Console Table: Episode 1

Posted 26 June 2019

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

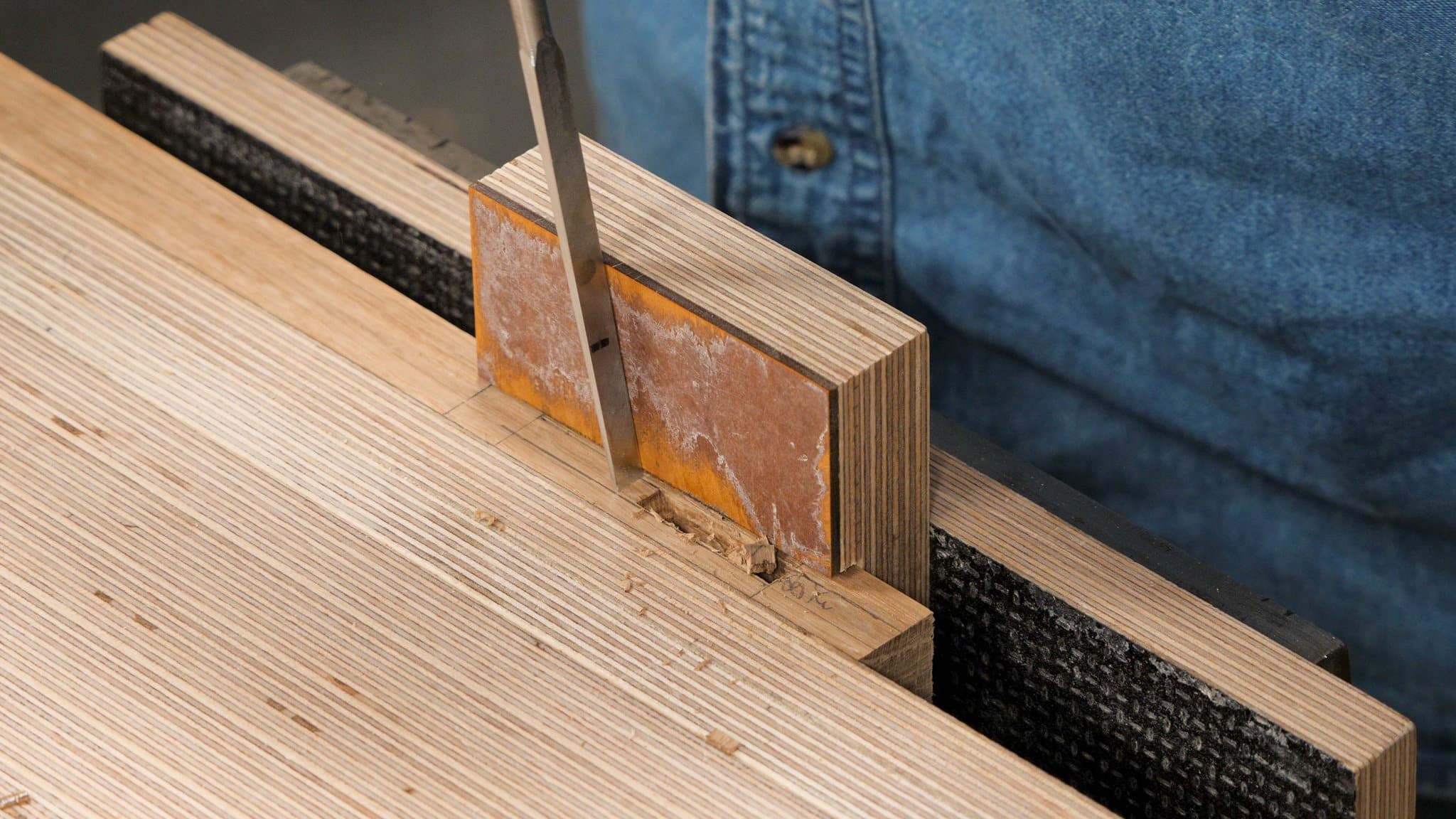

Paul presents here a highly unusual flat-stock constructed table. In this opening episode, he runs through his wood choice and shows how to prepare the wood for joinery. He then lays out and cuts a mortise using a mortise guide. We hope you will enjoy this great little console table!

