Wallclock Episode 3

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

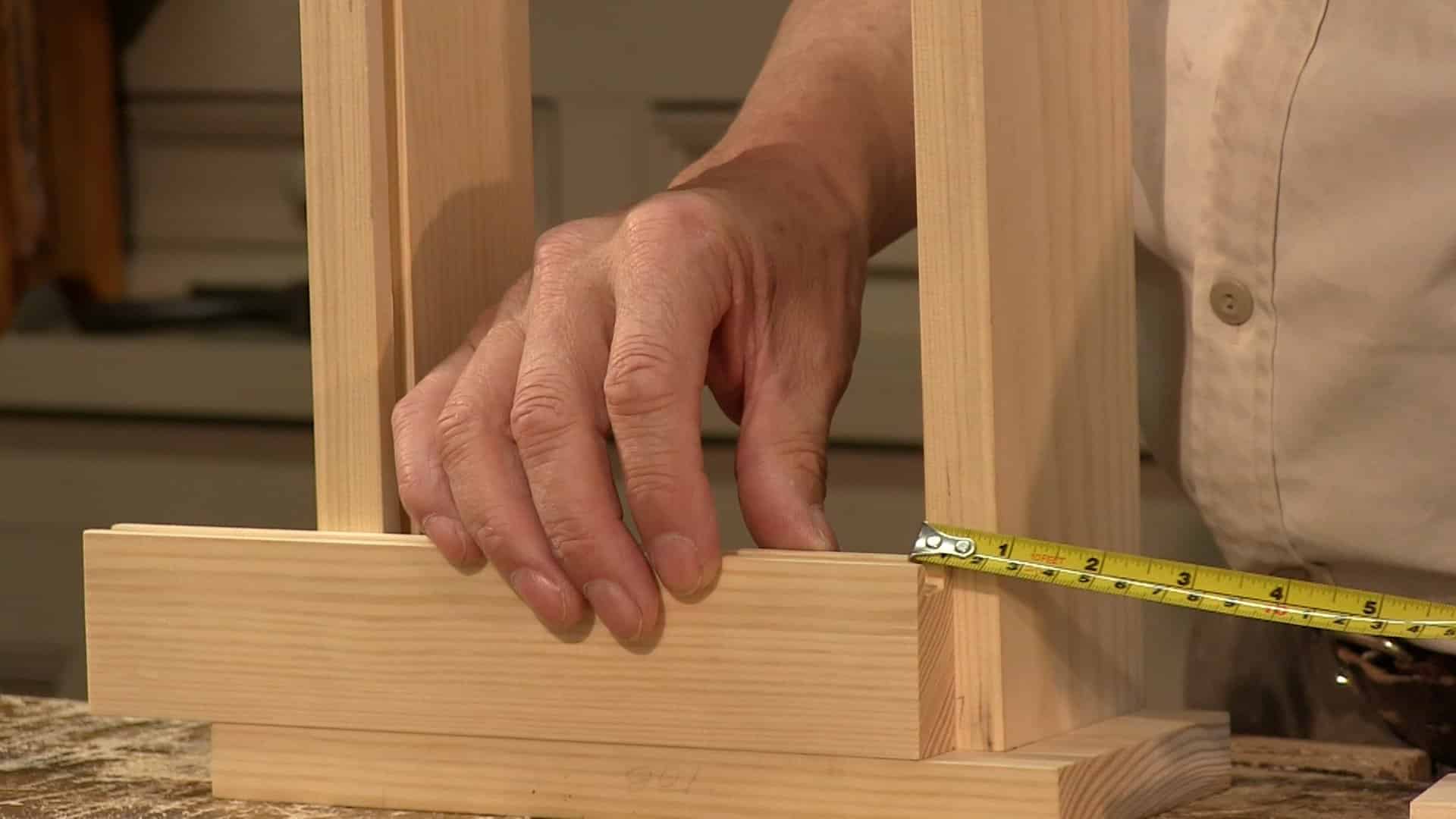

In Episode 3, you will learn how to cut a haunch on the clock sides to fit into the housing dado joint. You will learn about the use of the plough plane and will run the grooves in the sides. You will also make and run grooves in the rails.

Thanks Paul, another great episode. Nice job buddy 🙂

Thanks for making these videos “downloadable”!

Great idea and job well done, Paul.

The widest cutter I have for my Record 043 is 3/16″. Anybody tried using a bench chisel in one of these?

I have used old firmer chisels and some bevel edged chisels will work. They are also readily made from a piece of 1/8″ 01 steel flat stock.

Thank you for the varied techniques again Paul.

