Mortising without a Guide

Posted 31 August 2015

This is a free video, want to watch it? Just log into the site, and you can enjoy this video and many more!

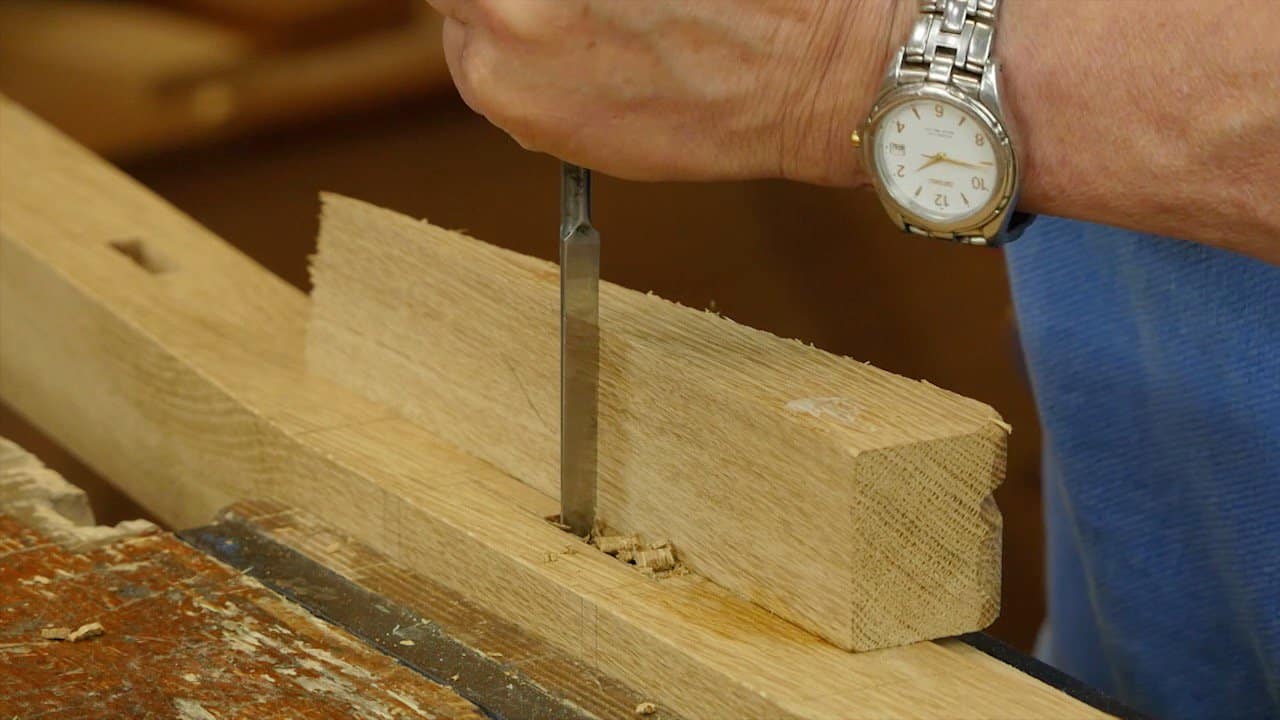

Paul shows a few ways to temporarily attach a guide block to help keep your chisel square when chopping a mortise. This is particularly useful when you don’t have a guide made or a flat surface to register the guide against or are only chopping a few mortises.

Thanks for the video!

Easy and simple as usually!

🙂

Very helpful, thanks. I noticed I tended to wander a bit left and right along the length of the mortise, this helps keep things nice and straight.

One other issue I’ve had is that as I chop my chisel sometimes starts perpendicular to the length of the mortise but as I go deeper the chisel ends up angled within the hole. The chisel stays within the area laid out for it but twisted within the mortise at about 10 degrees. The end result is that I don’t chop out the entire width of the mortise unless I make a second pass. Any suggestions on how to prevent this? Grip the chisel more firmly? Take less waste with each cut?

You might be hitting too hard, that is too aggressively. Try taking a more gentle approach. If your chisel is sharp, it should not take much to penetrate the wood, and you will retain more control of your chisel. I find control is the key, that is you being in control of the tools and the wood.

Thanks – very helpful

Very helpful and simple. No clue why I didn’t think of it before. Forest fore the trees.

Thanks a lot Mr. Sellers for this fine artwork-tipps. And for shure you love wood, we all do!

It happens often to me that the mortise is not square to the surface of the wood. Then when I assemble the Tenon into the mortise, it leaves a gap between the shoulder and the mortised piece. I can only make square mortises with the help of pre-made guides, or this one which is faster. Im not happy to still be dependent of the use of such things.

Elsewhere, Paul mentioned “hide glue” you can buy premade in a bottle, which you use cold. Does that stuff really release when struck? Would it be suitable here for the temporary guide blocks, or is it too permanent or too slow to bond?

You can crack the glue line with a chisel if you are careful, but it does not “release”. I doubt it would be suitable for this application since it also does a very good job of holding the chair to together.

Very helpful; thank you Paul! That guide block concept is so very useful in so many situations, and quite preferable to being dependent on a screaming router, imho. Robert from Indiana.