Occasional Table: Info Page

Posted 14 October 2014

This is the introductory page for a paid video series. Want to watch more of this project? Select the best option below to get started.

Description

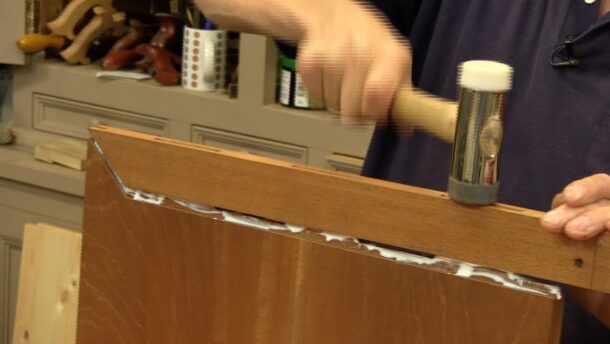

In this project, Paul takes apart a secondhand mahogany table to look at the construction methods used by craftsman in the 17th and 18th century. Applying his discoveries, Paul makes another table to make a matching pair, which trains you and preserves the working skills in the lives of future craftsmen and women.

Tools needed:

- Knife

- Square

- Combination gauge (or marking gauge and mortise gauge)

- Tape/Ruler (or both)

- Sliding bevel

- Chisel hammer

- Chisels (at least 1/4″, 3/8″, 1/2″, 3/4″ and 1″)

- Gouge

- Hand router (see how to make a ‘Poor Man’s Router here)

- Smoothing plane (No 4)

- Jack Plane * (No 5) (recommended if using rough sawn)

- Spokeshave

- Scrub Plane *

- Mortice guide

- Winding Sticks

- Handsaw

- Tenon saw

- No 80 Cabinet Scraper

- Card scraper

- Brace & bit/drill driver

- Rasp/file*

- Screwdriver

* = optional

The joints used in this project:

Angled shoulder mortise & tenon

ok … how am I gonna sleep now …

Paul,

I am really looking forward to this one. I have made the occasional table from the foundation course here in the US at your old Texas location and see a lot of similarities with this table, and a lot of differences as well. I like the idea of the splayed legs and the breadboard/mitered/haunch tenon top. Cant wait.

Just by looking at the introduction I can see there will be a lot of learning here. This is so spooky. I made a bid in a auction last night for a plank table I am going to disassemble if I win the bid. Then this turns up today. Coincidence? .

What a great surprise. I am really looking forward to this one. And Greg, wonderful drawings, as always!

Exciting! Ive got some old iroko worktops that I could use for this. Would that be a good choice of wood (I’ve never worked with it!)?

I believe there is an issue with iroko been an oily wood and not great for glue Chris,but am not a 100% certain

I made a (small) table top from Iroko on my only table top to date. Yes it’s oily but had no problems with glue-up (normal PVA) but it was only a very small table. I found it a bit difficult to plane (grain direction) but maybe that was just me! It’s a really beautiful wood for a table top though. Starts a warm honey yellow and quickly darkens to a warm deep brown!

Hi Chris, I just asked Paul and he said iroko is great for tables.

i’m looking forward to this series, i’m also looking forward to see the techniques used in disassembly, if these are covered maybe i’ll get round to fixing those wobbly dining chairs .

This is awesome. One of my favorite things to do is walk through museums. This is going to be actually living the time period. For anyone who likes history this should be beyond expectations. Thank you Paul and crew!

Paul nice looking table, and am excited about recycling wood for the build, never thought abut looking for used f”wood” furniture to get the wood. This looks like a nice table and again commend you for providing Greg Meritt’s drawings as he does nice work and these drawings are easy to keep in a binder journal.

Steve

With the price of timber sky rocketing this just may prove to be a very useful method indeed.

This project is going to be a real treasure. As others have said, the drawings are excellent and a great enhancement to me at the bench. I’m particularly interested in learning more about laying out and cutting splayed legs – like the stool project. And I will take on the challenge of finding a table to salvage for the build. I’m still attending a local wood working school, so I won’t have time to build along with you, but as soon as time allows, this is high on my list for next builds.

I built a similar sized end table last year. Now I get to see the less frustrating way to do it 🙂

Thank you Paul, really looking forward to this project!

Ahhh – this is truly a gift. I’m excitedly looking forward to this series.

I love stuff like this. Taking something apart to see how it’s made.