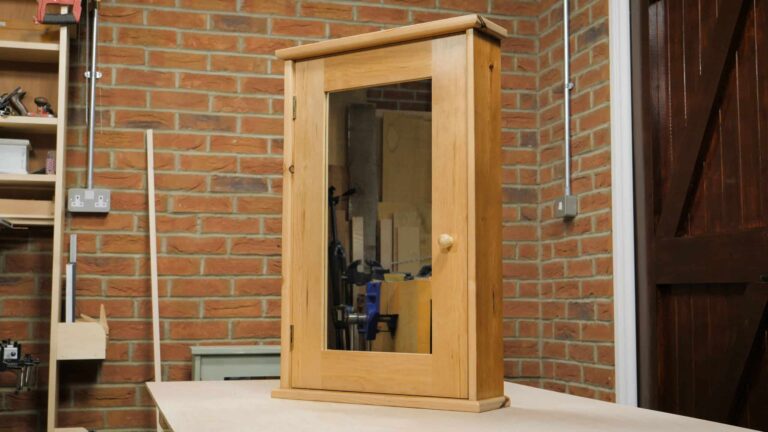

Bathroom Cabinet: Episode 7

A turned nob makes a great addition to a cabinet and Paul takes us through the full turning process so you can make your own. Then the finish is applied to the cabinet before a catch and the handle are fitted to finish off the project.