Sellers Home Dining Table: Episode 6

Posted 2 March 2022

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

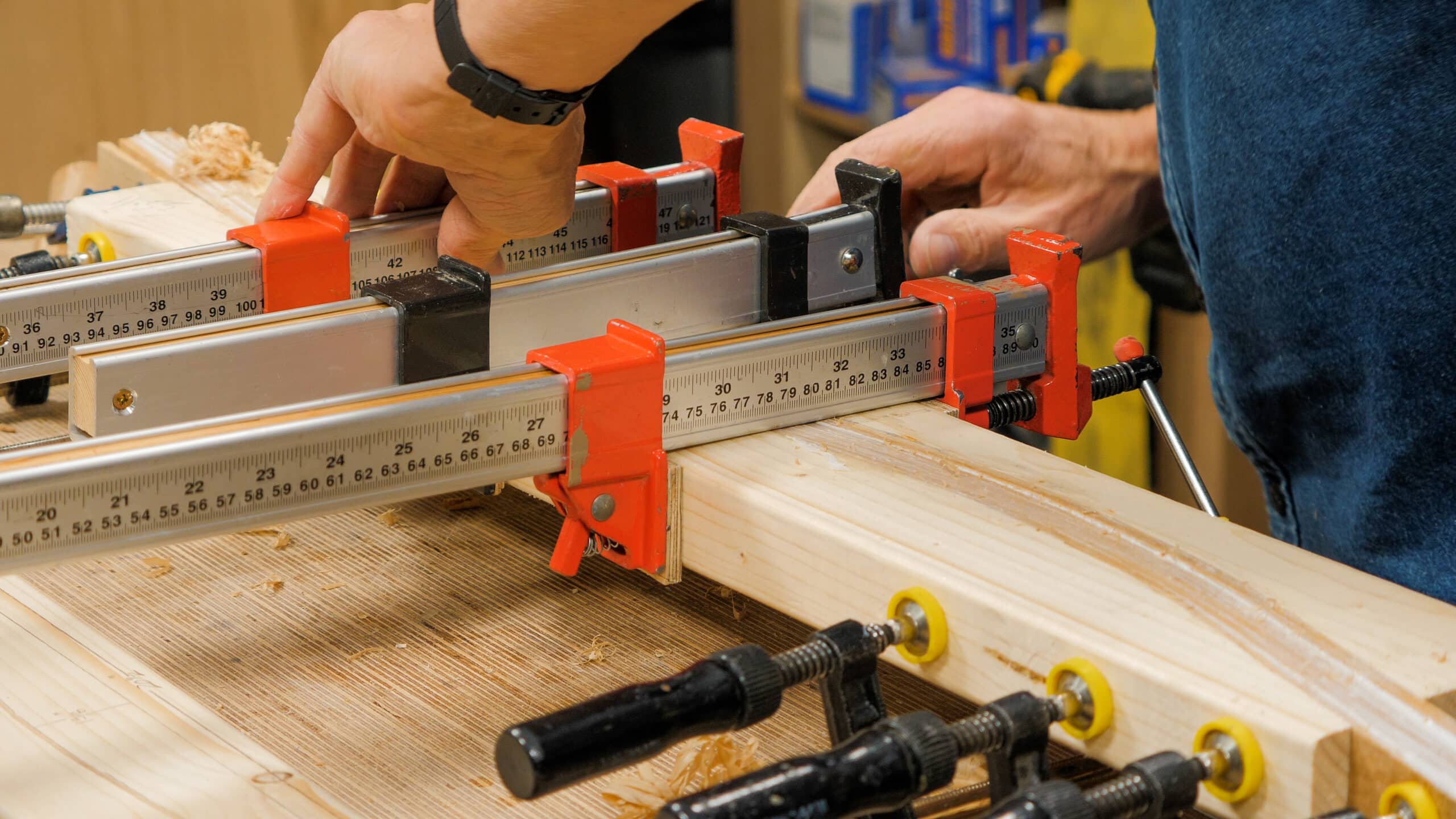

So many trade secrets and solutions to difficult problems throughout this episode, surrounding grain, leveling, and truing tabletops. It’s not too often you get to follow a whole tabletop this size being trued up with planes only, and Paul used a variety of planes to do this. These are methods Paul has developed alongside the use of his poor-man’s scrub planes in a converted #4 smoothing plane and #78 rebate plane for scrub-plane work. We switch to creating the hitherto unseen bracing method Paul developed for this dining table in preparation for the rarely used fox-wedging technique as a fixed anchor for the corners. We hope this is enjoyable for you.

Congratulations to you and your family on the birth of a Great Grandson!

Secondly, you showed me a great way to shape/ bend wood without getting into a steaming system.

Congrats and thanks again!

Congrats! 🙂

It looked like a good amount of work on the top after glue-up. So much so that it made me wonder about the merit of not prepping the individual pieces quite so carefully, given that they moved after prep. I suppose I’m asking whether you would ever only prepare the jointing edges, then glue up, and then do the face sides as part of the table top. Would that save time, or cause a load of problems I’ve not considered? Thanks.

I asked Paul and he said it would cause problems and you wouldn’t save time. You would need to ensure that the boards aren’t twisted before you glued up otherwise your table top would be twisted.

Another great episode. Having flattened my fair share of table tops (and bench tops) by hand I have a couple questions:

1) Does Paul ever consider the grain direction when gluing up the top? While having all the grain going the same direction for each board would be beneficial for future flattening, I feel like it can impact the aesthetics. Does Paul prioritize aesthetics over workability when faced with the decision?

2) Does Paul see any utility in using an even longer plane (#7 or 8) to get a super flat top? I often wonder “how flat is flat enough?” and when do you reach the point of diminishing returns.

Thanks again all!

I asked Paul and his reply is below:

1 I usually choose my face grain according to how each separate board compliments the table as a whole. I never consider alternating boards according to the radius of the growth rings of the grain.

2. Never ever, ever number 7 or 8 does not create a super flat top any more than a 5 or 5 ½. How flat is flat and of course the assumption that will stay flat is a completely false assumption as wood regularly moves according to exchanges of humidity levels.

I started watching this wondering how Paul would make sure the table top was out of twist once assembled since it’s wider than most winding sticks, but then never saw him address that. Is that not a concern thanks to careful preparation of the boards before glue up? Or is it that the weight of the large top will pull itself out of twist when laid over the level frame of the aprons? Or do you just not worry about flatness so much as worrying that all of the localized undulations are smoothed out? Thanks!

Wanted to ask, what do you call the really large that square that Paul uses to square up the ends? Do they usually come with those brass pieces to register them against the ends or do you need to buy those separately?

*really large square that Paul uses*

Thats a framing square and the brass bolts are separate and usually are used for stairs. This is the first time i I have seen one used for squaring. Makes perfect sense they keep the square on the boards. Better than tipping the square edge.