Joiner’s Toolbox – Episode 4

Posted 14 January 2015

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

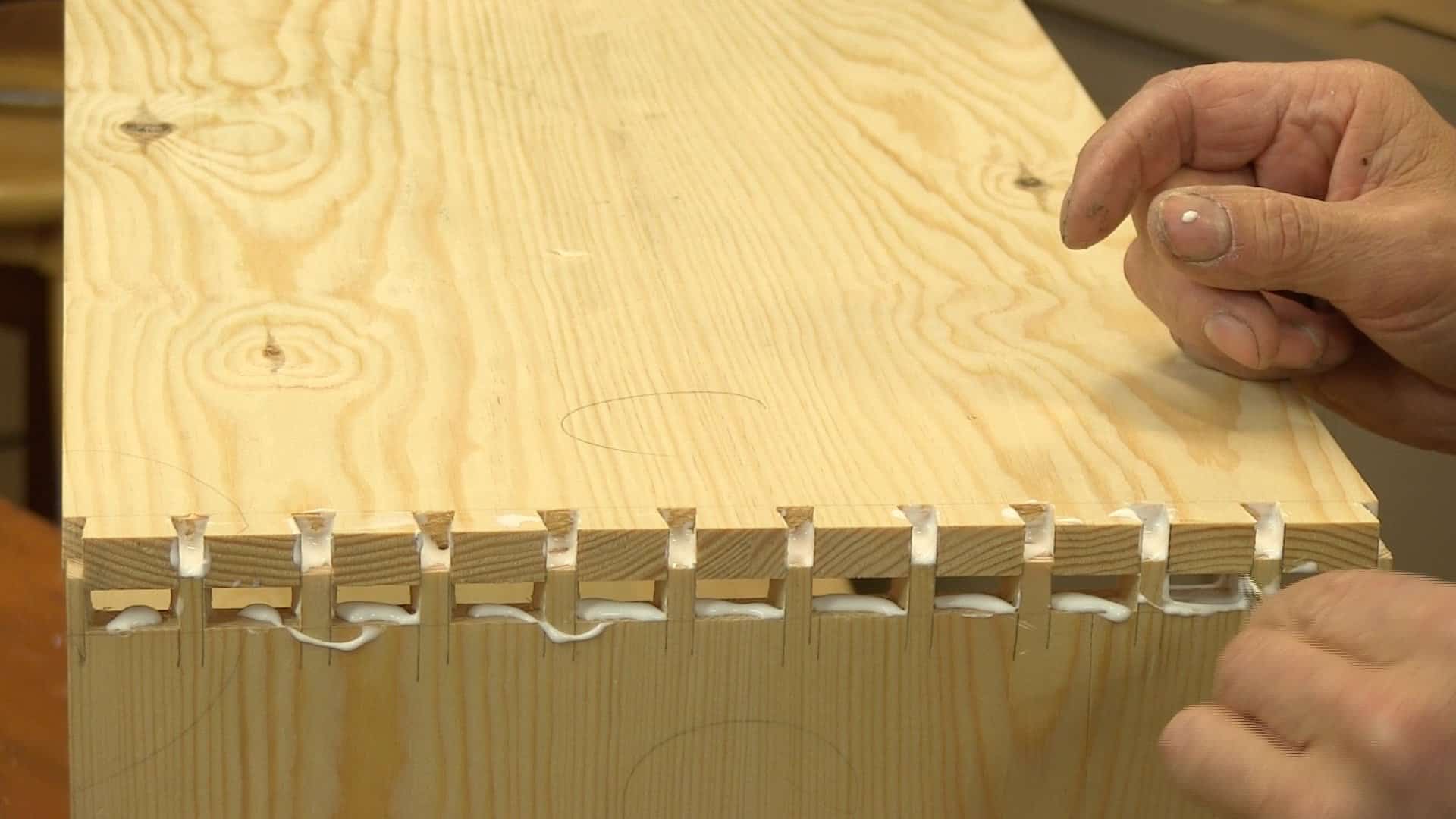

With the four corners dovetailed, it’s time to glue up the main box. Paul introduces a technique he developed to help glue up larger dovetailed boxes where there can be issues due to the fibres swelling once the glue has been applied. Once the glue has been left to set overnight, Paul cleans up the outside and edges of the box ready for the next stage.

yeah !!! I was waiting for that one – life finally is going on 🙂

Very exited about this project. Thank you for this wonderful video.

