Making Wooden Wall Brackets: Episode 1

Posted 15 June 2016

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

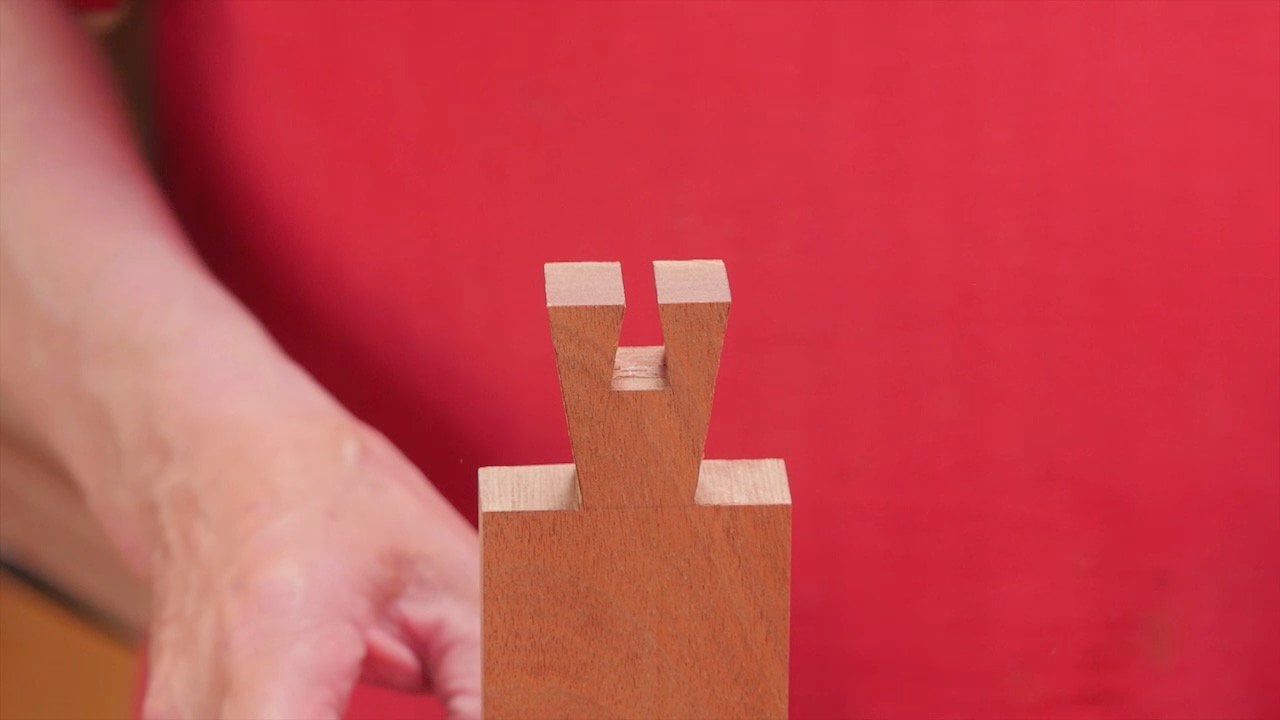

Accuracy is essential to making this wall bracket, so Paul has hand planed the stock to exact parameters. He then uses a storyboard to layout the bracket, starting with the dovetailed corner. Once the houndstooth tail is cut, Paul transfers the layout and cuts the recess, with a backer to ensure accurate cutting.

Hi all-

Looks like another interesting project.

But, I couldn’t see anything on the planning board. Perhaps remark the lines with a thin point Sharpie.

— Steve.

I agree it was kind of hard to see on the drawing board. Be sure to get the PDF file on the “Project Info” page though. It shows the diagrams in beautiful detail.

This is a substantial bracket for sure, I have never cut a “houndstooth” Dove Tail before. I have just the application for a couple of these brackets out in my shop.

Looking forward to the finished project, thanks Paul and team for another great project.

Steve

Isn’t that two half pins and one whole pin making it two dovetails? I’m asking a question . I suppose it doesn’t really matter that much . I do like the project though. This bracket is essential in a woodworking shop I would think . I probably could make one like this after going through 200 bf. of lumber lol, “Probably. I’m sorry but I can’t help myself. I have to be joking all the time. Thanks for the project I do like it. A lot.

I was just thinking to myself yesterday how nice it would be to have a video that focuses on the Houndstooth dovetail joint. Great video.

Thank you. One of my favourite lessons yet. This attention to to accurate layout on the wood itself seems to me to be one of the big differentiating factors between seeing real artisanal skill with a heritage of hundreds of years (with Paul providing half of one of those hundreds), and seeing industrial methods translocated at great expense to home wood workers feeling obliged to become machinists.

It exemplifies what I love about WWMC.

Also I have a caseless pendulum clock mechanism (a comtoise) that will one day sit on a shelf with brackets like these.

I am going to build a set of these for a friend in New York City to use as a bicycle hanger in his apartment. I think I will modify the end of the top rail by adding a additional block that can be fitted to the top tube of the bicycle and then lined with felt to protect the finish on his bike. Thanks for the great idea!

–mike–

Mike-

If you do this, but a topic in the project forum on it. Assuming it works to plan, I might have to do it for my bikes.

Thank you for the lesson.

Thank you for this. Others may have already mentioned this, but feel worth noting that section with layout was not at all visible due to use of pencil instead of ink.

Hi Markus, thanks for noting that, we will work on it.

any reason to not use say a 1/4″ draw pin through the tenon on the brace instead of the screws?

No, you could use draw bore method.

What does getting your saw square to the piece mean? Vertical at a perpendicular angle to the workpiece? Paul often drops his hand to gain more power to the saw stroke. What is the purpose of getting the saw square if you angle the blade of the saw later?

Hello Justin,

Square to the piece, means that the cut is exactly in line with the knife wall or pencil line, so at exactly 90 degrees to the wood. Paul drops his hand to help keep inline with the cut and/or to enable small adjustments to stay in line.