Sellers Home Side Cupboard: Episode 9

Posted 14 December 2022

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

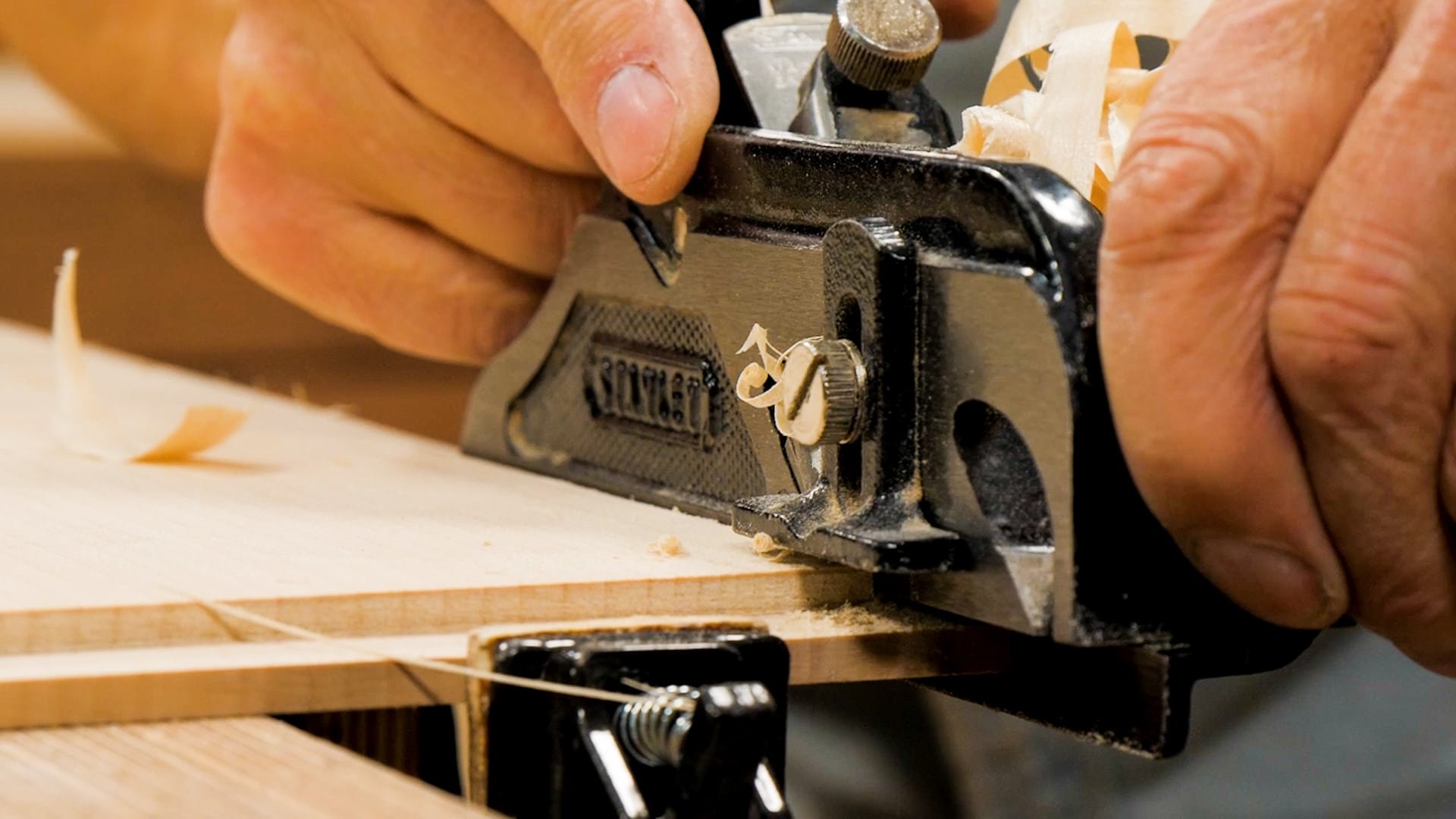

The episodes are bringing the whole cabinet together piece by piece, and in this one, we create the panels for the doors, fit them and then glue up the doors ready for fitting. We also move ahead with creating the divider rail to separate the drawer from the doors, which are dovetailed into the sides of the cabinet and facilitate fitting the drawer rails and fitting the drawer to the cabinet. The drawer front is what we call an overlaid drawer front; this also serves as the stop for the drawer. Once completed, it lines up with the doors immediately below the drawer – Lots of planing and fitting techniques to learn from throughout this episode.

Very nice to see a second completed Side Cupboard at the end of the workbench. A fortunate recipient or a matched pair for the Seller’s Home?

They are a matching pair for Sellers Home.

Really enjoy all the additional comments about the techniques Paul uses to get the precision that he wants for his projects.

Hi,

Regarding the two strips of wood beneath the drawer, the drawer carriers, Paul mentioned that the back screw has a washer on it to allow expansion and contraction of the side piece of the cupboard (starting at 25m20s).

Why isn’t the same method used with both the front screws?

How can the side piece expand and contract if the front screws don’t give any room for it to occur, only the back screw does?

Thank you

Antonio, it is all to do with the distances between the screws. The movement between the two screws at the front will be minimal as the distance between them is so short. Wood primarily expands and contracts across the grain, the wider the panel the more movement you will get.

Imagine clipping a rubber band at the edge of something rigid, like a sheet of glass. You can tug on the rubber band and stretch it along the rigid glass. The glass stays still and the band stretches along it. Same thing for what Paul has done with the runner. What matters is relative movement. The drawer runner is rigid because it is long grain and the cabinet side is like the rubber band because we are going across the grain. You can choose to pin down the rigid piece where ever you like and the side of the cabinet will expand and contract on either side of where you pinned it down. As Paul Rowell said, keep the pinned down distance small, a few inches.

How you pin down can matter. Suppose Paul butted that runner dead tight up against the front drawer support (the one that goes across the opening and is dovetailed into the sides). Suppose he did that and then pinned the runner in the middle. Now, if the cabinet contracts, the runner would push against the dovetail and could push the front support out of the cabinet. I’ve seen this happen. But, if Paul pins that very same runner at the front, then expansion and contraction will lead to relative movement at the back of the runner and it will be impossible to push out the front support…as long as the runner is cut short of the back of the cabinet….leave a gap back there! Or, you could pin in the middle and leave a gap behind the front support, but what Paul did looks tidier.

Another form of this is to glue mouldings for a few inches near where they miter at a corner, but nowhere else. Small nails / brads are used elsewhere. Now, things are pinned at the miter, so it doesn’t open and close, but there may be movement at the back.

I’m building a clock right now. I have to think carefully about this for the bonnet sides. I have to pin them at the front so that the door opening doesn’t change with humidity and will let all the movement happen at the back.

Sorry this was long….hope it helps.

Now I understand! Thank you both for your clarifications.