Sharpening the Frame Saw

Posted 14 November 2015

This is an episode in a free series. Want to watch it? It is free to do so, you just need to log into the site, and you can enjoy this video and many other videos we think you will love.

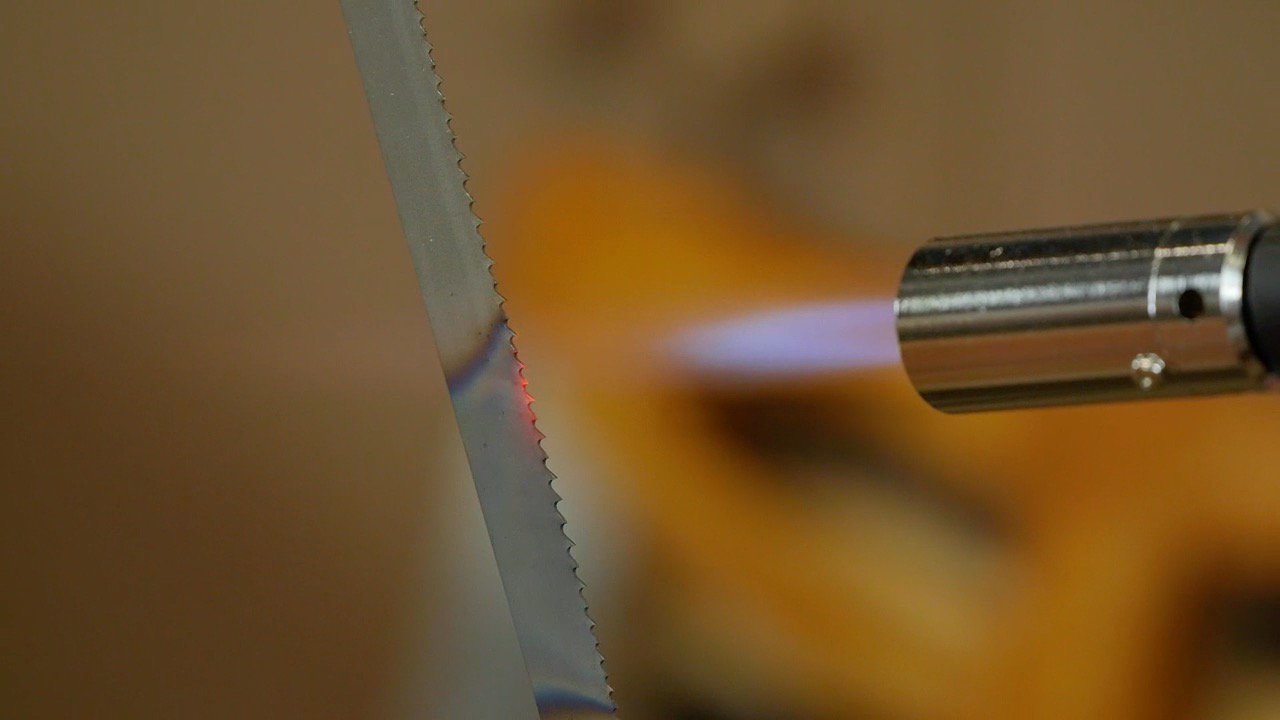

Paul discusses the different blade options that are available for joinery and metalwork. He then goes through what you might have to do to soften the teeth to enable sharpening with a saw file as well as cutting bandsaw blades to length.

Paul discusses some of the saw and blade options in this blog post.

That is so enormeosly useful !!! Thanks a lot again Paul!

Paul,

I love that old saw clamp you use! Any chance of a video on making one in the future? It would complement your sharpening videos well!

Chris

I was thinking the exact same thing.

Aloha Paul,

I too was thinking that exact idea. I feel that would make a great project for all of us to follow along and make one.

Mahalo, Floyd

Ditto!

Chris, I built one like Paul has and it works great. It required the use of two mortise and tenon and I actually learned to make that joint constructing the saw clamp. Of course I learned how to make the M&T watching Paul’s videos. I have sharpened over 30 refurbished Disston saws using the clamp and nothing slips when you tighten the jaws . Paul is an excellent teacher and most generous man.

I made one loosely based on the one Paul is using. Here is a link to the blog post with the drawings:

https://paulsellers.com/2012/06/solid-saw-chocks-simply-made/

Thank You, Mr Sellers and all the WWMC team!

Thank you for the lesson.

Kinda wondered if one could use the same trick with one of the unsharpenable wood saws that one often sees discarded in skips etc: heating to create a file-able saw. Perhaps one still wouldn’t like the plastic handle but in a pinch, if this works, it could be useful. I have collected several antique saws which are just wonderful & sharpen well even for a novice like me, but would still be interesting to try one of the disposable blades to see if it can be made resharpenable by heating.

Regards,

I was wondering the exact same thing Arthur and plastic handles can always be replaced.

Every time I go to the hardware store I wonder the same thing. 🙂 But I was thinking of just cutting the hardened teeth (plus 1/4-1/8 inch) off with an angle grinder. If someone tries it please share.

From what I read until know, often only the teeth are hardened, not the complete blade. So it should be possible to flip the blade around and cut new, resharpable teeth on the other side. I want to try that some day with bowsaw-blades from finetools.

Arthur, I just tried it with the Husky 15″ hand saw with scabbard” from Home Depot. I ran into a couple of problems. The original saw has Japanese style teeth so they have to be removed prior to sharpening. The handle is not removable so if you could soften the steel you will soon run out of room where the blade meets the handle.

