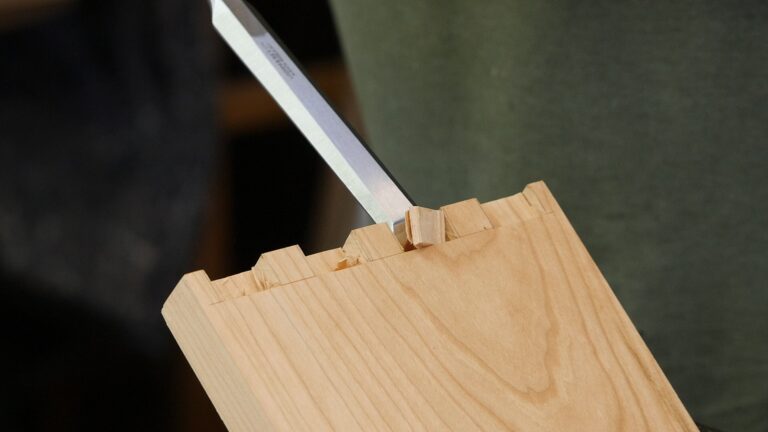

Keepsake Box: Episode 5

With the box construction complete, it’s ready to be finessed. Paul refines the shape of the feet, and scrapes and sands the surfaces in preparation for applying a finish. Shellac is then applied with a brush for an even, durable finish. The last few finishing touches are to fit a stay, in this case using epoxy, and fit a leather lining in the bottom of the box.