Bench Stool: Episode 3

Posted 11 December 2013

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

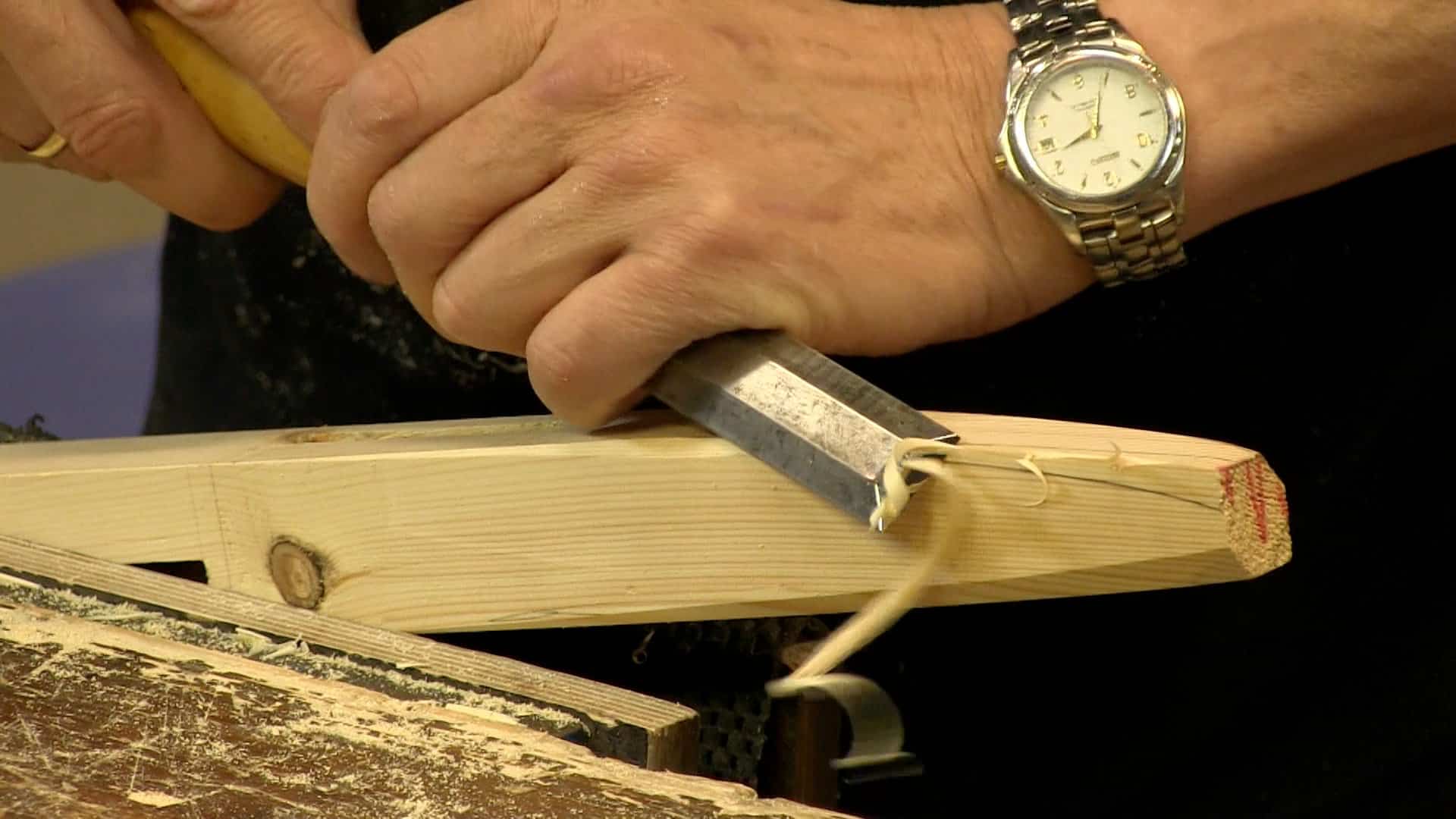

In this episode, Paul shows us how to cut the angled rails to length using the template and the sliding bevel. He then shows some different methods for cutting and fitting the tenons, and cuts the legs to length.

Nice job guys, thanks for this one 😉

Waiting for this since last Monday. I’m particularly interested in the shaping techniques. Thank you Paul and team.

Who makes the spoke shave Paul is using? And what grit of sandpaper is Paul using for his final light sanding?