Using a torch, starting at the toe I heated the toothed edge of the blade to bright orange then moved up the blade as necessary. This seemed to be working but about half way up the blade it became obvious I was warping the blade and by the time I reached the handle area I could no longer heat the tooth edge because the handle was in the way and starting to melt.

This operation resulted in a blade that was loose in the handle and extremely warped, snake like and unusable. I tried to straighten the blade but gave up after several tries. My efforts to straighten the blade actually made it worse as the blade is now snake like and twisted out of flat by 5/8″ along it’s length.

Unfazed by my clear failure I chucked the saw into my vise and using a 12″ mill bastard file I took most of the teeth out of about the first 5″ of the saw at the toe end. I then proceeded to sharpen the saw in a rip pattern. I only bothered to resharpened the first inch as I didn’t want to waste a good file on a hopeless project but the softened saw plate took to filing well and I was able to form excellent saw teeth in the steel.

Lessons learned? First, if the saw doesn’t have a removeable handle don’t bother. If you find one with a removable handle you will still have to deal with the saw plate warping. Don’t buy Husky brand saws they are not sharp. I bought mine for the scabbard which I really like. I am a self employed carpenter and regularly use Stanley hand saws on the job site as they are sharp and last through a project or two.

By heating and taking the temper out to sharpen ,don’t you need put the temper backin for the teeth last longer when finished?

Roger Bredeweg

You certainly could. Just reheat after sharpening and quench in oil or water while still hot. Perhaps use one hand to heat the blade and a second hand to follow with a spritz from a water bottle. Follow that with a soak in the oven at 350 degrees for about 45 minutes like Paul mentioned to temper the blade. This will take some practice to get the temperatures and timing right but it is doable.

Very helpful. Thank you very much.

Used this technique on 6 cheapie silverline 600mm 14tpi ‘compound mitre saw blades’ I got for EUR20 incl shipping off ebay. Worked a treat 🙂

I just put the teeth under the gas hob until the hardened part went beyond blue. Took maybe 5mins a blade. Then I sharpened for a rip cut using one of Paul’s other videos and the quality of the cut in the frame saw I made is amazing for such cheap blades.

Thanks, Doug

Would this work on other hardpoint saws? Panel or back saws. I assume that it will.

Also i keep seeing cheap old butchers saws – as the frame is deeper than a hacksaw i was considering getting one to experiment with.

350 degrees?

Paul talks about heating the teeth to Cherry red, also using a blow torch. He’s also British…. So I take it he means 350 Celcius…

…but who has an oven that gets to 350 Celcius? Does he mean an industrial type oven?

Confused…

I’m pretty sure he’s talking about Fahrenheit, not Celcius. 350F sounds about right.

could the heating trick also be used to sharpen hardened handsaw blades ,would be good to get some practice sharpening and tooth setting with old cheap saws

Will the annealing technique work with bi-metal metal cutting band saw blades, which are the great majority of the blades I’m seeing for sale online? I guess for 12 dollars I can find out as the cost I’m seeing on Amazon.

Will

Will.

Paul has a video on annealing and sharpening portable metal cutting bandsaw blades here:

https://woodworkingmasterclasses.com/videos/making-frame-saw/sharpening/

Will the annealing technique work with bi-metal metal cutting band saw blades, which are the great majority of the blades I’m seeing for sale online? I guess for 12 dollars I can find out as the cost I’m seeing on Amazon.

Will

If I heat the teeth with a blow torch, let the teeth cool, and then sharpen them; do I need to still put the blade in the oven for 45 minutes @ 350 to temper the teeth. Does temper mean to harden the teeth?

Hello all,

I don’t think we can give definitive answers on any of these I’m afraid, without trying ourselves. You can certainly try on an old bandsaw blade or hardened tooth saw.

Best, Phil

Any suggestions on finish to use on the frame? Boiled linseed oil, or shellac? I used some maple that had a little bit of bird’s eye to it. I really appreciate the videos , as well as the comments.

Hello Ryan, shellac or blo (boiled linseed oil) both work well. Just be careful how you dispose of anything to do with blo.

Can I use this method on Japanese saws? If yes, any idea how to sharpen them later?

Hasan,

Google– 35 srconds

https://www.woodmagazine.com/tool-reviews/hand-saws/how-do-i-sharpen-a-japanese-pull-saw

Craig

Hi Hasan,

I passed on your message to Paul and below is his answer:

Usually not, unless the teeth are non impulse hardened, but the likelihood is that most Japanese saws will have hardened teeth. In our modern age we have introduced a pattern of using hard-point saws which makes them impossible to sharpen.

Kind Regards,

Izzy

@Alec I’m not sure what size your frame saw is, but I’ve heard good things about Blackburn Tools (Blackburntools.com).

They supply a 1.25″x16″x0.025″ and 1.25″x24″x0.028″ blade for frame saws. They are 8 and 6 TPI respectively.

Highland woodworking has frame saw blades in 400mm and 700mm lengths in several types, including rip , crosscut, and also impulse hardened Japanese style teeth. Prices vary from $10 to $60 or so.

https://www.highlandwoodworking.com/search.aspx?find=Frame+saw+blades

I had trouble drilling the hole to re-purpose the bandsaw blade. My drill bits must be wrong.

thanks,

Danny

Set the end on a stove if it’s too hard. That will soften it up. Just get the end kinda red.