Dovetail Caddy Episode 4

Posted 22 June 2013

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

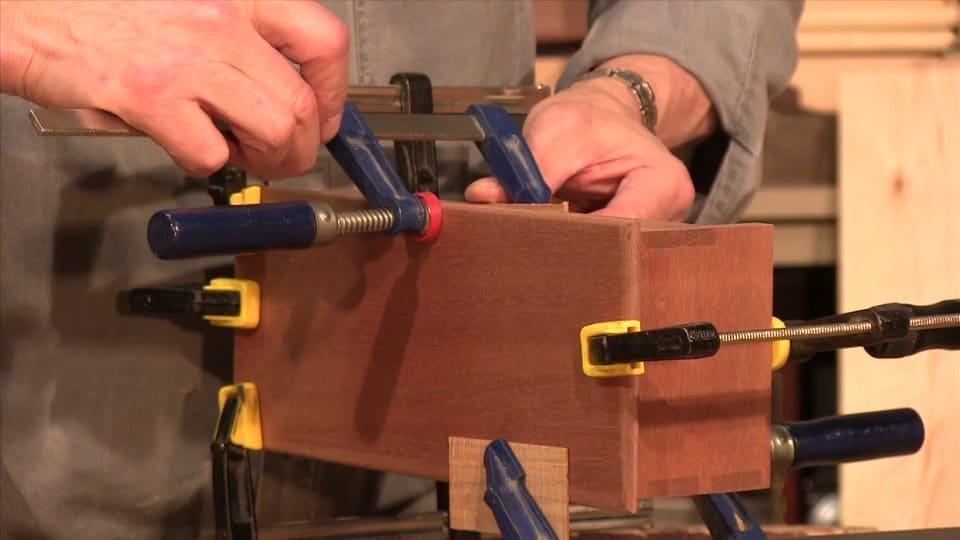

In this episode Paul glues the dovetailed corners of the box and then, using a plane, he rounds over the edges of the bottom. He then glues on this bottom piece.

Nice work guys, many thanks for this one.

So nice to watch the creative work of the film crew and edits.

received #4 today but don’t have #1,2 or 3…???

Hi Norman, parts 1 2 and 3 should be available to anyone, either free or paid members. They are in the menu under ‘Dovetail Caddy’. Please contact us if you still cannot access the other videos.

With this and your candle box I always wonder about expansion/contraction of the solid bottom. Why doesn’t this split or loosen the glue joints?

Paul, Totally enjoyable, learning & building skills, filling in the blanks, with each show thank you

Steven

I believe that the small size means that expansion and contraction are not significant enough to cause any problems. We will be looking at what to do on larger items in future projects.

Paul,

Very nice video! And, eagerly await learning about dovetailing techniques.

If the box is much larger, is planing the dovetails still feasible? I worry about my ability to plane wide surfaces at this critical juncture.

What about a scraper? Would that be an acceptable alternative?

Thanks,

Hi Praki,

Planing wider dovetails should be much easier. It is actually the small size of this box that makes it more difficult to plane.

Regarding scraping, I would prefer to plane rather than scrape if possible. Especially on end grain. However, it could be that scraping will be the best option for you.

Test plane and scrape on a scrap if possible.

I’ve mentioned that I’m taking an Intro to Woodworking class at the local community college. Because it’s a class, for the most part, I have to do things the way I’m told (authority issues, anyone?). One thing the instructors got after me for, was dragging my plane back across the wood after the shaving stroke. They say it quickly dulls the blade. I’m trying to figure out what Paul is doing. It sounds like he drags his plane back without compunction. He could, however, be slightly lifting the back end.

Which is it?

One of the other things I have to do their way, is sharpen my blades at a 25°, then put a micro-bevel on it. This is time-consuming, though less so once my plane was sharp in the first place. Nevertheless, I have to register the blade properly in the angle jig, make sure my waterstones are flat, etc. So at a minimum it takes at least 10 minutes to tune up the edge. I don’t think it takes Paul more than about 30 seconds. So, does he not really care if he’s dulling the edge by dragging the plane back, or does that not really dull the blade.

As a follow on to all this, I think there’s a lot of “conventional wisdom” in class, in the specialty magazines, and generally among woodworkers that’s never really been examined. I wonder if this isn’t one of those things.

Sorry for the length.

Randy

One other thing. That sapele looks like it’s SO nice to work with. Through some mis-communication, my lack of knowledge, and a holiday weekend when the local hardwood supplier was closed, I ended up with curly maple for my first project. What a disaster! The only good thing to come out of that is that I ought to be able to plane anything after this.

Actually, if Paul could do a demo on planing tough grain, that would be great!

Thanks,

Randy, it may be a bit late to contribute my 2 cents worth, but oftentimes curly maple must be dimensioned and planed as close as possible accepting some level of tear out. The basic tips can help a lot. Namely have your iron super sharp, reduce mouth opening, skew your plane, ensure your chip breaker is optimized, etc. If you have one, a bevel up plane with a steep (50 degree) bevel can help tame tear out (but often not eliminate) on tough woods, at least it has helped me. LN makes bevel down planes with additional high angle frogs that can be swapped out for tough grain and LV has a bevel up plane iron ground to the steeper angle. Of course you could always regrind your standard bevel up plane blade to a steeper angle for a project using tough wood, but switching back and forth more than a few times seems wasteful to habitually regring good steel. Once it’s been planed with some high angle solution (or just a VERY sharp no. 4 smoother if that’s all you have), tear out can be removed and it can be smoothed with scraper tools like scraper planes, no. 80 cabinet scraper, a LV scraper attachment for a standard bench planes and card scrapers. Keep in mind that Paul has said a number of times ‘no matter what some people tell you, there are some woods that can not be effectively planed.’ This is so true, but so rarely admitted by those interested in selling tools.

Excellent answer, but I am a beginner.