Coasters – Episode 1

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

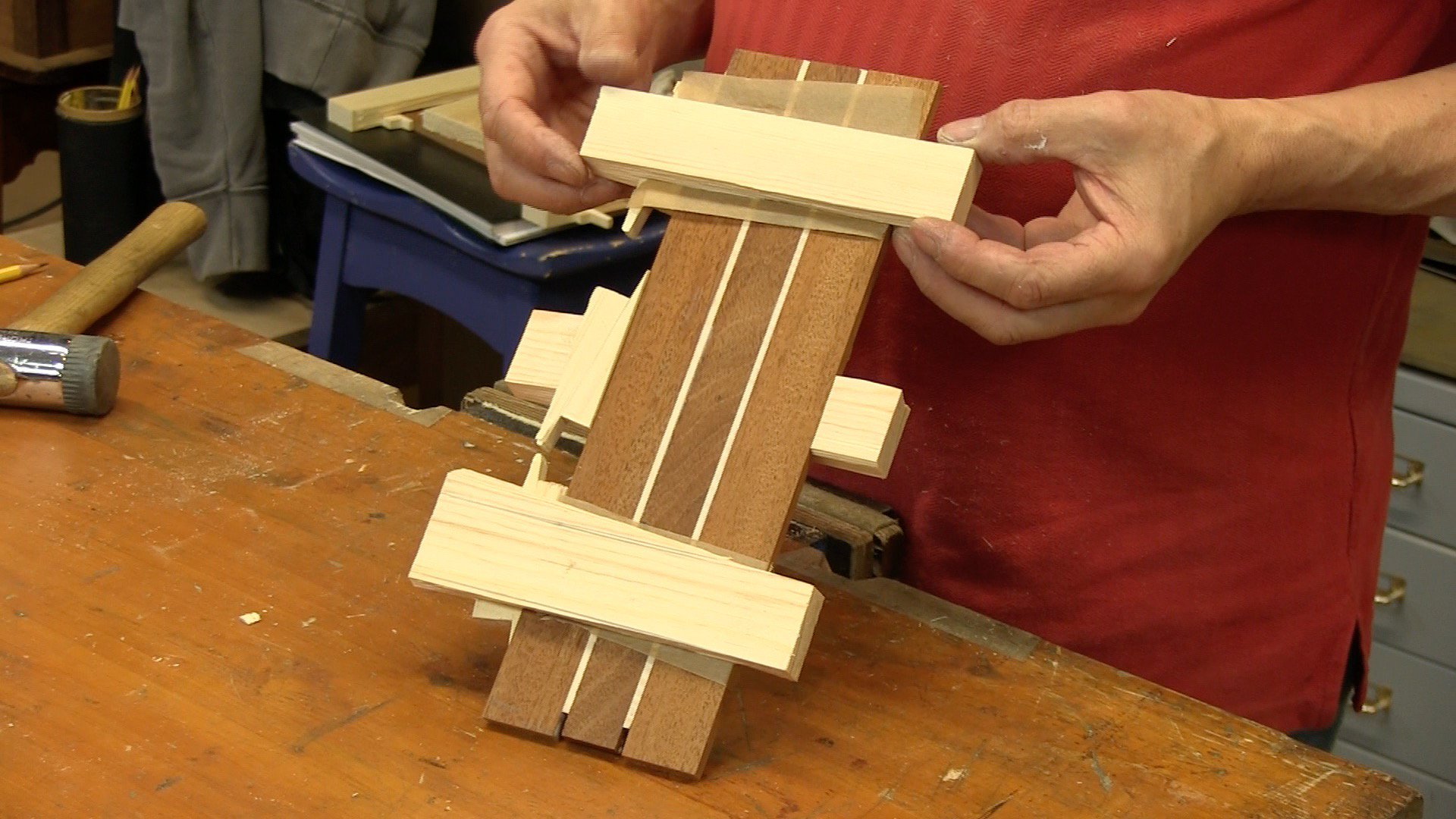

The first stage of this project includes a number of useful techniques for accurately dimensioning thin stock, including the thicknessing jig. Paul then introduces a new clamping system used when laminating thin stock. Once this is glued, he scrapes the laminated piece in preparation for cutting the coasters to size.

The 720p file is only 697Mb for those who are bandwidth phobes

Thanks for pointing that out! I have corrected the size displayed.

thanks for this Paul, her who must be obeyed was watching this over my shoulder and wants two sets (with place mats to match) no pressure then lol

Paul thank you for this, what a fun project and am looking forward to making a few sets. I also love the simplicity of your jigs and holding methods.

Steve

Bring back the Masterclasses

Is that a chromed Stanley 0-10-598 I see or have you somehow manage to wear the finish down to a polished surface?

