Blanket Chest: Episode 6

Posted 2 May 2018

This is an episode in a paid series. Want to watch it? You just need to sign up as a paid member, and you can enjoy this video and many other videos we think you will love.

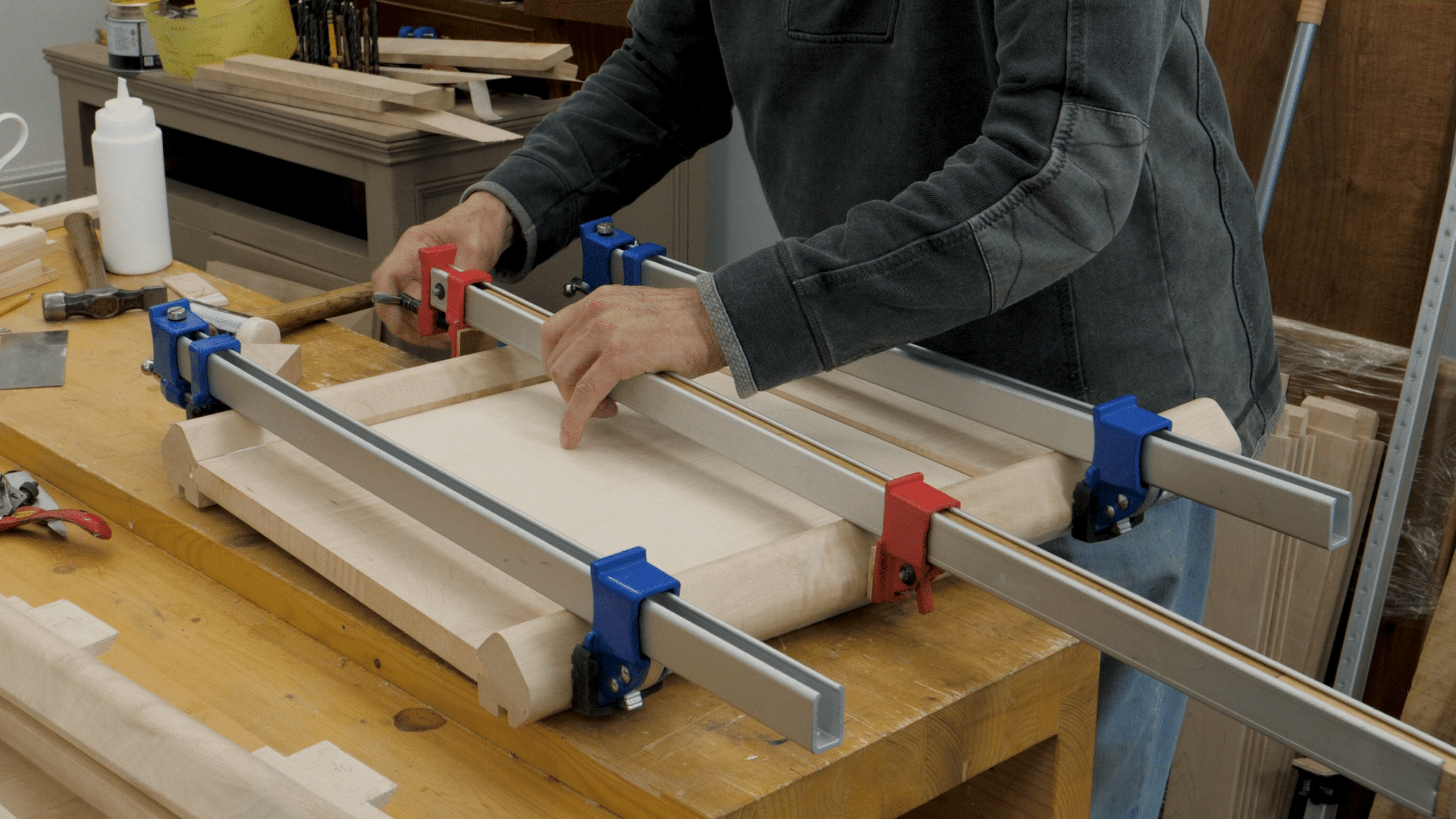

Paul has decided to glue up the carcass in two stages, starting with the end frames and using alignment pieces to keep everything square. Then the whole carcass is glued together, taking special care to ensure all the joints seat making combined use of the clamp and hammer.

