Dovetail Boxes: Project Info

Posted 2 January 2013

This is the introductory page for a paid video series. Want to watch more of this project? Select the best option below to get started.

For a beginner friendly step-by-step guide on how to make a Chisel Tray, see our sister sister Common Woodworking.

Boxes – skills in making dovetail Joints

These boxes are an extension of pieces Paul has designed specifically to develop your skills over the next few weeks and months. By the end of one year you will be able to tackle all kinds of boxes ranging from this chisel tray to a complex tool chest like this. In between there are other boxes with hinged lids, fall-fronts, and sliding closures. Within each progressive phase, we will include concepts of design from a designer craftsman’s perspective. That way, construction and methods behind construction become integral from a working knowledge and more readily transposed into visually distinctive pieces.

Parts and cutting list

Cutting List for the first box the ‘Chisel Tray’

| Sides x 2 (thickness 1/2″[13mm]) | 2 x 12 ¾ | 51 x 324 |

| Bottom x 1 (thickness 3/8″[10mm]) | 5¾ x 13¼ | 146 x 337 |

| Ends x 2 (thickness 1/2″[13mm]) | 2 x 5¼ | 51 x 133 |

Tools/materials/equipment needed

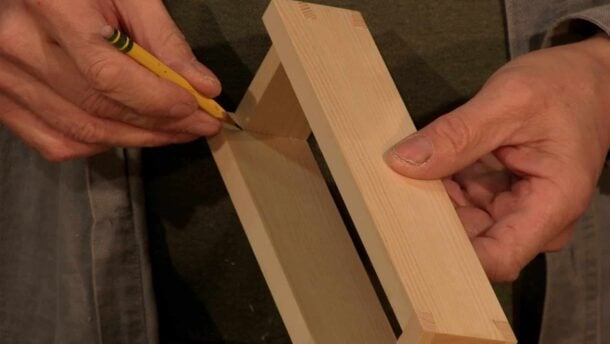

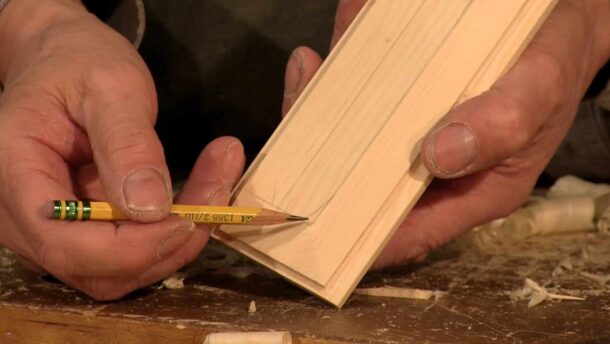

The tools we use to make this project are quite common, minimal and yet essentially fundamental to all joinery types. Most of the tools below are simply part of the set you will need for all dovetailing in the future. The essential element to all joinery is a keen knife edge, an accurate square and sharp chisels.

| Tools/equipment/supplies | Knife Square Marking gauge Chisel hammer Chisel Router Tape Smoothing plane Handsaw Tenon saw Workbench Sandpaper (1 x sheet of 120-150 grit & 1 x sheet of 220-250 grit) 1-1½” Natural Bristle Brush |

| Wood | A few square feet of 1/2″ (13mm) and 3/8″ (10mm) pine or other wood |

| Finish | Shellac (Zinsser [USA] Liberon [UK]) |

With these small box projects, it would be great if you could address resawing by hand.

Do you like the clear or amber colored Zinsser shellac on spruce or pine?

After applying the Shellac finish, are you supposed to rub it with 0000 steel wool? Fine grit sand paper? Or something else?

Kelly

Take a look at this website. I’ve used Jeff’s method with steel wool, mineral spirits and paste wax – it works great. When you load up the wool with the paste, dip it in a few drops of spirits then rub out the shellac.

http://www.homesteadfinishingproducts.com/htdocs/shellac.htm

Mark

Firstly, really impressed with the quality of the videos and instruction, BUT…

Any ideas on where to source pine in these thicknesses, in the London area or more generally, please? I’m assuming these are finished rather than nominal sizes. The big DIY stores tend to be 18mm and upwards, and mostly shaped like bananas. My local timber yard will do 8mm, 15mm and upwards, which may work at a pinch, but trying to avoid excessive planing or resawing before I get to start the actual project… Many thanks.

This is going to sound pretty stupid but…

When you say handsaw – what specifically do you mean? I have a tenon saw but I thought tenon, dovetail, flush-saw’s etc were all classes of handsaw?

