawer side) that is being traced so that one end is supported on the pinboard (the drawer front) and the other end is supported on the side of the bench plane. This creates a bridge-like structure. Doing this in conjunction with Paul’s rebate method creates a situation where the tailboard can be registered easily and perfectly square to the pinboard and held in place against the rebate with minimal effort and attention. You simply place your non-dominant hand on the “bridge” to ensure the tailboard doesn’t move while you mark out the pins. I know this description makes it sound complicated, but once you see it done, you will realize its very simple and a very helpful technique. I hope this helps the community.

Hi Paul. Thanks, that makes them look a lot less daunting.

I have bought a collection of chisels through eBay and have some with an angled tip. These would appear to be ideal for those inside corners. Is that their purpose?

@madmulberry,

If it is a true skew chisel, they are often used in carving. Sometimes they are simply a standard chisel that has been sharpened out of true for a long period.

Really enjoy watching the precision and detail. Encourages me to work to a higher level. Thanks