I’ve just been looking for some offcuts to have a go at making these….can’t believe how much people are charging for them….especially ebay…..is there anywhere I can get offcuts for a reasonable price?

I would look to a local cabinet maker or other business tat uses wood in their manufacturing. As long as you are clear to convey the sense that you will not be competition for them they may let you rummage their off cuts bin. Just be sure to leave it neater than you found it.

Where in the world are you?

I’m in Cornwall In England……I think people are wise to others using offcuts for turning etc and are now charging silly money for what they would otherwise be throwing away.

“pretty benches” haha! I must confess to being a little jealous at times of all those beautiful Andre Roubo style benches floating around the internet. Thank you for keeping me humble and realizing what I have works perfectly.

Here Here !!! simple solutions to the everyday wood working task Love it .

Great idea to remember about making wedges quick and simple.

Thanks so much

I’m a woodworking newbie, so forgive my ignorance, but how do you go about getting the rails on the thickness planing jig exactly to thickness? Would you flatten one face and then run a gauge line 5/16″ and plane to the line?

Also, is it cheating to buy my lumber S4S to help me along? 🙂

Troy, you would plane the rails together to make sure they are the same thickness. Make sure they are flush at the bottom when clamping in the vice. Buying s4s is not cheating 😉

I’ve been trying to make these and having great trouble with the lamination…I can’t for the life of me get these to glue up without twisting or cupping…too much pressure I thought…so tried with less and they didn’t stick well….I wonder if my pieces are too thin…I went for 6mm as my thickness…maybe I’ve just gone too thin

hi Barry i’m not surprised they twist if you’re only using 6mm ,as Paul uses 16mm i think 6mm would twist with the heat of a coffee cup, i’d try the 16mm 5/8″ first at least you’ll get thehang of clamping up.

It doesn’t look like his stock is 5/8″….surely that would be massively thick for a coaster?

I can only assume you’ve confused thickness with width….my pieces are 20mm wide by 200mm long by 6mm thick

It doesn’t look like his stock is 16mm…..that would be massively thick for a coaster surely?

have you viewed the drawings sheet that comes with this project

Well I finally got around to finishing a set of these….only made 4 because I only had enough scrap wood (Mahogany and pine for the stripes) lying about to make 4 identical ones….I used the wrong varnish really…just used what I had lying around which happened to be yacht varnish rather than buy a £6 can of varnish just for 4 coasters that I was only really making as a bit of practice anyway….they didn’t turn out too badly…little unhappy with the finish but I can always rub them down and try again. Shame I can’t seem to add a picture to show you….the advice I received really helped…I went to a thickness of just about 8mm and it worked great….I did change the clamping system though….instead of cutting a recess into a board I simply screwed two rails of 1″x 1/2″ strip wood onto pieces of 4″X1″ board….it just saved the time of cutting the giant recess but worked just as well. I’m certainly going t make more of these in the future….hopefully in oak next time with maple or ebony(or both) for the stripes….I’ll also switch to a much faster drying satin finish varnish as recommended in the video over the nasty yacht varnish I used this time. This is a great project…good fun and can actually be quite testing especially when jointing and gluing up….well worth the effort though.

my mistake sorry they are 5/16 not 5/8

Barry, his laminations are from 5/16″ thick stock. I’ve just done mine today from 5/16″ material and they are coming out pretty flat and straight. Remember that you’ll be cutting them to about 3 7/8″ long (or whatever your final design calls for) from the 12 or 13″ long lamination, so the twist in that length will only be a fraction of what you see in the glued up lamination.

Also, Paul mentions (very quickly, so it’s easily missed) that he dimensions and squares his stock very precisely, so that when he glues up the laminations there will be less problems. I think he does this while the pieces are still about 3/4″ thick, so it’s easier to dimension and square them, then he cuts length wise along the edge to create the two (oversize in thickness) pieces that will then be planed to 5/16″ thick .

Good luck

So mine at 6mm could be just a tad too thin then…maybe I’ll try 5/16″ instead…..thank you to everyone for your help…I really appreciate it guys.

Thank You WWMC Team!

Hey all,

I’ve successfully glued up some coaster material and am in the process of cutting them to size and planing them square on my shooting board (thanks Paul, I did that earlier this year.

However I’m a bit stumped about the size for the holder. I’ve been able to decipher the sizes for just about everything else from Paul’s verbal instructions, but not the size for the holder. Someone here mentioned a plan sheet? I have looked around here and can’t find a link to one. Can anyone help?

Hello @randy-c,

The drawings temporarily disappeared but can now be found on the project information page. Hope that gets you what you need.

Best, Phil

Many thanks. Just what I needed.