Chest of Drawers: Episode 15

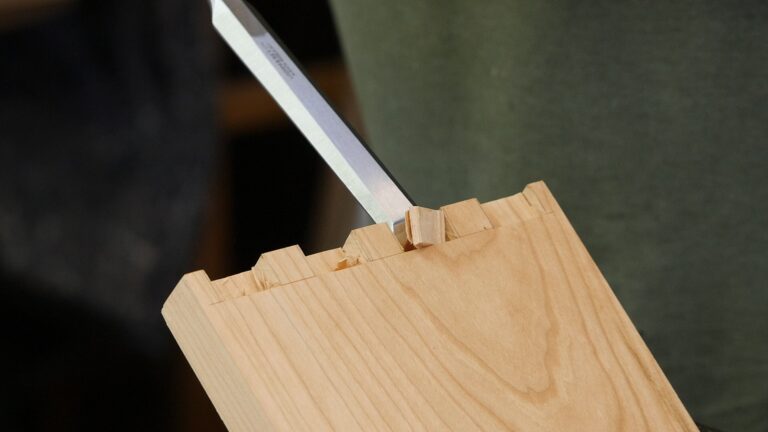

Once the drawers have been checked for fit, they are ready to glue up. The sequence and other essential details are clearly shown to ensure a smooth process. Once the drawer bottom is in place, the drawers can be carefully fit to the carcass and finessed. With that complete, including some drawer stops, the chest and drawers are ready for some shellac.