Thank you 🙂

They are all handsaws, but ultimately you do have to have a non generic name for each one of them. Anything with a brass back can generically be referred to as a tenon saw, but small ones tend to be called a dovetail saw unless it’s small and has an inline handle rather than a pistol-grip handle and then we call the inline saw a gents saw and the other a dovetail saw even though they will both do the same tasks.Tenon saws tend to settle in sizes between 10-14 but dovetail saws, going from 6-10, crossover at 10″ into tenon saw category too. Back saw tends to be an Americanism and rarely do Americans use the term tenon saw. Recently people have been referring to sash saws and carcass saws in the ranh=ge of tenon saws, but that was not a common practise “in the trade.” Mostly it was gents, dovetail and tenon saw for all back saws.

Thank you 🙂

So it sounds like the “handsaw” in the list above isn’t in addition to the tenon saw, but more of a “you’ll need a handsaw, and I suggest a tenon saw”?

PS: Thank you so much for sharing all of this knowledge. By the time I realised woodwork would be great to know, my granddad (a master joiner) was too old to teach. If I had the funds I’d be at your next Penrhyn castle workshop like a shot! It’s very reasonably priced, but still… can’t afford just yet 🙂 Maybe the next one.

Matt,

I’m sure someone will correct me if I’m wrong but, I think I’ve figured this one out. 🙂

It seems the term “hand saw” is used in many ways. From what I’ve read, it is supposed to refer to the ones that are about 24″ or longer and, do not have a spine. A Panel saw looks like a hand saw but, it’s shorter, 18 to 20″ long. A tenon saw (aka back saw) is a general term used to refer to a saw that does have a spine.

From there, you can get into more specific names within each category. But, it seems the terms are misused a lot.

The link below has some good information.

The Disston Saw Institute

http://www.disstonianinstitute.com/

The Disston Saw Institute

Links to Relevant Websites and Vendors

http://www.disstonianinstitute.com/links.html

Cheers for the explanation and links 🙂

Well, just when I think I might be catching on …there’s more to learn. lol

Hi,

I am looking for the cutting list for the 2nd dovetail box – the one with the sliding top. In particular I would love details on the difference between the first and 2nd box to see the dimensions of the cut that allows for the top. I know this is in the video but would be nice to have it all in one place.

Thanks!

Eric

Drawings per the series…

https://woodworkingmasterclasses.com/discussions/topic/dovetail-boxes-reference-sheets/

Thanks for the quick response.

Greg, that’s excellent – just what I needed. That helps me see what I am going to build before I start, without having to watch the entire series first. So helpful, and much appreciated.

Eric

For anyone in the UK who’s after timber to make these boxes and is struggling to find stuff close to final thickness, the supplier you need is B&Q. Specifically, the ‘pine stripwood’ section. That’s where I’ve been picking up the timber to make the boxes we made on the course. You’ll need to have a good rummage through the racks to find pieces that aren’t twisted or have a join but it’s generally plenty good enough for boxes and takes minimal work to get square. Hope this helps someone else as much as it helped me!

Hardwood is very different ballgame and you’ll need to hit up eBay and look for 1/2″ stock, or find a local yard (or local WWMC member with a bandsaw!) to resaw any hardwoods you can get if you don’t want to do it by hand.

Happy dovetailing!

George.

I tend to find my timber in skips in the form of 1930 panel doors these were made from pitch pine …I picked up eight recently. Beautiful 1/4 cut timber. No knots ..close straight grain.

The last person said about supply of thin timber, I cut this down with a rip saw to 1/4 and planed it to 1/8 perfect stuff for pencil boxes

I tend to find my timber in skips in the form of 1930 panel doors these were made from pitch pine …I picked up eight recently. Beautiful 1/4 cut timber. No knots ..close straight grain.

The last person said about supply of thin timber, I cut this down with a rip saw to 3/8″ and plane it to 1/4″ perfect stuff for pencil boxes

I’m overwhelmed by the number of projects. I’m even more overwhelmed by the requirements and specifications. The thin-wood specs are the ones that throw me the most. (and those are the ones I want to do the most.) Starting with this project, dovetailed boxes, it’s well enough to know how. I also want to know “why”!

1. Why are the box bottoms the thinnest wood of all? I can understand trying to keep overall weight low, but most things in the box rest on the bottom piece. Wouldn’t the bottom piece be thicker, stronger, and wouldn’t the fastening method use joints of some type instead of just glue?

2. Why are the side and end pieces different sizes? They are also more difficult to find without having to change thickness. I can source many woods in 1/8″, 1/4″, 1/2″, 3/4″, and 1″ (4/4). It’s those danged 3/8″ and 5/8″ and 7/8” (apologies to my European friends) thicknesses that throws me. Hard to find ready to use in the wood I might want, and honestly seems more difficult to, for instance, plane accurately down from the next size up.