Nice trick on the haunch. 😉

Nice quick mortise cutting as usual… much faster than I manage!

2 questions though…

Why the offset for the mortise?

Why is the haunch not “hidden”, like the sloped one… or to put it more generically, when should you use a sloped haunch, and when a full one?

Thanks,

Matt

Hi Matt,

Paul says:

Offsetting the mortise instead of centering it in the leg, means that the tenon length will be maximised and therefore give good strength.

Answer 2: just to give my audience the options when they progress their woodworking so they can choose which ones they want for themselves. The sloped haunch is the fastest but some of us are not looking for speed.

We also call a dinning table a table and so too a bedside table. It’s just a matter of a name.

Kind Regards,

Izzy

Thanks… But we “dine” on a dining table, and bedside table is by a bed… What is a “console” or consoling? I really don’t know!

Thanks,

Matt.

If I’m feeding a troll, please excuse.

The word console has several meanings, including “an ornamented bracket supporting a table top” — probably the term was originally used only for accent tables with corbels etc., but it seems the meaning has evolved over time. See also the similar discussion here: https://woodworkingmasterclasses.com/videos/console-table/#comment-110797

Btw, the price and looks of this non-wood console table may literally “console” some: https://www.1stdibs.com/furniture/tables/console-tables/melting-brass-console-table-hallway-table-zhipeng-tan/id-f_8615453/

I’m going to have to think about the maximum length thing… Still not making sense to me at the moment!

Hi,

Thanks for a really nice project! Can’t wait to get started on this. However, I just can’t get my head around the offsetting of the mortise. Now I understand the purpose for offsetting (maximize tenon length), but if that’s the reason here, aren’t you offsetting it in the “wrong” direction? Would you not want the tenon closer to the outside face of the leg, rather than the other way around? (which is the case here)

Best regards,

Jim

HI Izzy,

Would you try to explain the off setting of the mortise one more time, I just don’t see the reason. In fact, it would seem to me that you are weakening the inside wall of the mortise, while the outside does gain thickness and strength then. Is it also just for another version of how to make a mortise, or ??? Second question, why isn’t there a haunch at both ends if it is meant to prevent twist?

Hi @SIMSY @5IVESTRING @JPETERSSON

Paul says: My previous answer was because I thought it was for another table type where the leg was square, not this one, sorry. This was purely because I had an existing 5/16th guide.

Kind Regards,

Izzy

Ahhh, That makes sense now!

Thanks.

Matt

Oh, and one other question…

What make a table a “console” table? Why isn’t it just a table?

Matt

How do I figure how much of what sized wood to buy?

It looks like maybe a 6ft 1×8 board? If so, how many do I need to bring home from the store?

Joe, you can lay out the cut list on paper and figure out how many boards to buy. Just leave extra for saw cuts and planeing.

Hi,

Paul says:

Generally I add up the square footage of a piece and then add 25% more for wastage.

Kind Regards,

Izzy

BRAVO ! Love the running commentary and “thinking out loud” as you go. Your gift of communicating your experience and knowledge is truly priceless. Thank you.

Since Matt opened Pandora’s box already ” why use a haunch at all” ?I have read some texts that mention the haunch preventing twisting or the sloped haunch being to allow expansion across the rail. None of these ring true but I don’t have the experience. Is it just possible the that one day someone blew the end of a mortise out levering against the end and that started the haunch? I understand the benefit in a rail and style door to allow you to cut the groove all the way.