Even though I miss seeing your Marples Blue Chip chisels you’ve shown that the inexpensive chisels work well for the various techniques, paring, defining the knife line, chopping, etc…

For such short tenon cheeks, would we need to be conserned about switching between a tenon saw for the rip cut and a dovetail saw (US) for the crosscuts, if we choose the saw method?

No, a dovetail saw will do both.

Quick question, could you fit a back to the clock case, or dose it need to be left open.

Many thanks

No it can be closed in. Perhaps pin a 1/2″ x 1/2″ strip of pine around the inside as a false rebate and then screw the back to it.

When I presented my wife with her new wall clock, she decided it would live on the mantelpiece in place of the tatty old Ikea one we used to have. We generally used this area as a sort of ‘in’ tray for all our correspondence (mostly bills) so the open area behind the new clock is doing double duty as a secret compartment.

Got my plow plane in. I had never used one before, or seen one for that matter, before this and I should have practiced with it first, but I was too anxious to get started. Thought I had it all set and all the adjustments locked in, but while I had the fence locked tightly onto the rods, I didn’t lock the rods into the plane. The result was my first groove was angled. Lesson learned!

Vince,

Let us know if you need any advice. There is probably a way of fixing it if you haven’t already.

Hmm.. I bet it would not be that hard to make a Poor Man’s Plough Plane, similar to the Poor Man’s Router.

I am just about to release one on my blog. Will be finished with it soon and will make a video from it.

I’m a noob woodworker, but over the course of 60 some years of life, I’ve learned one thing. One can always identify a mater craftsman; he makes it look so easy. Clearly, Paul is a master.

One other thing, is the Stanley No.78 something one would use for this? Assuming, of course, that your groove was as wide as the blade.

The Stanley No.78 would not really work for this, as it is for cutting rebates (rabbets), and wouldn’t work to cut a groove. You can get hold of Record 043 or 044 at a good price on ebay. Check out the blog posts on plough planes by paul here: https://paulsellers.com/series/buying-good-tools-cheap/

I’m wondering if I’m missing something here. Is there any particular reason for cutting the groove before you cut the timber to length? I can see why you need the groove there to mark up the tenons but I don’t understand why you cut the groove first.

Hi Jon

I am also up to that stage of the clock build The top and bottom rails are that length as they are cut from same board as used for the top and bottom pieces, I also think it will be easier to cut the groove in a longer piece as it gives a better reference face for the plane fence.

David is right. It’s a longer reference face. The shorter the material, the more risk there is to misalign the fence to the workpiece.

Ahh, I see. Thanks. I had a lot of fun making the bulk of my clock this weekend. Learnt an awful lot about how not to setup a plough plane 😉

Wow, I just checked on the price of a Plow Plane… That is an expensive little booger. What other methods would you recommend for putting this groove in? I’ll don’t want to cheat but I might have to use my router for this until I can find one at a reasonable price.. I do have an old wooden Plow Plane but it has some missing hardware. That might be a project for the next rainy day…

You could do it with a hand router plane, but even a second hand Plough plane would be better.

I would not think using your router as cheating, nothing wrong in using both hand and power tools. If thats what you have to hand, use it buddy. 😉

You could do it with a handsaw and chisel as well. Cut each wall with the saw and chisel out the waste.

I think the majority of us are here because of the hand tool centric aspect of Paul’s teaching. However, we do compete nor judge. If a power router is what you have, use it. In the long run though I think that you will find a plow plane quicker and much more pleasant to use. Put it on your list and get it when you can.

Greg

Take a look at “Dovetail Boxes Episode 5”. Paul covers the saw and chisel method there.

Seems that there is an issue with this video number 3. It gets to 1.05 duration and finishes going straight to the end as though its only 1.05 long in total, so unable to watch. Help please!

Yes, I can see the problem too. How odd. I will get it sorted out.

@clembo, fixed! Sorry about that.

Same hear Clem, I checked it using Safari, Firefox and Chrome, and it stops at 1:05 every time.

Joseph will sort it out I’m sure

Thanks guys.

This video plays for 5 to 10 min and stops all the way through. I have played at least 10 others with no trouble at all. I am using an ipad or Mac PowerBook on the same server.

hi Peter i’ve just watched the video again to see if it stopped for me and it played all the way through no problem sorry i can’t be anymore help .

My woodwork has become so much more accurate and enjoy my projects so much more since using the knife wall methods that Paul uses so much

Things I learned while working through this project.

1) Keep your tools sharp.

2) Have patience and perseverance.

3) Do not trust big-box lumber to be flat. Make sure that the sides have no twist. None. Use winding sticks. I have a small twist on one side and, because of that, the clock will never sit flat against the wall. And, once the dados are chopped, it’s pointless to go back and fix the twist by planing. I think that the only way to fix it (other than starting all over) is to plane the back edge once everything is glued.

