Sizing Dovetails

Posted 19 January 2018

This is a free video, want to watch it? Just log into the site, and you can enjoy this video and many more!

Dovetail sizing has a big effect on the strength and appearance of your project. Paul shares some advice on how to size your dovetails depending on the size of your project.

Read more about dovetail sizing on Paul’s Blog here.

It is amazing how much I learned from this video; not just dovetail layout, but how to drag a finger on edge to make a straight line, and use the power of the hypotenuse to divide in equal parts. Why shouldn’t I already know this? No, I waste time working fractions on a straight line and double marking to form straight lines with a straightedge. That’s what makes you the master of the Masterclass (I would say “Master,” but there is but one Master to me). Thanks, Paul!

Agreed; one of the implied lessons I’ve been learning from watching traditionally trained woodworkers is that good enough really is good enough. You can measure things to the millimeter, and sometimes that matters, but for many things the precise position or size is less important than that the corresponding piece(s) are in agreement with each other, and “showing the wood to the wood” combined with undercutting and trimming to match achieves that more directly and reliably. The goal, after all, is to build something that pleases the eye and will last, without wasted effort. Some day I may get there…

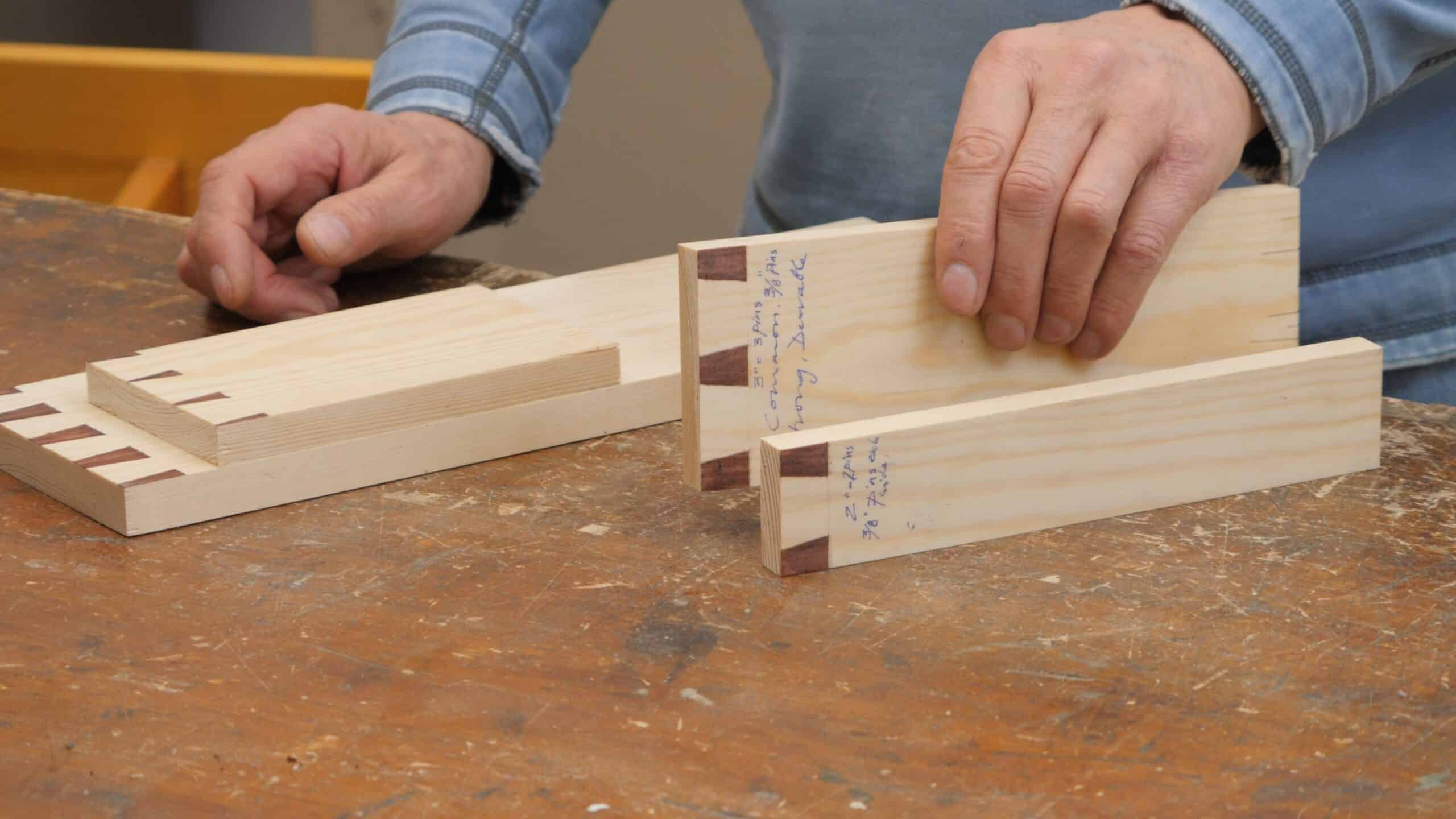

Your demonstration of how to lay out dovetails stopped me from buying a dovetail jig at a woodworking show in 2012. You had the dovetails done (and dusted) while they were still trying to set up the jig. I really like your samples, I may just make some for myself and write notes on them so I can recall what I’m supposed to do.

Samples can be thought of as another kind of template or story stick, even if you don’t follow them exactly. Good thought.

Thank you for the excellent video, makes layout a breeze eliminates the awkward math.

Simple and effective makes for a good prescription!!

Excellent video like always you make your videos easy to do things. Thank you for your great teachings. It is a great way to learn from your experience that most people would never get.