Learning mor tricks for glue ups, this is great, Thank You. I don’t own a Bullnose I will be on the look out for one.

Steve

I just finished a blanket chest, which is almost exactly the same as what you’ve done so far, but about twice the size in every dimension. So mostly I’m watching this and finding out all the things I did wrong. Or, should I say, all the little tricks that I wish I’d known beforehand. Planing the dovetails before glue up, for example. That would have made things a lot easier.

yes, you make it look easy. 😉

I would have totally broken off a pin. Paul makes his work look like a snap.

After watching Paul, I kind of cringe when I see other “celebrity woodworker”‘s dovetails (let alone my own.) Paul’s are perfect. Very impressive, every time, and a joy to watch such craftsmanship in action.

Question: Does it matter which way the dove tails are facing? (tails to front or pins to front)

It doesn’t matter which way the dovetails go in this case.

Great video, but I have to confess that I was a little disappointed when the carcass came out square in the end. I’d like to see what Paul’s method would be to fix it had it been out of square. I would enjoy seeing Paul’s ideas and processes for correcting errors also, as that is not an uncommon occurrence in the shop.

Me too. I know I learn more from my mistakes than I do from my successes.

I agree. For me, learning how to correct mistakes is as important as learning how to avoid them in the first place.

Greg, It generally is a fact that when the transfer knifewalls are dead on and the distances dead parallel then the project is pretty much guaranteed to be square too. The reason we check for squareness is because the clamps can pull the box, or frames in the case of frames, out of square and we can adjust the clamps to allow movement back to square.

Also, what we film is what you get. Generally we like it too when something goes wrong because it makes it very real and things do happen that way.

What type of glue do you use . It looks white like Elmer ?

As always a great video. Clear well explained and to the point .

Thank you

Frankj

as far as i am aware paul uses regular PVA

He does indeed.

I have no preference when it comes to PVA type. I use any I pick up except I don’t like the cheapo stuff.

A little cello tape over the cauls will keep them from adhering to the joints. A tip I learned from Mark Spagnolo

I was wondering about that!

I generally finger wipe build up before applying the cauls or pads and have never found them to stick to my work.

I hate gluing up. I recently did the carcass of a simple wall cabinet that went together beautifully in the dry run. As soon as glue touched the parts, it all went wrong. I got pieces mixed up because I hadn’t marked them properly (I know). Then the clamps pulled the whole thing out of square and I was messing about for ages to correct it. I got there in the end but I really fell out with the project that evening. As other have said, I was disappointed when Paul’s box was square! How would he correct it?

i have seen him use his clamps to pull one side into square and also you could shock the longer side in with a blow of a mallet ,having said that i have at times clamped up a project out off square because i didn’t have my clamp pressure running parallel with the project .it could start dead square but incorrect alignment of clamps can pull it off.i also find to gradually increase pressure equally on all clamps helps.

Glue freeze is something I always anticipate as a potential problem and combination of hammer blows (on a block) alongside tightening the clamp at the same time has always addressed the problem.

I’ve found glue freeze to be a real problem pretty much every time I glue up a project (I am probably not being efficient enough!)

Are there any glues that dry SLOWER than normal wood glue? I know animal hide glue does, but that seems like quite a faff. Are there any others available? Quick drying glue seems like a good idea in many walks of life, but when gluing up a big project, I want it to dry slower and give me a chance to correct!!!

I have used Lee Valley glue for such things – dries a bit slower and to a browner colour. Also seems to gap fil a bit as well

Liquid hide glue made by titebond has a very long open time and allows easier assembly for complex glue ups .

I’ve learned a technique from episode #4. Thanks!

I made a box like this 30 years ago using but joints and finishing nails. A toy box for my daughter. I had neither the training nor tools do this the “proper” way back then. It is a wonderful thing that Paul is sharing his knowledge and craft with generations of woodworkers to come. And also happy I can still learn new things before my time on this earth is over.

That box is just as solid as the day I finished it. FWIW.