Breadboard-end Cutting Board: Episode 5

Posted 10 July 2013

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

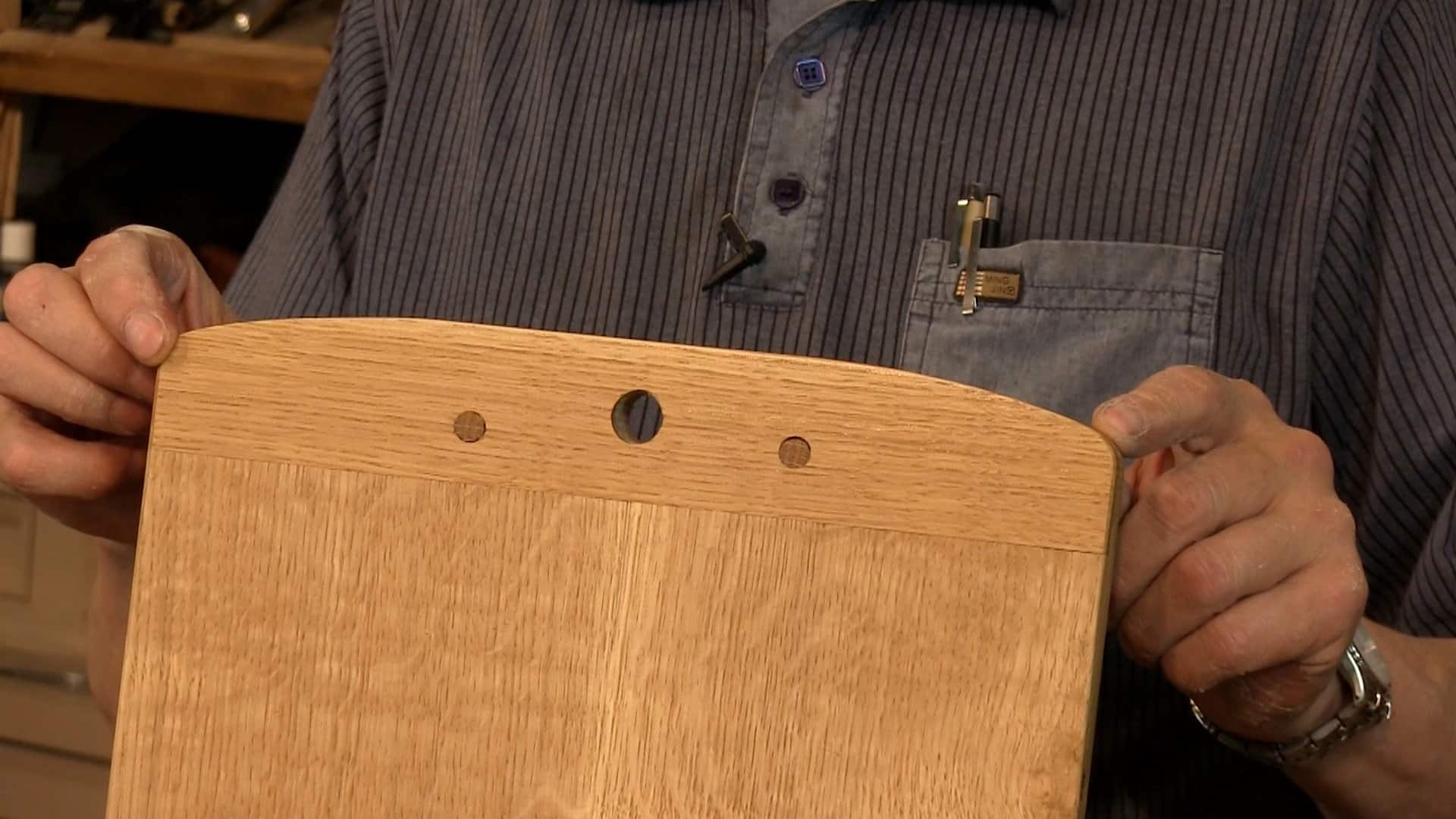

This is the final episode for this project. Paul shows how to use the pegs in offset holes to hold the joint. This is a great ‘clampless’ method of joinery which is great for creating stable table tops as well as cutting boards.

Great job guys, thanks for this one

I made this board from Hard Maple. I made two mistakes. The first one, I did not put enough of a bevel on the ends of the pegs. The second, I did not check after driving the first one. So, as it turned out I blew out the holes with the pegs on both holes. The other end turned out well.