Paul makes the chopping look so easy and quick without rushing. It took me about 18-20 minutes for each mortise. I’m using cherry so not sure if it is more difficult than oak. My 1/4″ chisel always seem to get stuck as I progress deeper and deeper toward the end. I have to ease up on the depth for first pass. I can’t lever out like he does as the chisel get so stuck I think I will break it. Not sure how he is able to chisel so deep and able to lever and get the chisel back out. I am not taking big bites, only 1/16″ and never more than 1/8″ and my chisel is freshly sharpened too. Just get stuck at bottom where it is tough to get back out let alone lever. Any ideas?

Thanks.

@BEACH512 my guess is that you need to study how he starts more carefully. Suppose you are progressing in the direction going away from you. Then, the bevel should be away from you. When you drive the chisel with the mallet, it will try (and succeed!) to move towards you. So, there must be clearance for it to move into. Otherwise, it is like driving a nail and the chisel will just get stuck. This means that opening up a gap at the start is important. You’ll see that Paul goes back and forth a few times at the start in the first 1/8 to 1/4 inch of the mortise to free up the first bit. It’s a little fussy, but must be done. Once you have a little bit removed in that first 1/8″, you can point the bevel away for good, and take your first bite of 1/16 that you describe. The chisel will go a little deeper and drive the chip into the opening you made. I suggest you look on Youtube for Paul’s video of making a mortise in a piece of wood when he’s put a piece of glass or plex in place so that you can see how the mortise develops. He made this years ago. Seeing how the chisel moves, how the floor of the mortise slopes, etc., will probably help you a lot. All my words here likely won’t. 🙂

Ed – Yes, you are right on about leaving enough of a space at the start and your analogy of the nail is a good one. Thanks for the feedback. I have watched the mortise he cuts with the glass view but I need to study it again. I will keep practicing with this in mind and try in oak too. Many thanks!

@beach512,

In addition to Ed’s erudite comment: with all apologies, and absolutely no intention of being patronising, please note that in Mr P. Sellers’ video on chopping mortices behind [plexi(?)] glass, he’s taking bites out of pine that “one cannot chew” from cherry.

Furthermore, as a member of The International Support Group of The Economy of Warren, ME; I’d like to point out that a ¼” mortice chisel has a very low likelihood of breaking while used to clear the waste. In addition, those chisels aren’t at all as wide as the “reference pig-sticker” that serves as comparison in the video.

Hi,

I passed your question on to Paul and his answer is below:

You should remember that I have cut around 120,000 of these joints by hand and the nuances I use have been garnered over many years. It would be impossible to write down the feelings I get when I’m using a chisel that counters obstruction and argument. If you keep persevering without over expectation that with one joint it’s all going to come together, you will eventually discover your own success. Currently your success is just trying it, keep it up. We build from one success to the next!

Kind Regards,

Izzy

I completely agree with Ed,

That video is fundamental in understanding how (with this technique) the chisel is working without being over-stressed (or nailed).

https://www.youtube.com/watch?v=q_NXq7_TILA

Everybody should study it.

Note that Paul uses, from time to time, a narrower chisel to remove loose fragments from the mortise.

Do you have any preference in 25deg chisel vs 30 deg chisel when cutting mortices? I have tried chisels with 30deg chisels with thick edges and they move the wood out cleaner but seems to take twice the work. The thin edge 25 deg chisels go in easy but tend to twist easy and shreds one side of the mortise.

I have learned more about watching you than any other lessons I have seen in the last 15 years…. Thanks too much.

Hi Henry,

Paul says:

Grinding at 25 degrees as an initial step, simply gets the bulk of the steel out of the way. Chopping with chisels definitely requires that you have a 30 degree bevel rather than a 25 degree bevel which we mostly use for paring cuts.

Kind Regards,

Izzy

I assumed Paul chose the 5/16″ offset for the m&t joints to leave a slight reveal as is common in a great many tables.

Great series, instruction, craftsmanship & awesome job by the WWMC team putting it all together.