I appreciate the rule of thumb for dovetails per inch. I try to make the tails narrow enough so no one can mistake them for machine made but not so narrow that they are weak and no smaller than my narrowest chisel. This layout method is interesting, but I like the divider method.

Excellent video, as always. Thank you! Very timely information for me and great video work.

That was the simplest dovetail layout I have seen. Thanks

This is a very straightforward and useful approach to dovetail layout, a task that many seem to turn into a bit of drama. No need for that.

Very good video. Thank you.

Lovely. My math teacher called and said this is way easier than a calculator.

Very simple way to get the same results as a divider.

Sad joke here:

“Greene and Greene called and said to stop giving away the old secrets”

They didn’t typicaly use this type of joint, that I can see.

You’ve mentioned it before that something simple like this would have been a trade secret. Time is always money and a valuable asset would be shortcuts like this.

Great video, as always! I like the no fuss approach. It bugs me when I see people taking ages to lay out dovetails with dividers. Those same people are usually the ones using feeler gauges and digital calipers as well.

On the contrary – the divider method takes literally seconds to lay out any size of dovetail. Paul’s method is fine, but it certainly isn’t the quickest or the most accurate, in my experience.

Absolutely great! This very succinct lesson truly epitomizes Woodworking Masterclasses — lessons taught by a true woodworking master (i.e., one who has put in the time necessary to develop the pre-requisite hand, eye, skill set(s), and experiences that are coupled with a passion to teach and train others, thereby duplicating themselves as a lifetime investment for a future generation). This one lesson has been worth it all …! We are indeed indebted to you, Master Paul, and Staff. Thank you.

Thank you very much for this video. It is very helpful. I have a question I think it is time to ask. Why do you always use a half PIN on the outside of the board and never a half TAIL? Is there a reason or is it your preference?

Thank you very much

Ted

Hi Ted. You can use a half tail if you want. No particular reason not to, but it has never been accepted practice.

Interesting

Great video Paul. It’s a very simple layout procedure that’s easy to understand and it works every time. I only wish sawing the darned things was as easy!

Thanks Paul, will be a great help. Details to be included in your next book I hope?

Neil.

Another great video and simple “rules”

That 3″ looks more like 4″ to me it looks double the height of the 2″ stock, it is not important since the method still works.

Most of my life I worked with steel and iron, I had a number of hangups swapping to wood.

I like what you do and how you explain everything.

all the best

John

I think Paul can work in any measurement system as they are all arbitrary. 1/2, 1/4, 1/8th of any measurement system be it 1/2, 1/4 or 1/8 cm, in, bu, does not matter. Math is not arbitrary, fractions exist in every number system and they are pure real numbers, whereas a decimal is a mental crutch. 0.5, 0.25, 0.125 (system dependant) and is a fraction without a denominator. In the U.S. we teach metric in school and use the NIST definitions for inch, pound, foot, mile, cup tablespoon, etc in everyday life, Machine language is not metric or imperial but is a base 2 number system. 1011 = 13, seen as a block of 1, no block of 2, a block of 4 and a block of 8, so the machine sees the phrase as; yes, no, yes, yes! Love fractions and use your system of choice. Math is our best friend. Like football, we can’t understand it until we know the rules and symbols. How does one say half a glass of water in metric? Paul makes it all so simple! This is a really great video and will become famous for its balanced simplicity, creativity regardless of our prefered number system!

“1011 = 13, seen as a block of 1, no block of 2, a block of 4 and a block of 8, so the machine sees the phrase as; yes, no, yes, yes!”

Actually, the correct binary notation for 13 is 1101.

Higher powers on the left, just like decimal.

My speed error

Sizing of dovetails, good to know. I generally take a few minutes (30 minutes or so) to work this out before cutting. Having a system will be very helpful. Thank you.

I was looking at the shelf in the background, will you be making this in the near future? I’ve been looking to make a shelf and decided a couple of weeks ago that this design would go well in my office. Seeing it in your video was timely (if you’re going to post a video on the build) in that I wouldn’t have to design it myself (although I would very well have to “tweak” the design).

The shelf in on it’s way.

Best, Phil

Great – I’d love to see it too! Nick

A super easy way to divided any width board into equal parts. I remember learning this technique in my technical drawing classes, (dividing any length line into equal length sections) but never thought of applying it to marking out positions of dovetails. Thank you Paul, this will prove very useful.

Thank you for the simplicity in laying out the dovetails. Now we get to cut.

Divider method is simply elegant. Thank you for sharing.

Nice lesson .wwmc should do more of these extremely help videos

Thanks,

David

Thank You Paul…..

So ,the rule I have learnt is one less dovetail than the number of inches width of the boards .Yes ,thats simple to remember.

I am wondering if there is a reason Paul does not use the divider (aka compass) method developed by Alan Peters. It seems simpler to me than needing to draw all the lines and make all the measurements of the system displayed here. However, I have already learned that Paul’s methods are typically better than others, often based on some consideration that is beyond my level of skill of understanding. I would love to know if that is the case again here, making his system inherently better than Alan’s. I will be grateful for any response to this. Thank you.

I am new to woodworking and this explanation is the best (and simplest) I have found about dovetail layout. All of Pauls videos are excellent. Clear and logically presented. Thank you for sharing you vast knowledge and experience.

remarkable.

Ah. I had learned this as a kid from my grandfather, but not having used it in many, many years, forgotten the exact details. Thank you so much for jogging my ailing memory. Now I can bookmark this. If I could only bookmark my grandfathers.

i am slower than a slug, i am going to have to watch it again, here i go!!