I found that this video answered a few questions I had about frame and panel doors. 1) how to trim the stiles to fit the final frame and 2) how to draw bore the tenons in the frame. As usual the Sellers method is very simple and very clever. Thanks

Wonderful series! Thanks.

“It will bleed” hahahahaaa.

Definitely on the project list. Would you consider drilling the back side hole 1/16 smaller to accommodate the fact that the dowels compress so much?

Thanks.

… and Done!

Beautiful. I think it’s time my family had a new cutting board 🙂

Beautiful work Paul. I just finished a small cutting board out of oak. You are the only person I could find online using oak for cutting boards. I haven’t used it yet because I want to season it first, but I didn’t have any food grade finish on hand. Thanks to you, now I’m going to use vegetable oil, and see if it goes rancid or not. Thanks again for all you do, keep up the great work.

Another great video, and this looks like a fun project to make as well.

Steve

Another project to think about

Well done.

Thank you for this series. I made a cutting board out of maple with cherry edges, that will be a wedding gift. I enjoyed this project and was able to use a cabinet scraper properly for the first time. Using Paul’s discussion in his blog coupled with the use in this video I now have experienced what a valuable tool it is. I was wondering if Paul would recommend easing the edges of a new Veritas cabinet scraper as he discussed with the smoothing plane earlier this week?

Have you every performed a drawbore in 2 dimensions inorder to pull 2 joint seams together at one time?

Loved this series! But only one drawback…everyone now wants one!

(Three down…three more to go)

Paul,

If you were building a wider table top using this method, would you do it with multiple sections gluing them together in the same manner as you did with the two panels of the cutting board?

Yes, but this time I would likely hide the tenons inside the breadboard ends so that they stop shy of the outside by say 1/2″ depending on the width of those ends. I would then leave space either side of the tenon to allow movement either side. the middle one would be fixed and immoveable, the next say a gap 1/8″ either side, the next 3/16″ and the last one say 1/4″. This works well!

Thanks Paul, it makes a lot of sense and provides the flexibility for fitting multiple boards.

Hello Paul, how would you address the drawbore pins? Would you slot the holes in the tenon to allow movement? Any guidance would be great.

Ryan

Hello Ryan, are you referring to wider tops. If so, Paul would indeed recommend elongating or slotting the holes in the tenon to allow movement.

In the event someone comes across these comments and isn’t already aware, Paul has a more recent blog article on this:

https://paulsellers.com/2017/03/breadboard-ends-draw-bore-pins/

Thanks very much for that link! I missed it, and it really makes this clear.

Paul:

What about scrubbing the cutting board with hot water and dish detergent?

If you fry it right away, have been doing this for 60+ years with no ill effects. Just don’t soak while catching a movie

Dry ,dry ! spellcheck gets me again!

Lovely board! I have some oak that will be perfect for this one. And, I too, have never had a problem with the vegetable oil going rancid. Well done!

I think it’s good you left the parts in where you had a bit of unexpectedness ( I heard you mention you didn’t know if you should put it in the video) Personally I was glad you did because for us newbies at least we know how a master craftsman would handle those situations and move on. So when it happens to any of us at least we know a few solutions now.

I totally agree with raven, these mishaps and struggles that are shown are very helpful when starting out in this work/art. I find so much information in the parts that don’t go 100% perfect, this is real life, things go wrong. Thanks for all the help through good and bad.

Is it just my eyes, or is the hole on the right side a tiny bit……

Walnut Oil, the kind used in salad dressing, will polymerize (harden) and not go rancid. Those people who suffer Peanut allergies may want to avoid it, but for most people it works nicely and is commonly used for bowls and spoons.

Wondering a few things?

Why didn’t you burry the knot in the glue joint?

You said you would rip 1/4″ off the other side to make the board symmetrical and didn’t do it?

This looks like an old video, why replay now?

Thanks, JIM

Jim- wood has knots, working with them rather than cutting out shows character and grain, which to many are far more pretty than straight. The quarter inch left on one side is negligible and most likely would not be seen by any one that had not made the item. The content is from an earlier date, but still valid shown by the many appreciated comments above. Plain plastic cutting boards are everywhere, but one made by a craftsman for the family is a work of art to cherish.

Lovely board, and on my project list. I agree with Bill about Walnut Oil. I have used it for several years on hand carved wooden bowls, and it will not go rancid. Also in the past two years I have started using Butcher Block Oil on anything food relayed and like it better than the Walnut Oil. Used the Butcher Block Oil on a cutting board and two more bowels I made for my wife for Christmas. She wanted a smaller cutting board so was a slightly different design, but turned out beautiful.

Great job, Thanks