3. Wouldn’t it be easier to have the same thickness on all four sides of the box? Wouldn’t it be simpler to cut dovetails in pieces that are all, say, 1/2″ thick? (I see the merit in using the actual wood to measure the size of a pin, but first I have to cut the sides, front and back to length.

4. Can I simply change the cut list to all 1/2″ thick? That way, the lengths are all sized to fit the outside dimensions of the box. Isn’t it harder to calculate board lengths when one board in a joint is 5/8″ thick and the other part of the joint is 1/2″ (4/8″) thick. Is it structurally better, or just a matter of appearance?

I have to admit that I was probably absent that one day in elementary school when fractions were introduced. But, after calculating a cut list for one size of box, changing the overall box size makes me want to use a computer spreadsheet. I’d rather not.

Summary Questions: Can I simply take the first box and use 1/2″ wood all around? Will it fall apart? Look terrible? Will it change Paul Sellers’ step-by-step instructions? And, if I happen to have to plane a thickness to be a bit smaller, can’t I simply use Mr. Sellers’ methods to compensate for using 7/16″ thick wood at those two joints, without tearing out my ever-disappearing hair because it isn’t precisely 1/2″ thick.

Perplexed as always, Jeff.

Well I’m no more qualified to answer your questions than you are, but they’re similar to concerns that I had, so I’ll give you my thoughts.

Greg’s drawings (link in the comments here), give thicknesses for both sides and ends as 1/2 inch, with the bottom as 3/8. So you can use 1/2 inch all round and nothing will fall apart.

I’ve made a few of these boxes and with various thicknesses. A great thing about the method taught here (which uses the actual dimensions of the wood being used to mark for example the pin depth) is that it will work even if every wall of the box is a different thickness.

So now my choice is just either what I have, or aesthetic.

I did get caught out going too thin because the hinge hardware needed more meat in the wood, and dovetails in _really_ thin stock don’t look good but other than that I think you just need to decide on the look you want. For me having the sides fractionally thicker than the front and back is a good look.

I would not worry about the thickness of the base – for normal contents (chisels, candles or pencils for example), 3/8 and PVA will be fine.

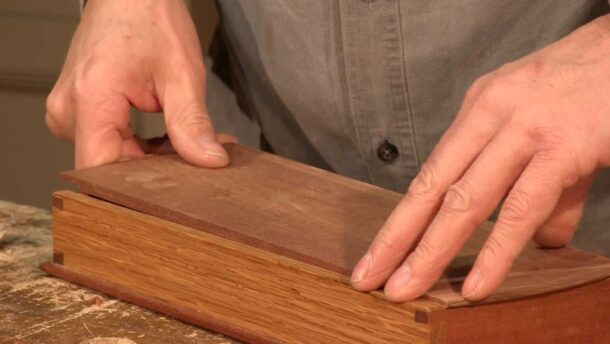

Completed the first box in 1 day here are some pictures.

Made with Mexican pine and finished with shellac and wax

https://photos.app.goo.gl/lZgSmaAEgWrNoMGo2

I love this series as a learning and skill-building exercise where we get something functional in the process.

I believe the above dimensions are for the 1st box; does anyone know if drawings or dimensions for the any of these 3 boxes have been posted somewhere? Thanks.

Hi Paul (& team),

Great videos and really useful but I can’t find them on your YouTube channel. Is there anyway episodes 4-8 could be uploaded so I can continue to develop my dovetail box making.

Many Thanks

Nige

Well, after all this time waiting, I’ve started my workbench build, however, after cutting the bench top to size, I have a large laminated portion I turned into a small floating workbench… I screwed a stop down, I have a cheap 6-inch vise attached, and I clamp it to a large surface…

I can finally begin practicing dovetails! I’ve reached my next issue, though, and that is Home Depot pine. This pine, even the high quality/select appearance boards they have, seem to be remarkably different from the pine shown here and often used on the site. I recall Paul saying that US and UK pine are different, but I didn’t think to the point of almost unworkability. I can dent the wood with a light fingernail pressure.

Is this type of US pine unsuitable for woodworking projects like these, or do I stink at woodworking still? I’m considering switching over to always using hardwoods, oak or ash, in place of US pine when it’s called for…

I asked Paul and his reply is below:

All woodworkers face this issue living on different continents. Pines are different to one another and even the same species can have different characteristics as in growth ring distances, densities etc. Just par for the woodworking courses we take. The softer pone is usually eastern white pine which though soft is still enjoyable to work with. The Shakers made most of their pine furniture from Eastern White pine.

Having been a “lurker” for a couple of years, I thought I would bite the bullet and start improving my hand tool skills by building all these projects by hand. Starting with his items that are both CommonWoodworking.com and here, so the small dovetail box is first. Really enjoying myself and I’ve progressed on my box through videos 1 & 2. Great job!