Breadboard-end Cutting Board: Episode 2

Posted 19 June 2013

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

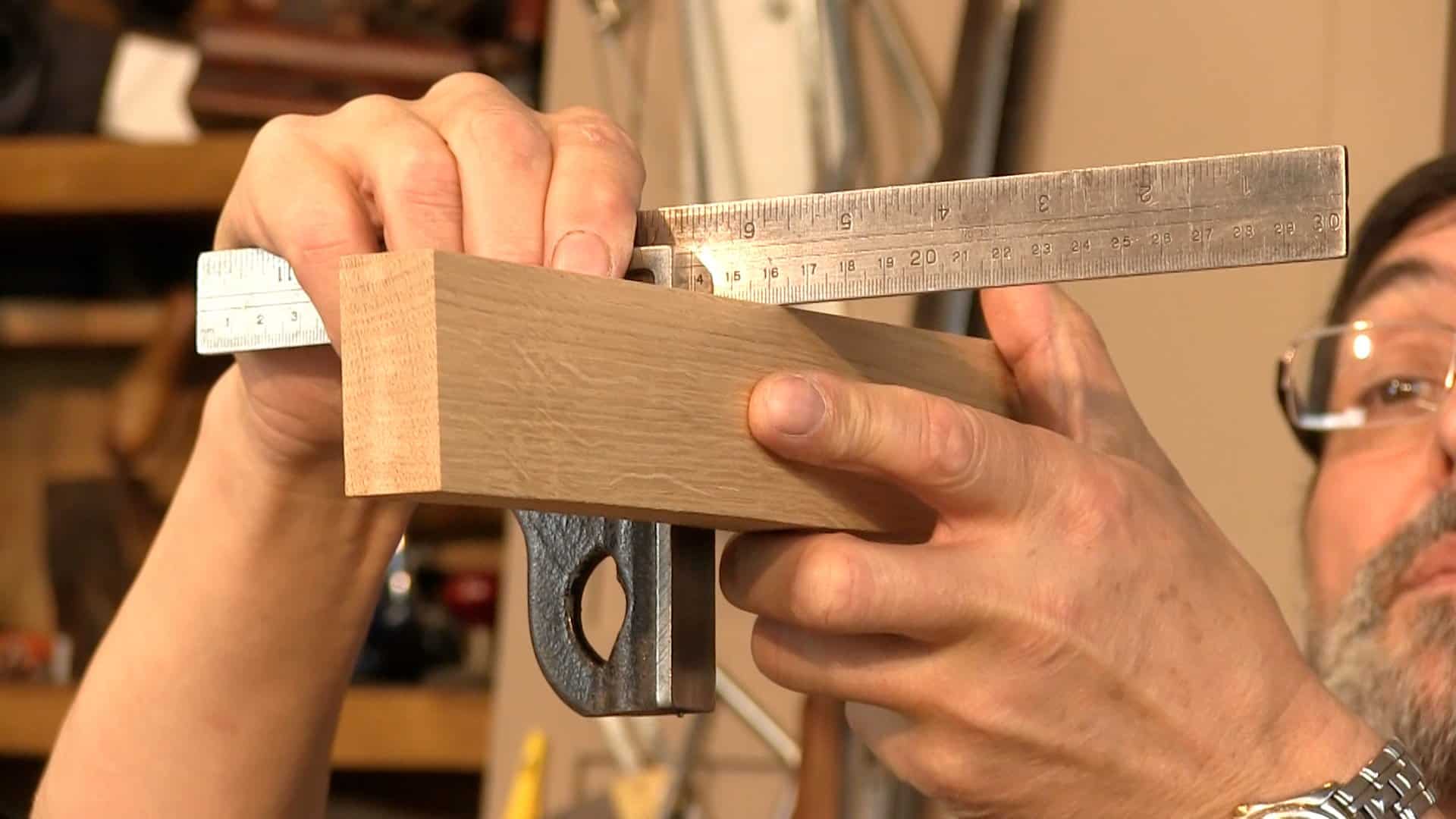

In this episode Paul shows how to cut the groove in the end pieces. He does this first with a plough plane and then, for the minimalist woodworkers, he shows an alternate method using only a saw, mortise gauge and a chisel.

Great job guys, thanks for this one. 😉

Awesome and thanks 🙂

great tips its not only being shown how to do a task but also knowing what to do if it doesnt go as expected :]

Oh i am so liking these video’s / projects I am learning so much, Thanks Paul and Joseph.

Steve

It is interesting to see what happens when things don’t go as planned. It’s wonderful.

Thanks for another good episode.

Paul should really flatten his bench if it is proving to be a hindrance. 😉

Scott- hang in there, a newfangled bench is in the works, with crossgrained wood to boot. With the output of videos and the level of craftsmanship evident in the work, Paul is showing how to go forth in less than perfect conditions.

Great! It is fascinating to see how you can achieve the same result with different techniques. Is always a pleasure watch your videos Paul.

Ghaaah – what a cliff hanger.

If you really want to impress me try getting the same results with a pile of rocks and a stick!

brilliant as ever Paul!

Getting it right is great BUT over the years I have learnt more and faster by having problems with wood, metal and software.

Paul I thank you for including the footage.

I smile when I see the work of the chisel verses the saw when removing large lumps of wood. Back in 1979 my apprenticeship had me removing steel in the same way with chisels. I should have a look to see if I still have my books EITB (Engineering Industry Training Board) We had to learn the “way of the chisels” before moving onto Shapers and milling machines.

I did find this YT that you may find interesting

Blacksmithing for Beginners – Understanding Cold Chisels I started it from 7min rewind to see it all.

https://youtu.be/e7umWmyjkGI?t=408

In the mid 1980 at my fathers Blacksmiths shop we converted to Plasma cutting for jobs like this.

The good thing about steel is you can weld a bit back on 😉 with no glue line.

Many thanks Paul for you training me in the art of wood.

John

I think the mistakes and odd grain left in helps a lot. Thanks for leaving it in.

I realize that you are reproducing a piece but I wonder if it would be more stable if the tenons were placed more in the middle of each board ie 2″ from the middle edge rather than 1″

You dont want it to expand to the center when it moves. So the offset tenon lets the movement happen on the outer edge keeping the center joint tighter. I dont believe he glued the centerline. If i remember correctly.