That was a challenging glue-up (even to watch). I need a cup of Kava tea to settle down..

That was an impressive glue up.

Paul, I just noticed a new style of clamp used during the glue-up of the end frames. They seem to have rubber pads vs the wood ones of the others. Also noticed no wood reinforcement down the center. Would you let us know the brand and where they are available?

Those are Juuma sash clamps.

Paul wrote about them in a blog article here: https://paulsellers.com/2015/11/a-clamp-in-time/

You can buy some here: https://www.fine-tools.com/tuerenspanner.html

Benjamin. The bar clamps are Jumma. I found them on Finetools.com. I hope that helps.

I noticed as well.

Find them here: https://www.fine-tools.com/tuerenspanner.html

Definitely an upgrade on the cheap ones I’ve got, but also three times the cost…

I’m still using my cheap Asian sash clamps with squares of leather (belt from the thrift store) attached with dbl-sided tape. Like you said, a third of the cost.

Coach Jimmy V’s words ring true in all things in life.

“Don’t give up, never give up!”

Sorry for the misquote. Coach’s quote is:

“Don’t give up. Don’t ever give up.”

Glue ups are fun! 😉

Looking forward to seeing how to handle that ooze of glue going down (up?) the front panel. That looks like the type of problem I would have but then would have no idea how to remove and know that my panel is still floating. Or whether its something to even worry over.

Paul scraped this off with the edge of a chisel as soon as we finished filming and he walked around the other side of the chest. Be careful to remove the glue from your chisel immediately afterwards if you do this.

I don’t understand what the alignment pieces did. Their tenons are smaller than the mortises, so they don’t register the two sides vertically relative to each other. The two sides are rigidly clamped when we put in the alignment pieces, so it doesn’t seem they can move anything into position. Would you please give some examples of problems they would catch and what you would see?

Yep, I was thinking the same. Couldn’t see any purpose to them.

I answered this in a blog this evening, Ed.

Thank you. It makes perfect sense now!

Could you comment on Paul’s decision to glue up the ends first as opposed to the front and back? I’m guessing it just has to do with the size and weight of the assembly. Also, are the alignment pieces there to help counteract the tendency of the clamps to cause the inside shoulder lines to open up since the clamps can’t be centered on the tenons?

That’s right Harry. Because the leg sections are canted and not square on with flat faces the tendency would be for the legs to twist under the clamp pressures.

Thanks Paul. I read your blog and that’s great foresight on your part. I think this simple technique will avoid a lot of headaches.

I was sweating there watching Paul struggle with that glue up! Wow I can only imagine if that was me ….

Which reminds me, I sometimes ask a friend to come over and help with a difficult glue up. It makes you know what you are doing because you have to explain it to them before you get going. It also forces you to label everything clearly because they are more afraid of screwing up than you are. Then you go twice as fast with four hands working. So it is much less stressful with more time for the tricky spots. Then you have someone to admire the piece and drink a beer with while the glue is drying.

32:00 the hammer blows sound like the Quake III Arena intro heh.

Very exciting to see it all come together so perfectly

Doing the gluing in 2 steps is the best strategy. However if there is a reason Mr Sellers glues the short end pieces first instead of the long ones. I would have thought it is easier to handle the short pieces for the second gluing phase

Hi Luc,

I passed your question on to Paul and his answer is below:

I don’t think it makes any difference personally, that is just the way I chose to do it.

Kind Regards,

Izzy

And I thought my glue ups were adventurous!

Just watched your excellent video and noticed the size of your artisan’s hands . I am a 78 year old lifetime guitar player and my hands , although not as big as Joe Walsh’s , are as big and as useful as the hands of my coal miner father .

A couple of years ago I unsubscribed from Paul’s videos because so many of his projects were geared toward beginner woodworkers, and I am not a beginner woodworker. Recently, this video was put in the public domain, and I am tempted to re-subscribe. Every experienced woodworker who has watched this video knows that Paul Sellers is a man with remarkable skills, tenacity, and drive. This entire project is one of the most impressive displays of master craftsmanship I’ve ever seen. If you don’t believe me, buy some sycamore and use a Record 044 to plow a groove on the edge of a rail and do this with (almost) no tearout. After that, try and do a glue-up like the one we say in this video.

Bravo, Sir.