Denise, Joseph made the spoke shave. Paul generally finishes with 220/240 grit

Oh no, I’d love a spoke shave like that that has adjustment screws. Ken, thank you for your answers to my questions. I need a box for sandpaper like the one Paul made and uses.

The spoke shave that Joseph made is a very nice copy of the Stanley #151. Look for a vintage one.

I posted a drawing set for the sandpaper caddy and another post for a jig to quarter standard sheets of sandpaper so they fit into it.

https://woodworkingmasterclasses.com/discussions/topic/sandpaper-storagedispenser-box-build/

https://woodworkingmasterclasses.com/discussions/topic/sandpaper-quartering-jig-build/

Denise, A record 0151 or stanley 151 spokeshave is what you desire. The 51’s don’t have the adjustment screws. But Paul often sets his uneven with a heavy bite on one side and a lite cut on the other so the adjustment screws are not critical.

Hey guys, as Joseph has said, please keep the project threads on topic.

HaHa the tool forum is this way………..https://woodworkingmasterclasses.com/discussions/forums/general-woodworking-discussions/tools-and-tool-maintenancerestoration/

Cheers 😉

Denise,

http://www.lie-nielsen.com/spokeshaves/boggs-spokeshaves/

or

http://www.woodcraft.com/Product/2005130/5715/Flat-Face-Spokeshave.aspx

or

http://www.woodcraft.com/Product/2084949/35604/Pinnacle-No-151-Spokeshave.aspx

or what you really are after:

http://www.mobergtools.com/spokeshave.html

Best,

Craig

Craig,

Thanks for the tip on Moberg. I bought one today.

This is exciting I am chopping at the bit to start making one of these, great job Paul and crew. Paul you make it look so easy using the bare minimum for tools, I love it. And I can also tell you I hate sanding especially with my allergies and sinus problems, sand as you go I’m in.

Thanks again !

Steve

looking forward to this build and the techniques involved thanks team .

TGIW !!!!!!

Craig

I like how this builds on the coffee table leg by taking it to the next level with angles/work on all four sides.

Thanks WWMC.

Nice one Paul and team 😉

I’m going to be a convert to Paul’s sharpening method after all I think. Even my best job doesn’t cut nearly as sweetly as his. Watching a simple tool like the chisel form those shapes reveals some true skill. Really enjoyed this one, thanks.

Great episode. Can’t wait to build this one.

Paul,

You state, while shaping the legs, that “It’s a bench stool, and who’s going to care?” I think everyone cares, because it isn’t about making a bench stool.

One very important lesson I took home from New York is that it’s not about making a project. It’s about making perfect joinery. If you succeed at that, you have a really nice project, but you can take the lessons and apply them to anything. A kitchen stool, a chair, an end table, whatever. The lesson remains the same, and a great looking leg is the result.

I learn a lot from you each week and miss working near you and my other classmates. John and I were just saying how much we want to return.

God bless you.

David

David,

I believe you missed Paul’s follow-on comment at 29:12….it was straight to the heart of WWMC. It also revealed his true sense of craftsmanship (once again.)

I envy your time with Paul in New York and hope you get another opportunity to return.

Regards,

John

I didn’t miss the comment. You may or may not want to use this detail on a bench stool, but the bench stool isn’t the important part. The important part is you’re learning a leg detail that is elegant, refined, and beautiful, that will work on any project you choose. You just happen to be learning this detail on a bench stool. The project isn’t the key. The key is the joinery, detailing, finishing, etc. being passed on to all of us.

In class, the joiners tool chest was our first project. Day after day Paul said “Forget about the project and concentrate on the joinery lessons.” That project in particular, is chocked full of joinery lessons. As I watch each episode from WWMC, I appreciate the lessons, which can be applied to any project I choose.

I’m not sure what part of the world you’re in John, and this goes for everyone, but if you ever can make it to a class with Paul, do it. What ever it takes to make happen, it is well worth it. I struggled a lot to go. Tuition, housing, food, travel, 5 weeks of lost wages, missing my children, etc., etc. I don’t regret it for 1 minute, and would do it again in a heartbeat. I left with 3 projects, worth well more than the cost of tuition, that I built, along with the knowledge, and 10 new friends, whom I miss very much.

If Mr. Sellers struggles to find the right angle for a round bottom spokeshave, you can rest assured that my butt ain’t about to try to figure it out…

I really loved the details of the leg and how it was done. Little things, but it really makes a big difference in the look.