4) Remember, it’s not the destination; it’s the journey. Well, okay, it’s the destination, too.

5) It’s okay if the cats sleep/play on the bench while you’re working. Just keep the chisels covered.

If the cat sleeps on Your bench, everything is ok. Formerly my router and circularsaw disturbed them. Now they are companions in my shop. Another good point of woodworking by hand.

Things I learnt while watching the first three EXCELLENT episodes and remembering from school 50 years ago.

1) Sharp tools make the project so much easier and add to accuracy.

2) You are not allowed to finish a project quickly, short cuts are discouraged.

3) Good woodwork teachers are always surly and never smile [though I did see Peter lapse just a little in concentration].

Sorry Paul not ‘Peter’, got you mixed up with a comedian how dare I.

Paul,

As a southpaw, I note that plough planes on ebay all seem to be right-handed. Is there a remedy for that. How would you cut the groove if you didn’t use a plough plane? Thanks for your videos and excellent teachings. I am very grateful for what you and Joseph are doing.

Jeff

i dont have a plough plane or a router plane. what can i do with the stub tenons?

Paul I noticed you have Pimped up your Clamps can you provide some details please

: https://paulsellers.com/2011/11/4473/) have a look at this Paul

What # or size is the plough plane you use in this video? It doesn’t look like a #45.

James, I believe Paul’s plow that he uses in this project and others is a Record 043 or 44.

How would this groove be done not owning a plough plane? Can you demonstrate how?

The “groove” is basically a housing dado that isn’t stopped. Lots of demos of doing that on this website, including one on this Clock build. Grab a chunk of wood and experiment.

Grooves run with the grain, dadoes crosswise. They aren’t the same.

@sdbeggs In one of the projects, Paul shows how to cut a groove by marking out with a mortise (or other) gauge, and then sawing the walls with a tenon saw. You then clean out with a chisel, bevel down I’d guess. If you have a narrow router plane blade, you could use it to level the bottom. This is from memory, so don’t rely on it. I don’t recall which project it was, but he’s mentioned it a few times. You could clamp a batten on to guide the saw or you could find the video and see how Paul does it. Be aware that running a knife on a line or gauge line along the grain is almost certain to run off the line.

If you want to say a groove is like something, it’s like a mortise. If you got the near end to depth first for the first little bit, you might then work away from you, bevel away, chopping down to that established depth. If you had a batten to guide the chisel, it would be like a long, shallow mortise, and you could use the batten to pare the wall at the end. Be warned, that’s me just thinking aloud.

Point taken Ed. Your analogy to a mortise makes more sense. Of course I might also say that it’s still like a dado…………..just one that’s really really short and really really wide! LOL

The main point I was trying to make is to look around on this website for information and even more important grab some wood and experiment a little with the tools we have available.

Well Ed, the video is demonstrating cutting a groove, that I mentioned. I was not asking for a semantics class. I was asking for a video demonstration no using a plough plane. I will try again to find the video you reference you stated to not rely on your memory. Sure, bevel up or down I have done some tasks alternating based on grain and task at hand. Thanks for you input. I was specifically asking in the hope Paul would create a video for this exact issue. I have created dados shorter than my saw, but have had trouble with long dados or grooves.

Stanley,

Here’s a video I found, with a little looking, where Paul makes a groove without a plough plane: https://woodworkingmasterclasses.com/videos/dovetail-boxes-project-info/dovetail-boxes-episode-5/ So it looks like Paul HAS created a video for dealing with this exact issue. At least it’s one way of dealing with the issue. Maybe there’s others.

As far as your saw issue, someone a while back mentioned using one of these saws for long cuts: https://www.japanwoodworker.com/products/3-rip-crosscut-mortise-saw-azebiki-ryoba-nokogiri?via=58923197617070231a00002d%2C58923197617070231a000038 I like the looks of this saw…..might have to get one to add to my arsenal.

PS: How did you end up solving your dilemma of cutting sixteen 3/8″ mortises with a 1/4″ chisel?

Best of luck in your endeavors. I was trying to save you the pain of trying to cut a groove with techniques meant for housings. The direction of the fibers matters.

Stanley,

In the Hanging Wall Shelf video starting at about 15:00 minutes Paul lays out some mortises going with the grain that you might find to be a useful method for what you’re wanting to do. Might be a bit time consuming for the 3/8 by 3/8 grooves you need, but this method would certainly work.

Also the Dovetail Box Episode 3 has some good info. I sent this earlier, but it didn’t seem to get posted.